Magneto-optic rotation reinforced device

A magneto-optical rotation and optical intensifier technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of increasing the complexity of measuring devices, unfavorable instrument miniaturization, small sample volume, etc., and achieves simple structure, easy production, Effects suitable for integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

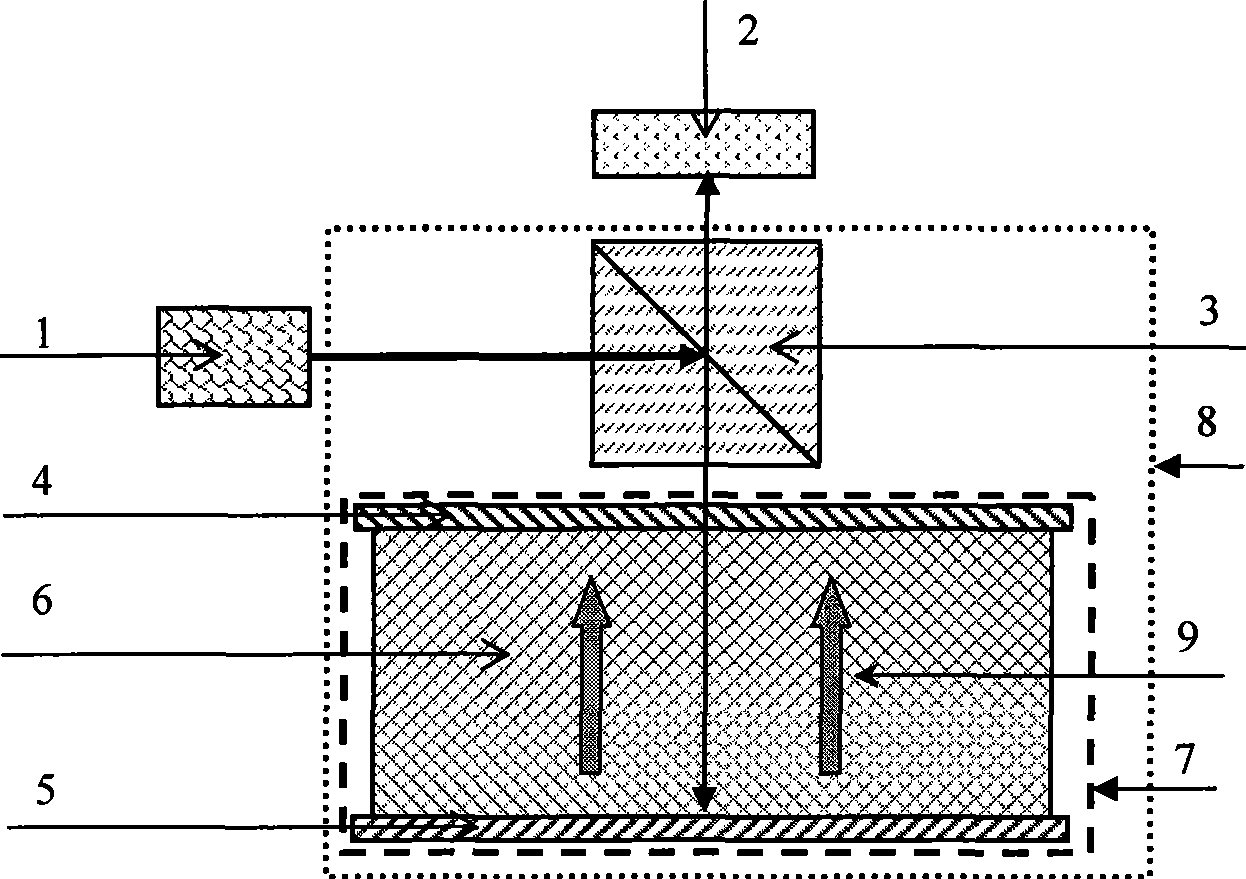

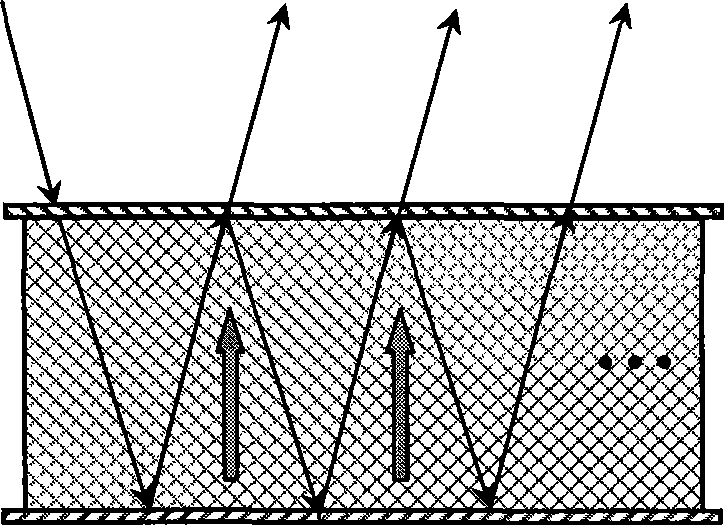

[0024] Specific embodiment 1: The present invention proposes a microfluidic magneto-induced optical rotation enhancement device, the optical rotation enhancer 8 is composed of an optical rotation reflection cavity 7 and a polarization beam splitting prism 3 located outside the optical rotation reflection cavity 7; the optical rotation reflection cavity 7 is composed of The partial reflection mirror 4 and the total reflection mirror 5 placed in parallel and the magneto-optical medium 6 between them are composed. When the optical path through the sample is fixed, a magnetic field 9 is added along the direction of light propagation. According to the non-reciprocity of the magneto-optic effect The sensitivity of measuring the small rotation angle is improved through the optical rotation intensifier 8; the light source 1 is located next to the polarizing beam splitter prism 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com