Surface carboxyl functionalized polystyrene / nano silicon dioxide hybridization material and preparation thereof

A nano-silica, carboxyl functionalization technology, applied in the field of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

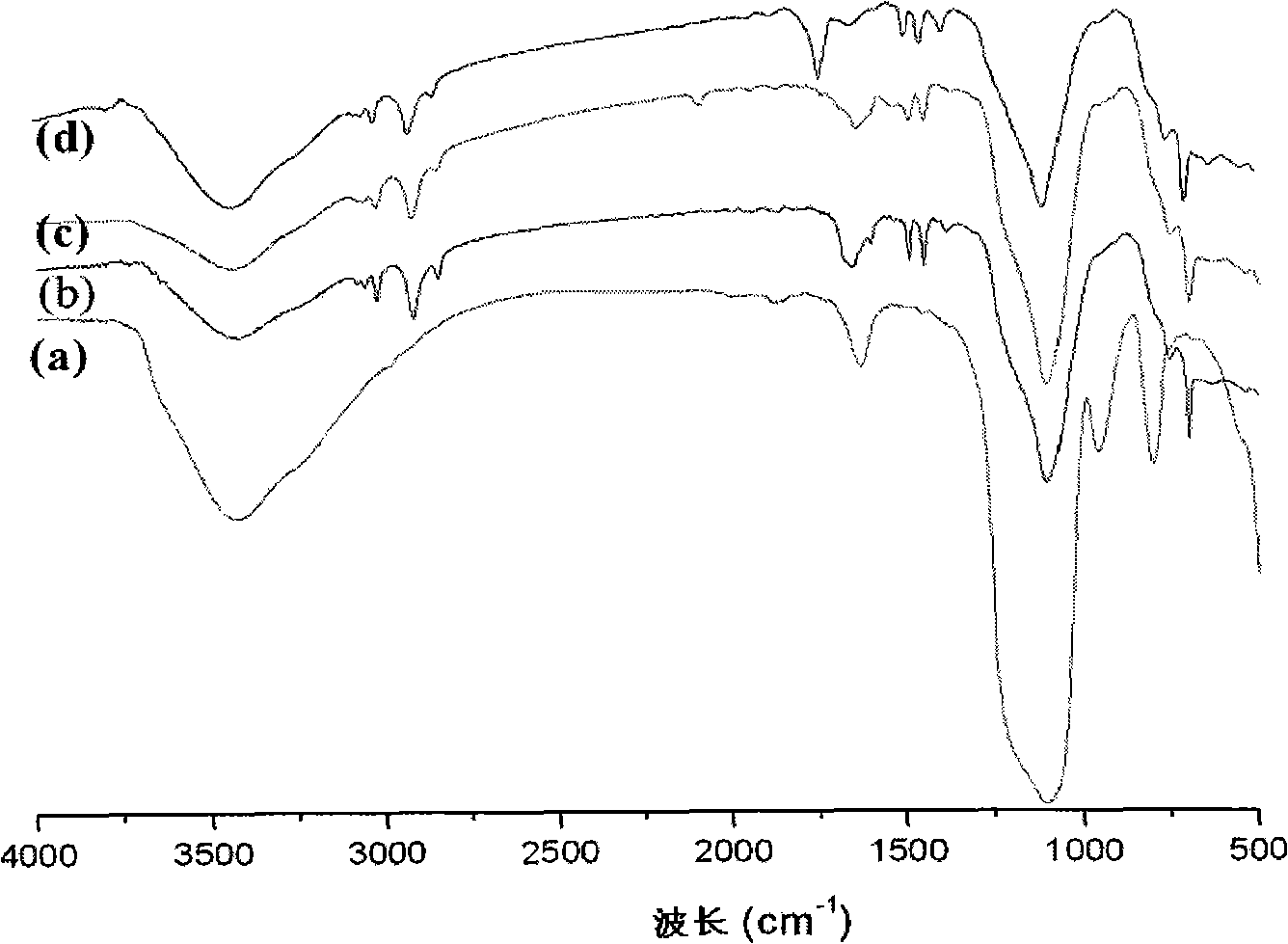

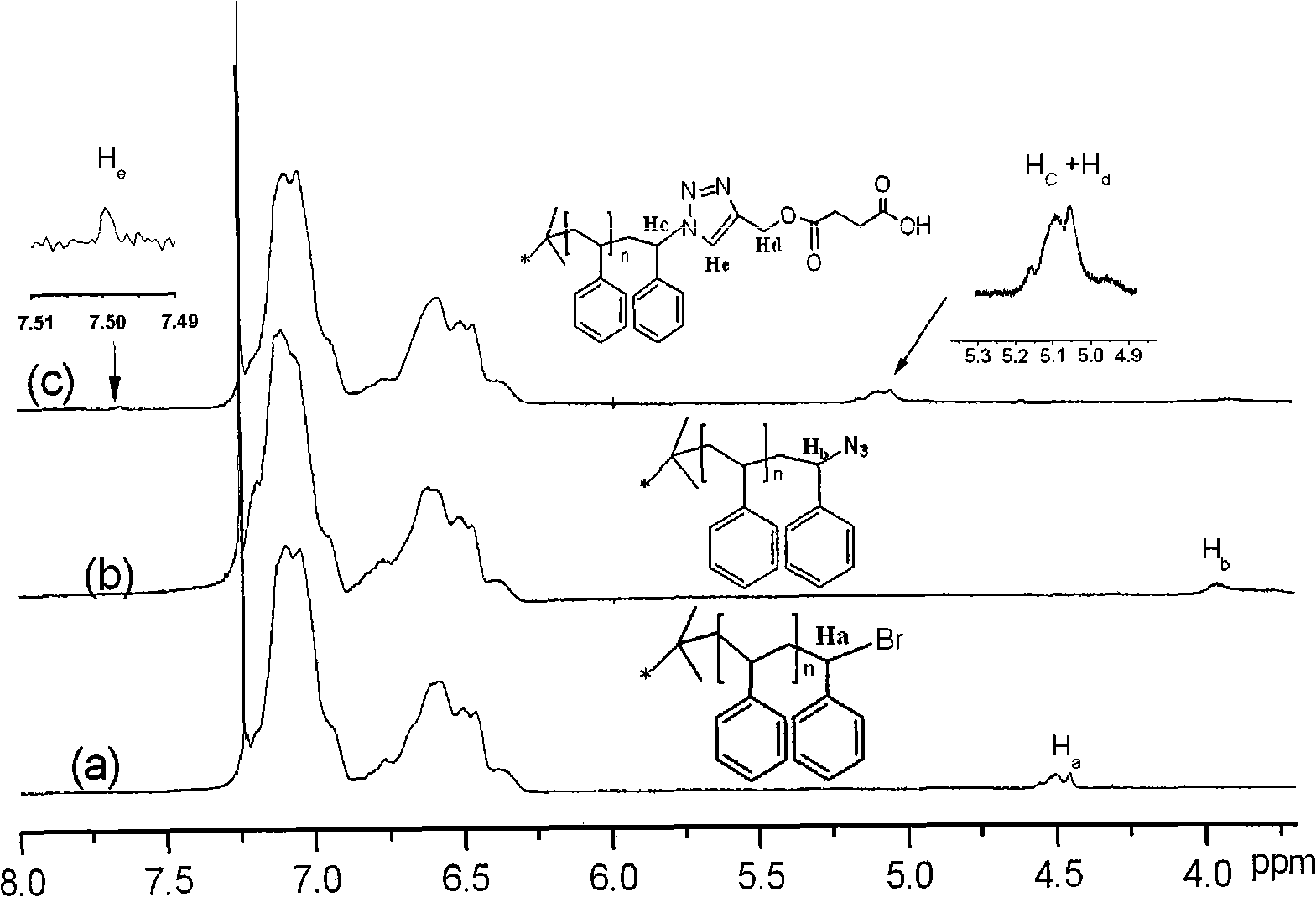

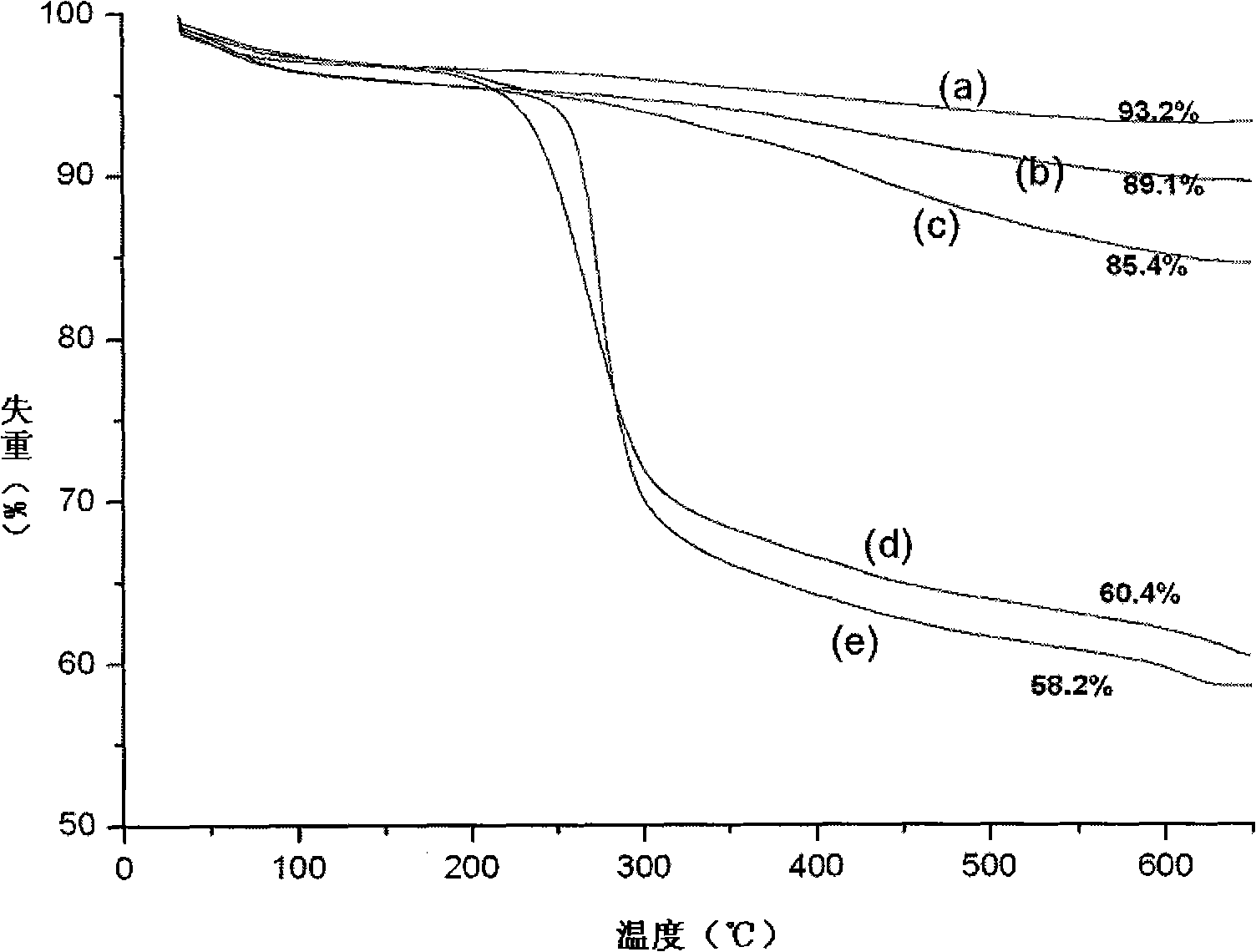

[0056] (1) Terminal azido-based polystyrene / nano-silica particles

[0057] Add 5g of nano-silica particles to a 50ml round-bottomed flask, dry 30ml of toluene, ultrasonically disperse for 30min, add 40mmol of aminopropyltriethoxysilane coupling agent, and heat to reflux for 10h. After the reaction was completed, it was centrifuged at a speed of 4800 rpm, washed several times with chloroform, and then washed several times with ethanol. Nanoparticles were vacuum-dried at 40°C for 24 h, and recorded as surface-ammoniated silica particles (SiO 2 -NH 2 ). The above 1g SiO 2 -NH 2 Disperse the particles in 30ml of anhydrous acetonitrile, stir in an ice bath for 2 hours, then add 2mmol of triethylamine dropwise, continue stirring in an ice bath for 40 minutes, then