Oxygen sensitive photoluminescence material, method for preparing the same and uses thereof

A photoluminescent material and oxygen-sensitive technology, which is applied in the direction of luminescent materials, analysis by making materials undergo chemical reactions, chemical instruments and methods, etc., can solve the problems of practical application limitations and high cost, and achieve simple preparation methods and high sensitivity , The effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

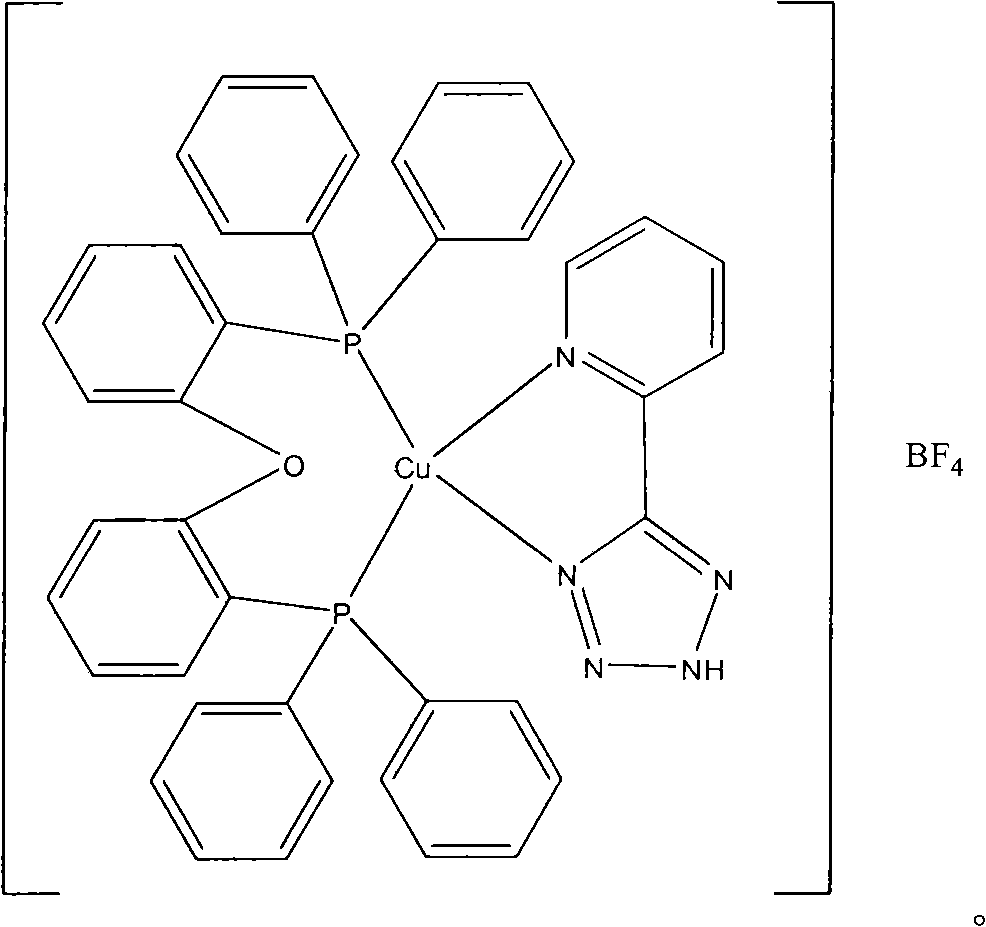

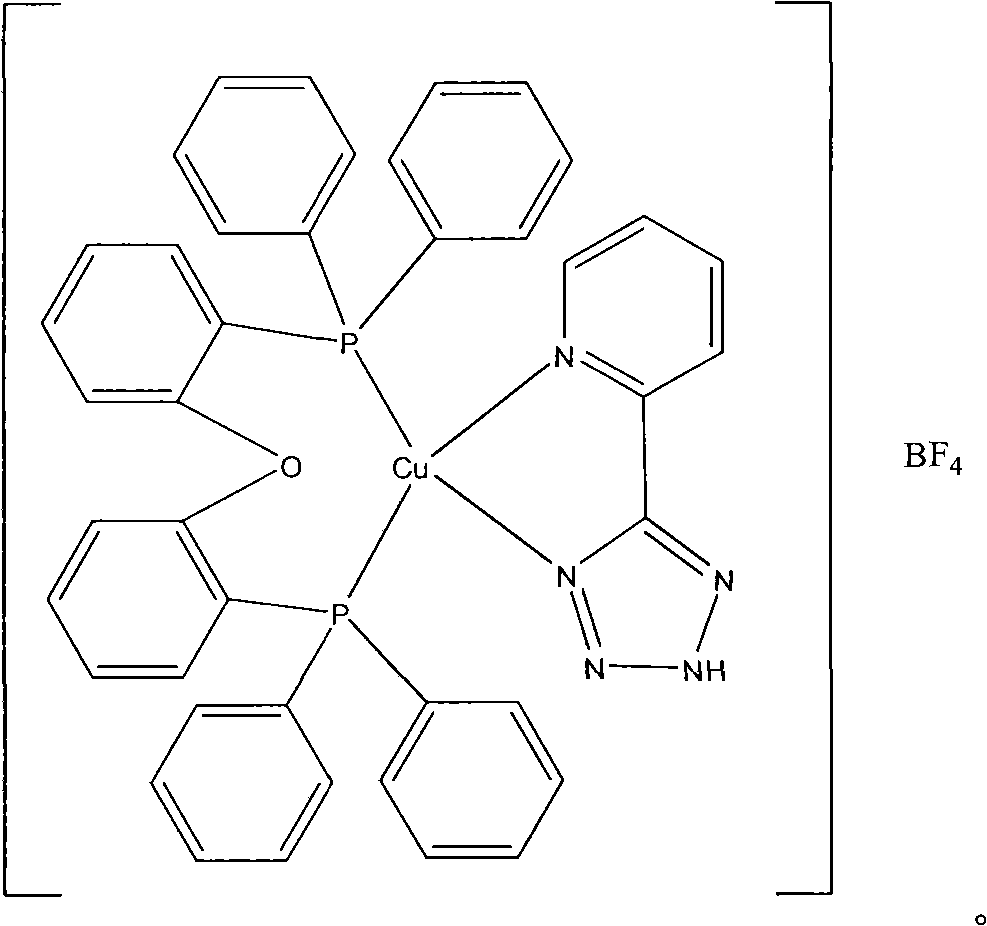

[0019] A [Cu(POP)(PTZ)]BF 4 The preparation of copper complex comprises the following steps:

[0020] a. After dissolving 4 grams of copper fluoroborate hexahydrate in acetonitrile, add 2 grams of copper powder, reflux at 85° C. for 6 hours, remove the copper powder by filtration while hot, and let the filtrate stand still for 12 hours to obtain monovalent copper salt ([Cu(CH 3 EN) 4 ] BF 4 );

[0021] b. 538.6 milligrams of two (2-diphenylphosphino) phenyl ether (POP) and 314. milligrams of [Cu(CH 3 EN) 4 ] BF 4 Dissolve in 10 ml of dichloromethane, stir at room temperature for a period of time, add 5-(2-pyridyl)tetrazole, continue stirring for 1 hour, filter, and evaporate the solvent under reduced pressure to obtain a white copper complex [Cu( POP)(PTZ)]BF 4 .

Embodiment 2

