Intelligent constant-voltage variable-flow pneumoperitoneum machine

An insufflator and pressure technology, which is applied in therapeutic insufflators, applications, internal bone synthesis, etc., can solve the problems of poor pressure control accuracy, easy excessive overshoot, micro pressure can not be controlled, etc., to eliminate airflow fluctuations , Accurately simulate the effect of pressure in the operating cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

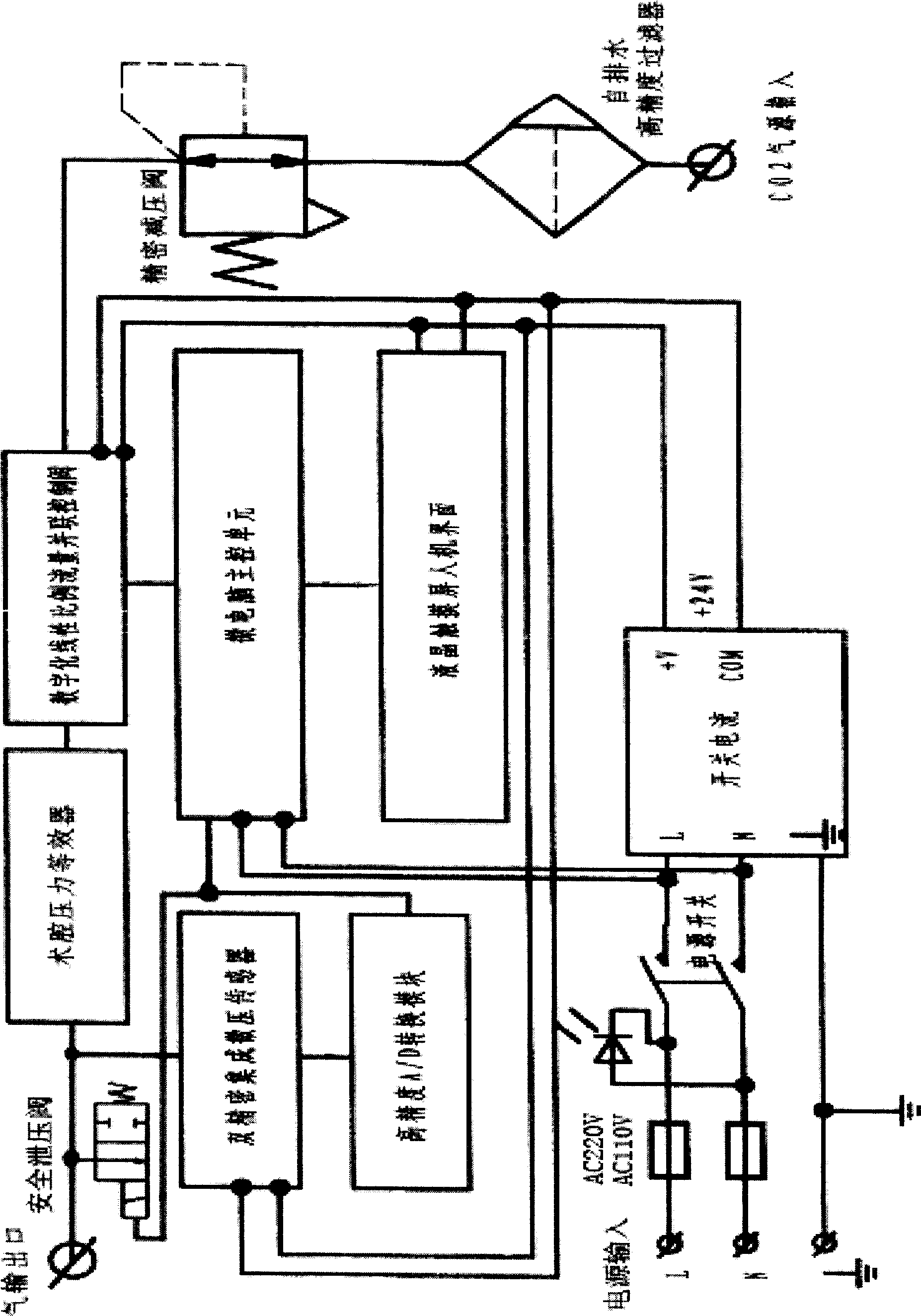

[0085] refer to figure 1 — Figure 12 , Fig. 14, an intelligent constant-pressure variable-flow insufflation machine includes a pressure reducing valve for communicating with an external air source and supplying air to the machine, and also includes: an operating cavity pressure equivalent device with buffering airflow and filtering functions, and the pressure The equivalent device is in the shape of a container and is directly connected to the operating cavity through a gas delivery pipe; the digital linear proportional flow parallel control valve used to control the gas flow to the operating cavity is synchronously connected in parallel by N high-speed solenoid valves controlled by a microcomputer Split flow, N is the number of solenoid valves, N is a natural number and N≥2, each high-speed solenoid valve is connected in series with a precision throttle valve, and the pipeline channel flow rate of the precision throttle valve corresponding to each high-speed solenoid valve ...

Embodiment 2

[0116] refer to figure 1 , Figure 4 , Figure 5 , Figure 9 — Figure 12 , the micro-pressure sensor of this embodiment includes two pressure sensors, the two pressure sensors are connected in parallel, the two pressure sensors are connected to the microcomputer main control unit, and the microcomputer main control unit also includes a A fault processing module that issues an instruction to cut off the flow parallel control valve and open the safety pressure relief valve when the value of the pressure sensor signal is abnormal or the value difference exceeds the limit.

[0117] In this embodiment, dual sensors are used for parallel detection. In order to ensure the stability and reliability of equipment pressure detection, the detection data is first filtered, analyzed and judged to ensure that the data is authentic and credible, and then used for control to ensure the safety, stability and reliability of equipment pressure detection. The pulse-regulated insufflation ma...

Embodiment 3

[0120] refer to figure 1 , Figure 4 , Figure 5 , Figure 9 — Figure 12, The intelligent constant pressure variable flow insufflation machine of this embodiment also includes a self-draining high-precision filter, the air source is connected to the self-draining high-precision filter, and the self-draining high-precision filter is connected to a precision pressure reducing valve.

[0121] This embodiment uses a combination of a self-draining high-precision filter and a precision pressure reducing valve. The self-draining high-precision filter provides clean and dry gas for the operating cavity, prevents impurities from entering the machine, and prolongs the life of the digital linear proportional flow parallel control valve. The precision pressure reducing valve reduces the pressure to about 0.02MPa, provides a precision low pressure source for parallel flow regulation, and ensures the accuracy of flow regulation.

[0122] Other structures and working processes of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com