Nano titanium dioxide electrorheological liquid

A nano-titanium dioxide, electrorheological fluid technology, applied in the direction of lubricating composition and the like, achieves the effects of simple preparation method, good chemical stability and low current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

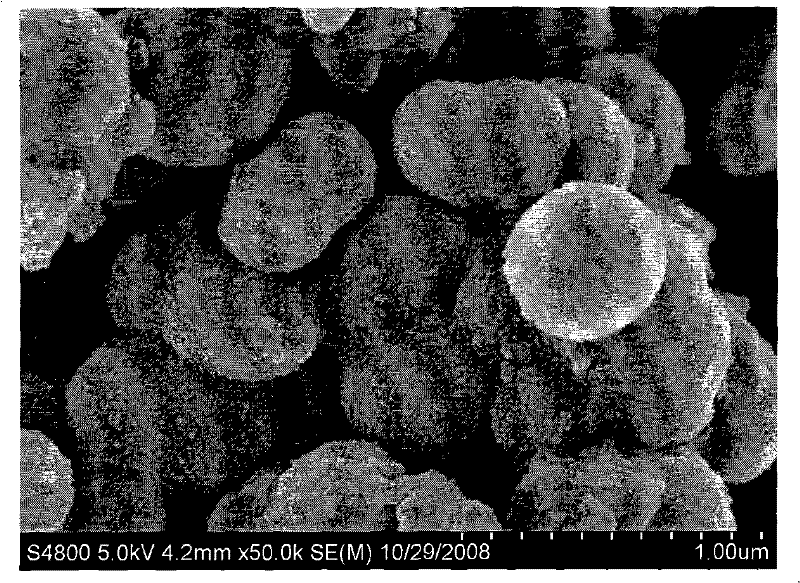

Embodiment 1

[0017] Mix 34ml of tetrabutyl titanate and anhydrous isopropanol at a volume ratio of 1:4, add 0.1mL of glacial acetic acid, and stir well to obtain a stable solution T; mix 1ml of isooctane with 30ml of water to obtain a solution O: Under the condition of stirring, at room temperature, the solution O was added dropwise to the solution T at a volume ratio of T:O=5:1, and a precipitate gradually formed. When the reaction is complete, age the precipitate at room temperature for 10 hours, then wash the precipitate 4 times with deionized water and absolute ethanol, filter, dry in vacuum at 60°C for 20 hours, and dry at 120°C for 4 hours , that is to obtain the desired nanometer size distribution of titanium dioxide particles.