[0023] [Cu(POP)(PTZ)]BF 4 Preparation of / MCM-41 oxygen sensing composite luminescent material.

[0024] Get the copper complex [Cu(POP)(PTZ)] BF that 1mg embodiment 1 makes 4 Dissolve in 5 ml of dichloromethane to form a colorless and transparent solution, then add 100 mg of mesoporous molecular sieve MCM-41 which was heated at 550°C in the air for 6 hours to remove its organic template, and filter after stirring; Wash three times and dry at room temperature to obtain the white assembly [Cu(POP)(PTZ)]BF 4 / MCM-41 composite luminescent material, its copper complex [Cu(POP)(PTZ)]BF 4 The mass ratio to mesoporous molecular sieve MCM-41 is 1:100.

Embodiment 3

[0026] [Cu(POP)(PTZ)]BF 4 Preparation of / MCM-41 oxygen sensing composite luminescent material.

[0027] Get the copper complex [Cu(POP)(PTZ)] BF that 2mg embodiment 1 makes 4 Dissolve in 5 ml of dichloromethane to form a colorless and transparent solution, then add 100 mg of mesoporous molecular sieve MCM-41 which was heated at 550°C in the air for 6 hours to remove its organic template, and filter after stirring; Wash three times and dry at room temperature to obtain the white assembly [Cu(POP)(PTZ)]BF 4 / MCM-41 composite luminescent material, its copper complex [Cu(POP)(PTZ)]BF 4 The mass ratio to mesoporous molecular sieve MCM-41 is 2:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com