add 2mmol of α-bromoisobutyl bromide dropwise, stir and react in an ice bath for 6 hours, then room temperature Stir the reaction for 24 hours to end the reaction, filter, and wash the product with saturated NaCl solu...

Embodiment 2

[0063] (1) Terminal azido-based polystyrene / nano-silica particles

[0064] Add 5g of nano-silica particles and 30ml of absolute ethanol to a 50ml round-bottomed flask, ultrasonically disperse for 30min, add 40mmol of aminopropyltrimethoxysilane coupling agent, and heat to reflux for 12h. After the reaction was completed, it was centrifuged at a speed of 4800 rpm, washed several times with chloroform, and then washed several times with ethanol. Nanoparticles were vacuum-dried at 40°C for 24 h, and recorded as surface-ammoniated silica particles (SiO 2 -NH 2 ). The above 2g SiO 2 -NH 2 Disperse the particles in 30-50ml of chloroform, stir in ice bath for 4h, add 4mmol triethylamine dropwise, continue stirring in ice bath for 60min, then add dropwise 4mmolα-bromoisobutyl bromide, stir in ice bath for 8h, then normal temperature Stir the reaction for 30 hours to end the reaction, filter, and wash the product with saturated NaCl solution, ethanol, and distilled water, then dry...

Embodiment 3

[0070] (1) Terminal azido-based polystyrene / nano-silica particles

[0071] Add 5g of nano-silica particles to a 50ml round bottom flask, dry 30ml of toluene, ultrasonically disperse for 30min, add 40mmol of aminopropyltriethoxysilane coupling agent, and heat to reflux for 9h. After the reaction was completed, it was centrifuged at a speed of 4800 rpm, washed several times with chloroform, and then washed several times with ethanol. Nanoparticles were vacuum-dried at 40°C for 24 h, and recorded as surface-ammoniated silica particles (SiO 2 -NH 2 ). The above 1.5g SiO 2 -NH 2 Disperse the particles in 45ml of anhydrous acetonitrile, stir in an ice bath for 3 hours, then add 3mmol of triethylamine dropwise, continue stirring in an ice bath for 40 minutes, then add 3mmol of α-bromoisobutyl bromide dropwise, stir in an ice bath for 6 hours, and then add to room temperature Stir the reaction for 24 hours to end the reaction, filter, and wash the product with saturated NaCl solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com