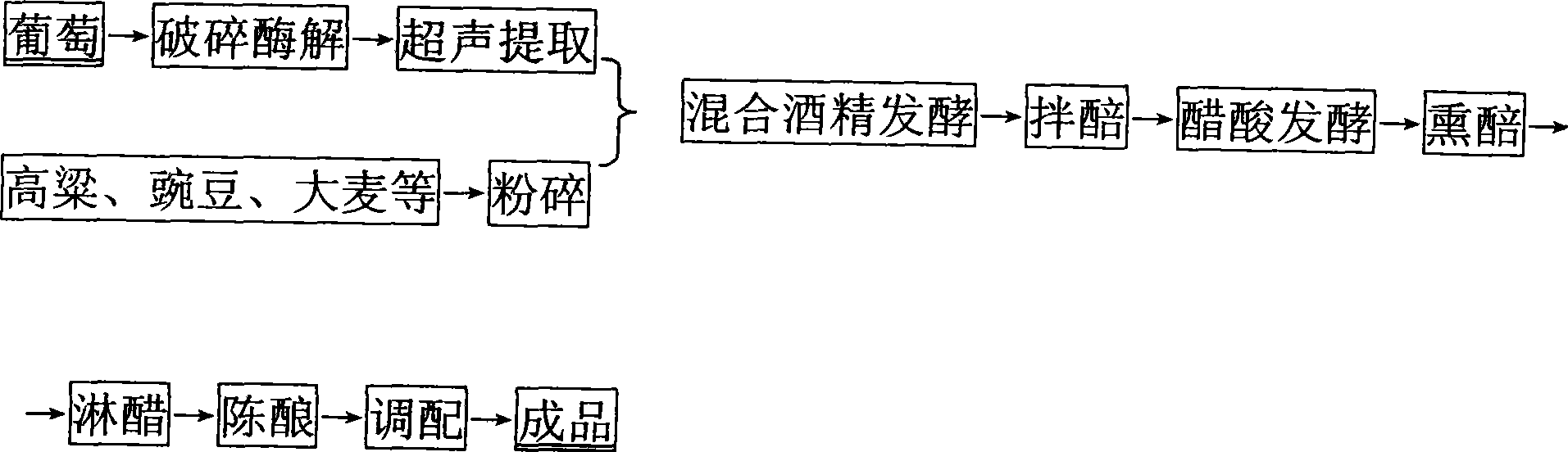

Method for producing grape vinegar by mixed fermentation of grape and grain

A mixed fermentation and grape vinegar technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of simple production process and general flavor, and achieve the effect of dark purple color, clear body and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of grape pulp

[0026] a. Raw material selection: choose varieties with good flavor and juicy. The fruit should be fresh and fully ripe, and the unripe fruit, overripe fruit and mechanically damaged fruit should be removed. It is best to choose grape varieties with high content of resveratrol, proanthocyanidins, tannins, natural pigments and other ingredients.

[0027] b. Cleaning: Wash with water to remove substances that do not meet the requirements of the operation on the surface of the grapes.

[0028] c. Picking and destemming: pick and remove rotten, broken and immature fruits, and remove the stems. The fruit stem accounts for 3% to 8% of the fruit weight, contains 1% to 2.5% tannin, 0.5% to 1.5% acid and a small amount of bitter substances, and can improve the quality of pulp after destemming.

[0029] d. Broken: use a crusher to crush grape fruit (including skin and seeds) until 98% passes through a 10-mesh sieve to obtain grape pulp.

[0030]...

Embodiment 2

[0045] 1. Preparation of grape pulp

[0046] a. raw material selection, b. cleaning, c. selection, destemming, d. crushing, all the same as in Example 1

[0047] e. Preheating: heat the grape pulp to 63°C in the preheater and keep it for 10 minutes.

[0048] f. Enzyme addition: Add 0.01% pectinase preparation and 0.03% cellulase to the grape pulp for enzymolysis for 60 minutes and at a temperature of 48°C.

[0049] g. Ultrasonic extraction conditions: 35°C, 15min, the purpose is to increase the dissolution rate of active ingredients in grape skins and seeds.

[0050] 2. Alcoholic fermentation

[0051] Daqu is used as the saccharification starter, and the ratio of ingredients: the mass ratio of grape pulp (including skin and seeds), grain and Daqu is 4.0:1:0.57. The fermentation temperature is 35°C, the main fermentation is completed in 3 days, the fermentation is continued for 16 days, and the mash is esterified to accumulate various precursor substances for acetic acid fer...

Embodiment 3

[0059] 1. Preparation of grape pulp

[0060] a. raw material selection, b. cleaning, c. selection, destemming, d. crushing, all the same as in Example 1

[0061] e. Preheating: heat the grape pulp to 62°C in the preheater and keep it for 20 minutes.

[0062] f. Enzyme addition: Add 0.05% pectinase preparation and 0.02% cellulase to the grape pulp for enzymolysis time of 40min and temperature of 50°C.

[0063] g. Ultrasonic extraction conditions: 20°C, 15 minutes, the purpose is to increase the dissolution rate of active ingredients in grape skins and seeds.

[0064] 2. Alcoholic fermentation

[0065] Use Daqu as the saccharification starter, and the ratio of ingredients: the mass ratio of grape pulp (including skin and seeds), grain and Daqu is 3:1:0.58. The fermentation temperature is 30°C, the main fermentation is completed in 3 days, the fermentation is continued for 16-17 days, and the mash is esterified to accumulate various precursor substances for acetic acid ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com