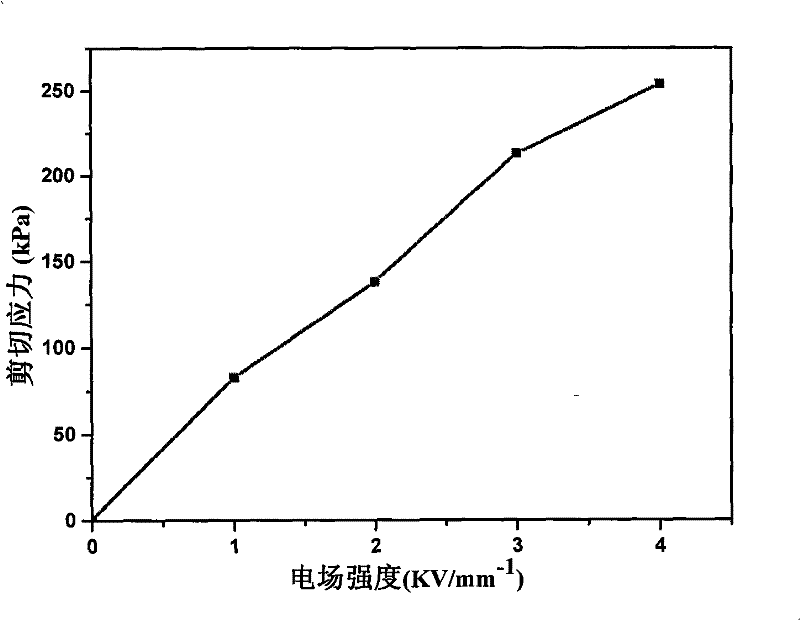

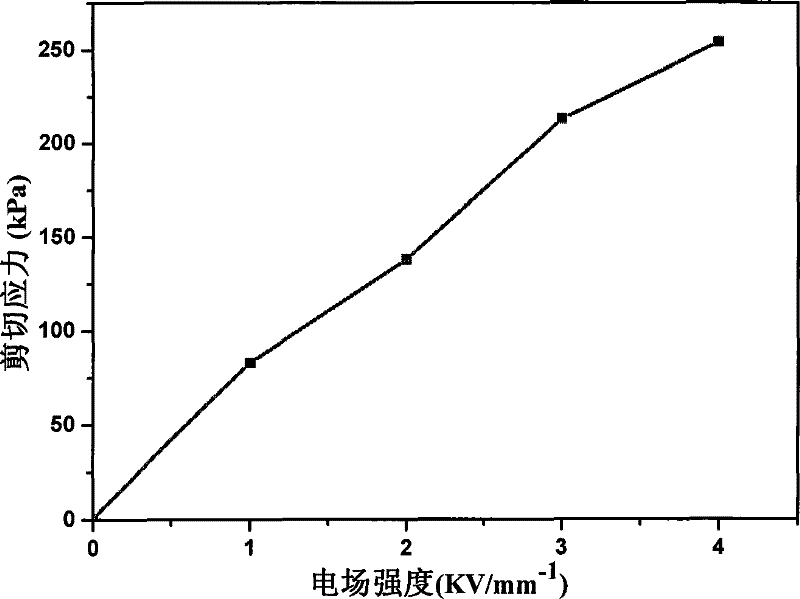

[0018] The titanium dioxide particles with a viscosity of 50mm 2 / s of simethicone oil was evenly mixed to prepare the titanium dioxide electrorheological fluid of the present invention with a volume fraction of 10%. When the applied electric field V=3kV / ...

Embodiment 2

[0020] Mix 34ml of tetrabutyl titanate and anhydrous isopropanol at a volume ratio of 1:7, add 0.1mL of glacial acetic acid, and stir well to obtain a stable solution T; mix 1ml of isooctane with 12.6ml of water to obtain Solution O: Add solution O dropwise to solution T at a volume ratio of T:O=20:1 at room temperature under stirring, and a precipitate gradually forms. After the reaction is complete, age the precipitate at room temperature for 10 hours, then wash the precipitate 4 times with deionized water and absolute ethanol, filter, dry in vacuum at 60°C for 25 hours, and dry at 120°C for 4 hours. That is, titanium dioxide particles with the desired nanometer size distribution are obtained.

[0021] The titanium dioxide particles with a viscosity of 100mm 2 / s simethicone oil is evenly mixed to prepare the titanium dioxide electrorheological fluid of the present invention with a volume fraction of 30%. When the applied electric field V=3kV / mm, the shear strength of 30% ...

Embodiment 3

[0023] Mix 34ml of tetrabutyl titanate and anhydrous isopropanol at a volume ratio of 1:9, add 0.1mL of glacial acetic acid, and stir well to obtain a stable solution T; mix 1ml of isooctane with 19ml of water to obtain a solution O: Under the condition of stirring, at room temperature, the solution O was added dropwise to the solution T at a volume ratio of T:O=17:1, and a precipitate gradually formed. After the reaction is complete, age the precipitate at room temperature for 10 hours, then wash the precipitate 4 times with deionized water and absolute ethanol, filter, dry in vacuum at 60°C for 30 hours, and dry at 120°C for 4 hours. That is, titanium dioxide particles with the desired nanometer size distribution are obtained.

[0024] The titanium dioxide particles with a viscosity of 200mm 2 / s simethicone oil is uniformly mixed to prepare the titanium dioxide electrorheological fluid of the present invention with a volume fraction of 50%. When the applied electric field...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com