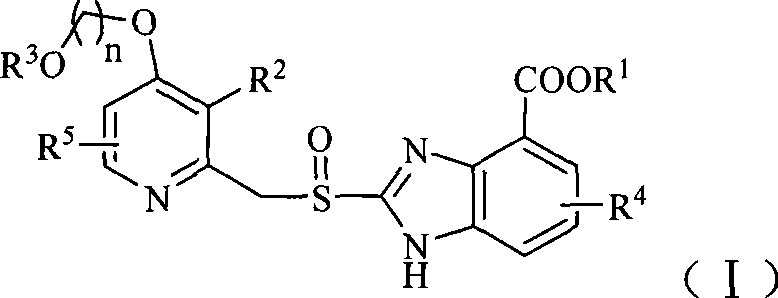

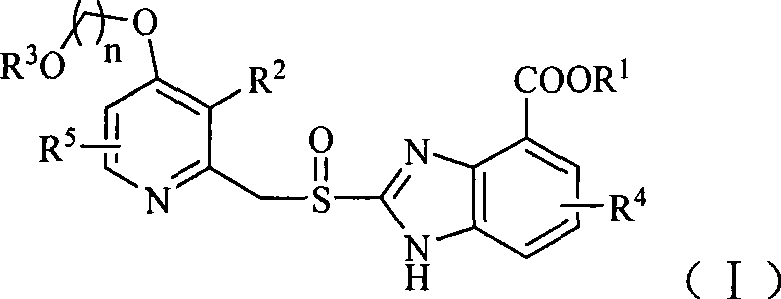

Benzimidazole derivative containing alkoxy substituted pyridine

A technology of alkoxy and alkyl, which is applied in the application fields of benzimidazole derivatives and drugs, and can solve the problems of affecting drug efficacy and pharmacokinetic parameters, insufficient drug efficacy, and large individual differences in pharmacokinetics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

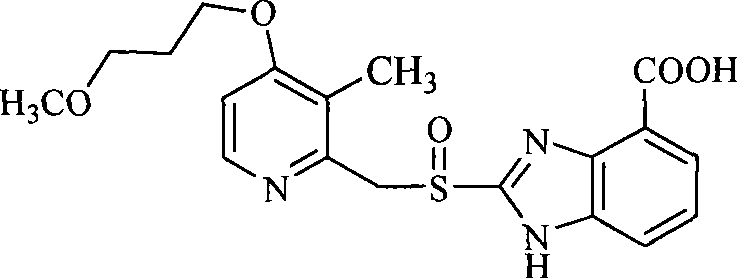

Embodiment 1

[0102] Example 1 Preparation of 2-mercapto-4-methoxycarbonyl-benzimidazole

[0103] Put 10g (60mmol) of 2,3-diamino-benzoic acid methyl ester into the reaction flask, add 200ml of ethyl acetate, then add 12.8g (80mmol) of potassium ethoxysulfonate, and heat to reflux at 80°C for 4h. After the reaction was completed, cool to room temperature, pour the reaction solution into 200ml of ice water, stir evenly, adjust the pH to 3-4 with 4N hydrochloric acid, precipitate a solid, filter, wash with water until neutral, and vacuum-dry the filter cake to obtain 9.1g of the product. Rate: 73.2%.

Embodiment 2

[0104] Example 2 Preparation of 4-(3-methoxypropoxy)-2,3-dimethyl-N-pyridine oxide

[0105] Add 16.8g (100mmol) of 4-(3-methoxypropoxy)-2,3-dimethyl-N-pyridine oxide, 100ml of 1,3-propylene glycol monomethyl ether, powder Potassium carbonate 20g, heated and stirred under reflux for 12h, stopped the reaction, cooled to room temperature, filtered, the filtrate was concentrated under reduced pressure to recover excess 1,3-propanediol monomethyl ether, and the oily substance 4-(3-methoxypropoxy) - 11.2 g of 2,3-dimethyl-N-pyridine oxide, yield: 53.2%, directly put into the next step for reaction.

Embodiment 3

[0106] Example 3 Preparation of 4-(3-methoxypropoxy)-2-hydroxymethyl-3-methyl-pyridine

[0107] Add 21.1g (100mol) of 4-(3-methoxypropoxy)-2,3-dimethyl-N-pyridine oxide and 200ml acetic anhydride to a dry reaction flask, heat up to 60°C and stir for reaction 1 After 2 hours, the acetic anhydride was distilled off under reduced pressure, 150ml of 2N sodium hydroxide solution was added to the residue, stirred and reacted at 40°C for 4 hours, extracted with chloroform (100ml×3), dried and concentrated to obtain 14.8g of oil, yield 70.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com