Method of preparing pleurotu ostreatus polysaccharide

A technology of oyster mushroom polysaccharide and oyster mushroom is applied in the field of preparation of oyster mushroom polysaccharide, and can solve the problems of difficult control of polysaccharide process, high cost, long period of artificial cultivation of oyster mushroom and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

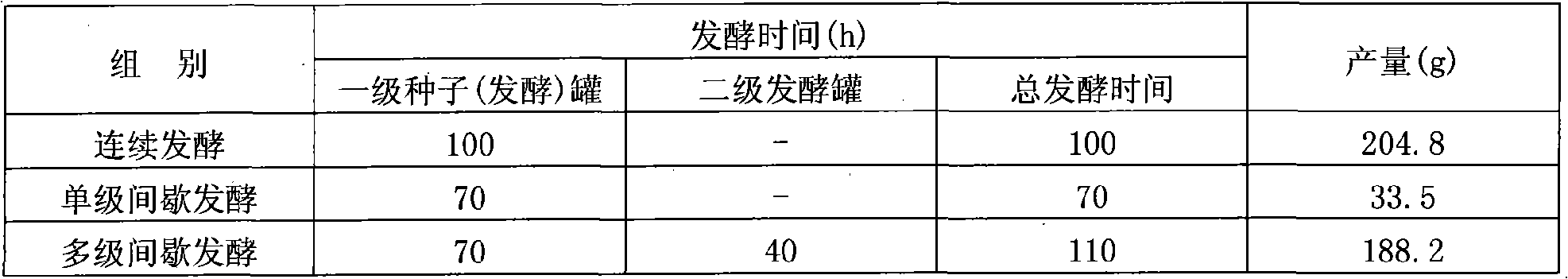

Image

Examples

Embodiment 1

[0092] (1) Activation of slant strains:

[0093] The strains of Pleurotus ostreatus were grafted onto the slant of potato juice comprehensive medium, and cultured at a constant temperature of 24°C for 8 days.

[0094] The selected potato comprehensive medium contains the following substances in weight and volume percentages: 2.0% glucose, 0.1% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 20% potato juice, and 2.0% agar.

[0095] (2) Shake flask seed culture:

[0096] Put 20ml of seed medium in a 50ml triangular flask, sterilize it, connect it to the slant mother seed after cooling, shake it, and co-cultivate it for 5 days;

[0097] Seed medium formula: 3% corn flour, 1% starch, 1% bran, 1% yeast, 0.1% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 0.005% each of vitamin B1 and vitamin B2.

[0098] The conditions for seed culture in shake flasks are as follows: at 25° C., the rotation speed of the shaker is 150 r / min, the amount of liquid in the shake fl...

Embodiment 2

[0109] (1) Activation of slant strains:

[0110] The strains of Pleurotus ostreatus were grafted onto the slant of potato juice comprehensive medium, and cultured at a constant temperature of 24°C for 5 days.

[0111] The selected potato comprehensive medium contains the following substances in weight and volume percentages: 2.0% glucose, 0.1% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 20% potato juice, and 2.0% agar.

[0112] (2) Shake flask seed culture:

[0113] Put 20ml of seed culture medium in a 50ml triangular flask, sterilize it, connect it to the slant mother seed after cooling, shake it, and co-cultivate it for 4 days;

[0114] Seed medium formula: 3% corn flour, 1% starch, 1% bran, 1% yeast, 0.1% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 0.005% each of vitamin B1 and vitamin B2.

[0115] The conditions for seed culture in shake flasks are as follows: at 25° C., the rotation speed of the shaker is 150 r / min, the volume of liquid in the ...

Embodiment 3

[0126] (1) Activation of slant strains:

[0127] The strains of Pleurotus ostreatus were grafted onto the slant of potato juice comprehensive medium, and cultured at a constant temperature of 24°C for 10 days.

[0128] The selected potato comprehensive medium contains the following substances in weight and volume percentages: 2.0% glucose, 0.1% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 20% potato juice, and 2.0% agar.

[0129] (2) Shake flask seed culture:

[0130] Put 20ml of seed culture medium in a 50ml triangular flask, sterilize it, connect it to the slant mother seed after cooling, shake it, and co-cultivate it for 6 days;

[0131] Seed medium formula: 3% corn flour, 1% starch, 1% bran, 1% yeast, 0.1% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 0.005% each of vitamin B1 and vitamin B2.

[0132] The conditions for seed cultivation in shake flasks are as follows: at 25° C., the rotation speed of the shaker is 150 r / min, the volume of liquid in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com