Curable resin composition and method for forming cured coating film

A technology of curable resin and composition, which is applied in the direction of coating, photoplate-making process coating equipment, pattern surface photoplate-making process, etc., which can solve the problems of uneven coating film thickness and coating film defects, and achieve stable storage good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited by these examples. In addition, the numbers in parentheses after the compound indicate the boiling point at normal pressure. The degree of dispersion is a value of weight average molecular weight Mw / number average molecular weight Mn.

Synthetic example 1

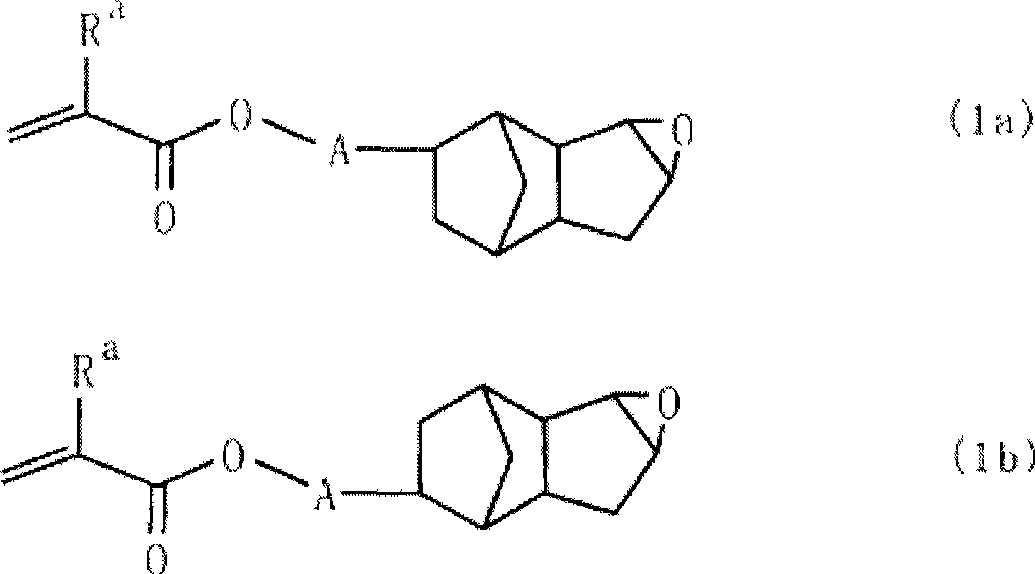

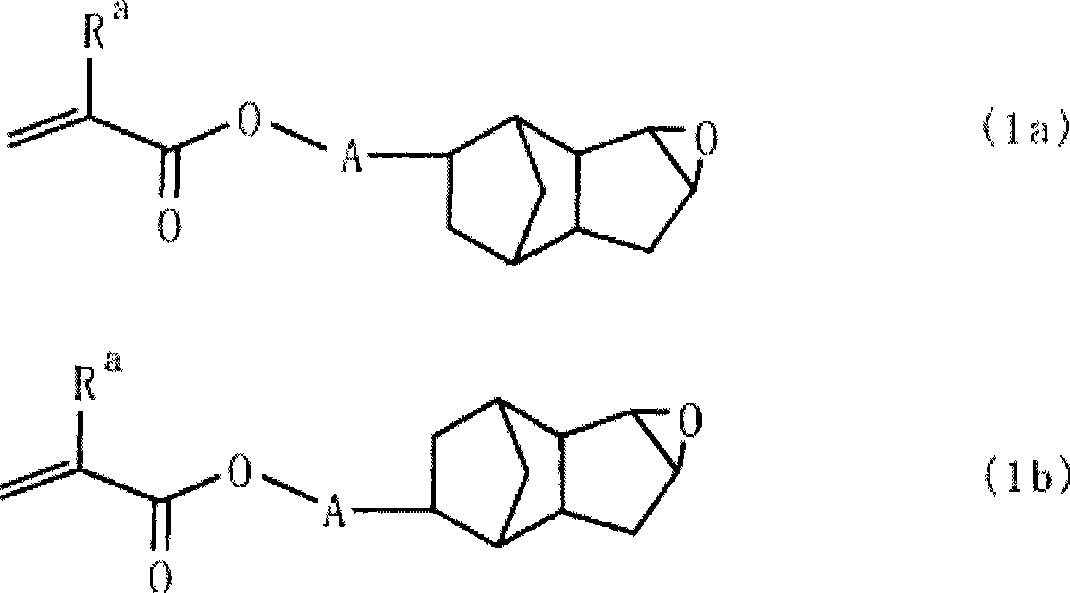

[0101] Pass an appropriate amount of nitrogen into a 1L flask equipped with a reflux cooler, dropping funnel, and stirrer to form a nitrogen atmosphere, add 275 parts by weight of dipropylene glycol dimethyl ether (175° C.), and heat to 70° C. while stirring. Then, use a dripping pump to drop the following solution into the flask in about 4 hours. The solution is 55 parts by weight of methacrylic acid (MAA), 3,4-epoxytricyclo[5.2.1.0 2,6 ]decane-9-yl acrylate and 3,4-epoxytricyclo[5.2.1.0 2,6 ] Decane-8-base acrylate mixture [50:50 (molar ratio)] (E-DCPA) 180 parts by weight, and N-cyclohexylmaleimide (CHMI) 70 parts by weight dissolved in dipropylene glycol Formed in 170 parts by weight of dimethyl ether. On the other hand, a solution containing 2,2'-azobis(2,4-dimethylvaleronitrile) 30 Parts by weight were dissolved in 225 parts by weight of dipropylene glycol dimethyl ether. After the dropwise addition of the polymerization initiator was completed, the same temperature w...

Synthetic example 2

[0103] An appropriate amount of nitrogen was passed through a 1L flask equipped with a reflux cooler, a dropping funnel and a stirrer to form a nitrogen atmosphere, 345 parts by weight of dipropylene glycol dimethyl ether (175° C.) was added, and the mixture was heated to 70° C. while stirring. Then, use a dripping pump to drop the following solution into the flask in about 4 hours, the solution is 76 parts by weight of methacrylic acid (MAA), 3,4-epoxytricyclo[5.2.1.0 2,6 ]decane-9-yl acrylate and 3,4-epoxytricyclo[5.2.1.0 2,6 A mixture of ]decane-8-yl acrylate [50:50 (molar ratio)](E-DCPA) 303 parts by weight was dissolved in 220 parts by weight of dipropylene glycol dimethyl ether. On the other hand, a solution containing 2,2'-azobis(2,4-dimethylvaleronitrile) 70 The parts by weight were dissolved in 293 parts by weight of dipropylene glycol dimethyl ether. After the dropwise addition of the polymerization initiator was completed, the same temperature was maintained for a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com