Preparation of Co3O4 nanotube array

A nanotube array and substrate technology, applied in the field of nanotubes, can solve the problems of long reaction period, complex process, reduced purity, etc., and achieve the effects of low cost, high purity and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

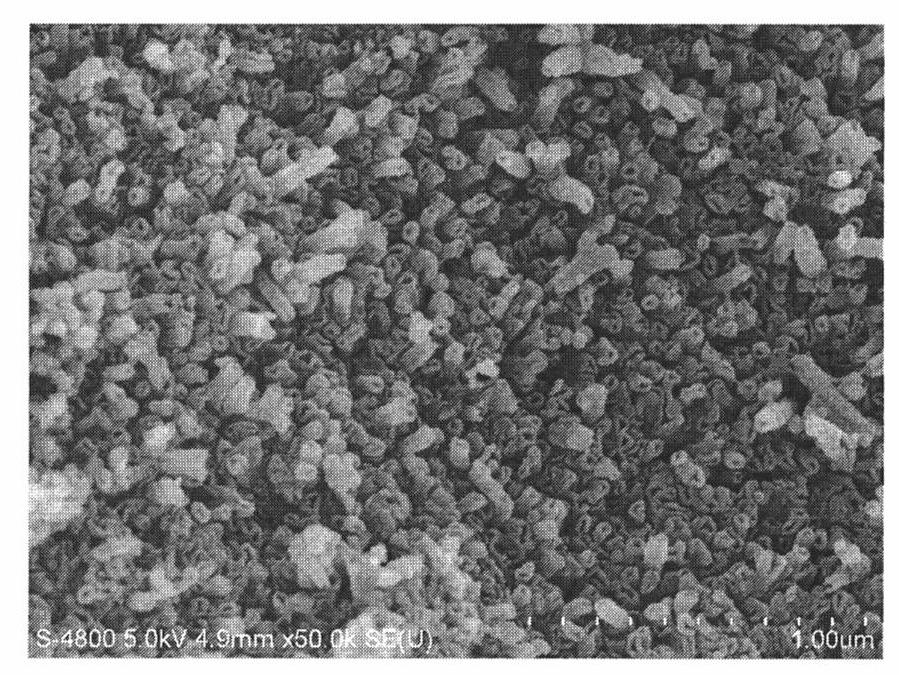

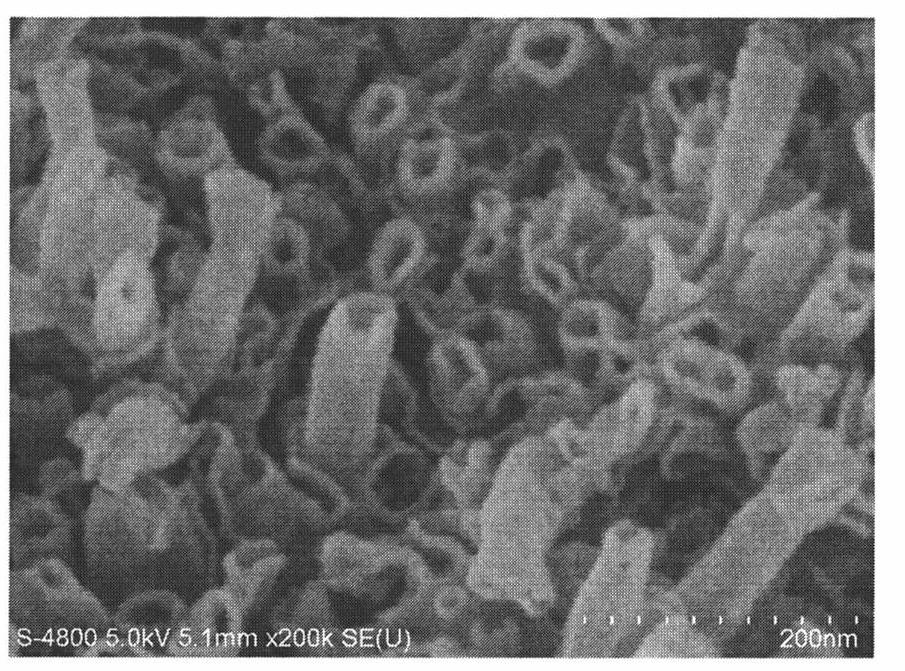

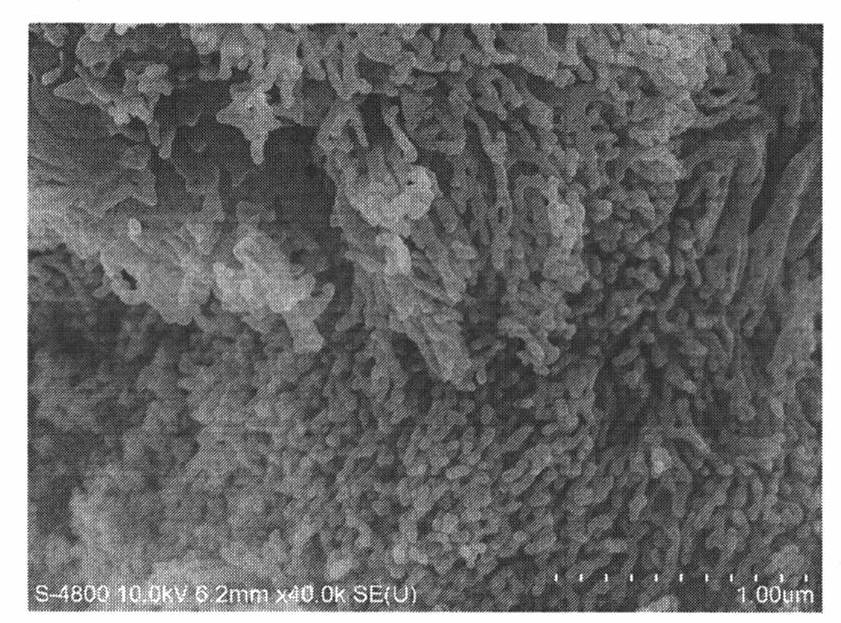

[0027] The iron substrate was cleaned and dried with corrosive solution and acetone, placed on a heating platform and heated at 300°C for 5 minutes. Then spread 0.1 mol cobalt nitrate powder on the substrate and react for 5 hours. The black matter generated by the reaction was washed and filtered, washed several times with deionized water and ethanol, and then dried in an oven at 80° C. for 12 hours. The morphology of the obtained product is as figure 1 and figure 2 Shown is an array of nanotubes. The specific surface area is 41.72m 2 / g.

Embodiment 2

[0029] Using the process in Example 1, when the reaction time is 2 minutes, nanotube arrays can also be obtained.

Embodiment 3

[0031] Using the process in Example 1, when the reaction time is 1 hour, nanotube arrays can also be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com