Capacity increasing modifying method for polyphenylene oxide / nylon 6 alloy

A technology of compatibilization and modification, polyphenylene ether, which is applied in the field of compatibilization and modification of polyphenylene ether/nylon 6 alloy, can solve the problems of poor mechanical properties and impact resistance, and improve compatibility and system compatibility. properties, and the effect of reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1—3

[0024] 1. Nylon 6 and styrene-maleic anhydride copolymer were pre-dried under vacuum at 80°C for 12 hours;

[0025] 2. After mixing 50 parts of styrene-maleic anhydride copolymer and 50 parts of nylon 6, put them into a twin-screw extruder for extrusion and granulation. The screw temperature is 230-250 °C and the screw speed is 150 rpm. Continuous extrusion granulation 1 time (embodiment 1), 2 times (embodiment 2), 4 times (embodiment 3), obtain the blend of nylon 6 / styrene-maleic anhydride copolymer;

[0026] 3. Add the blend of nylon 6, polyphenylene ether and nylon 6 / styrene-maleic anhydride copolymer into the twin-screw extruder according to the ratio in Table 1 for extrusion and granulation, and the screw temperature is 240~ 250°C, screw speed 100-170 rpm, a compatibilized polyphenylene ether / nylon 6 alloy is obtained.

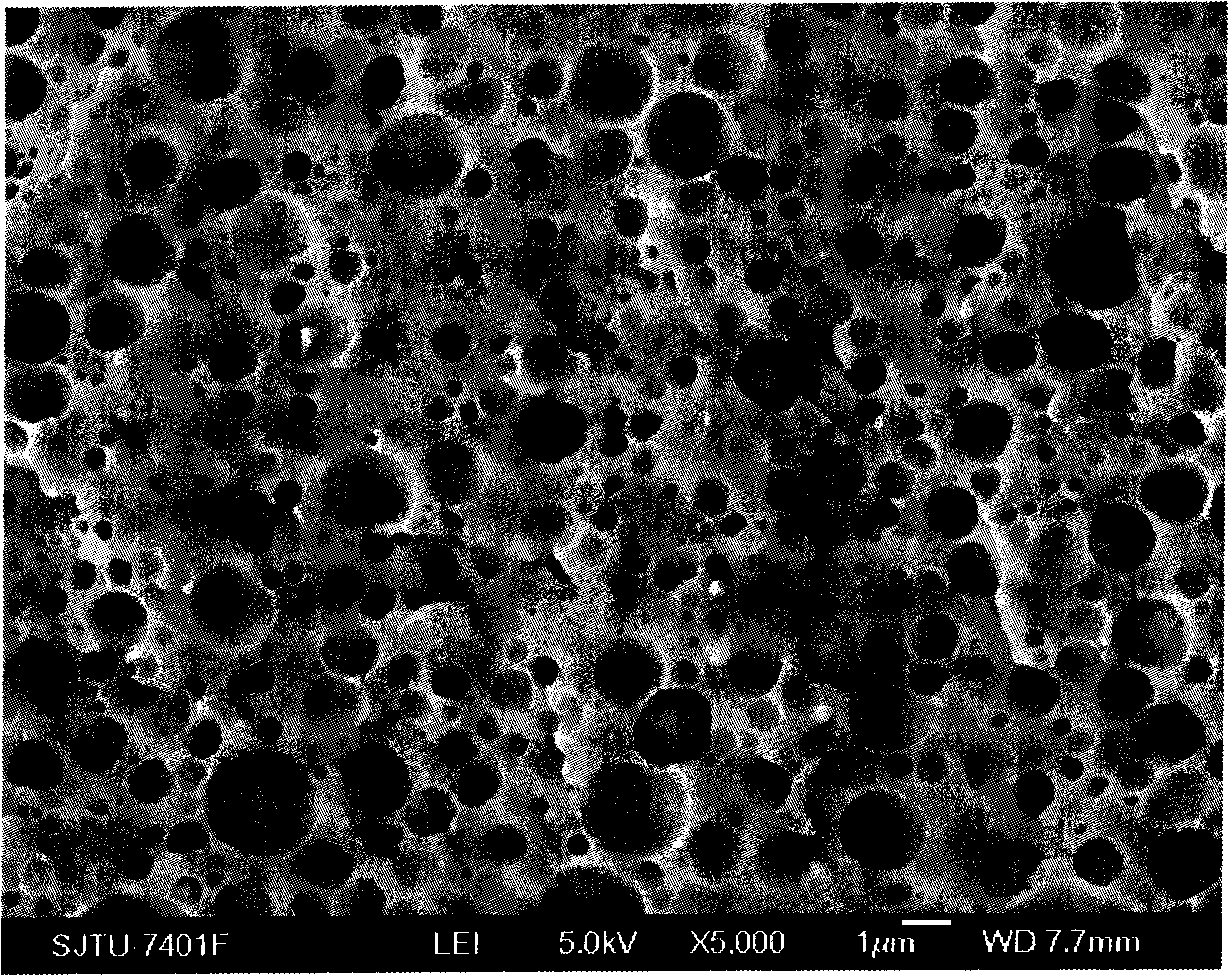

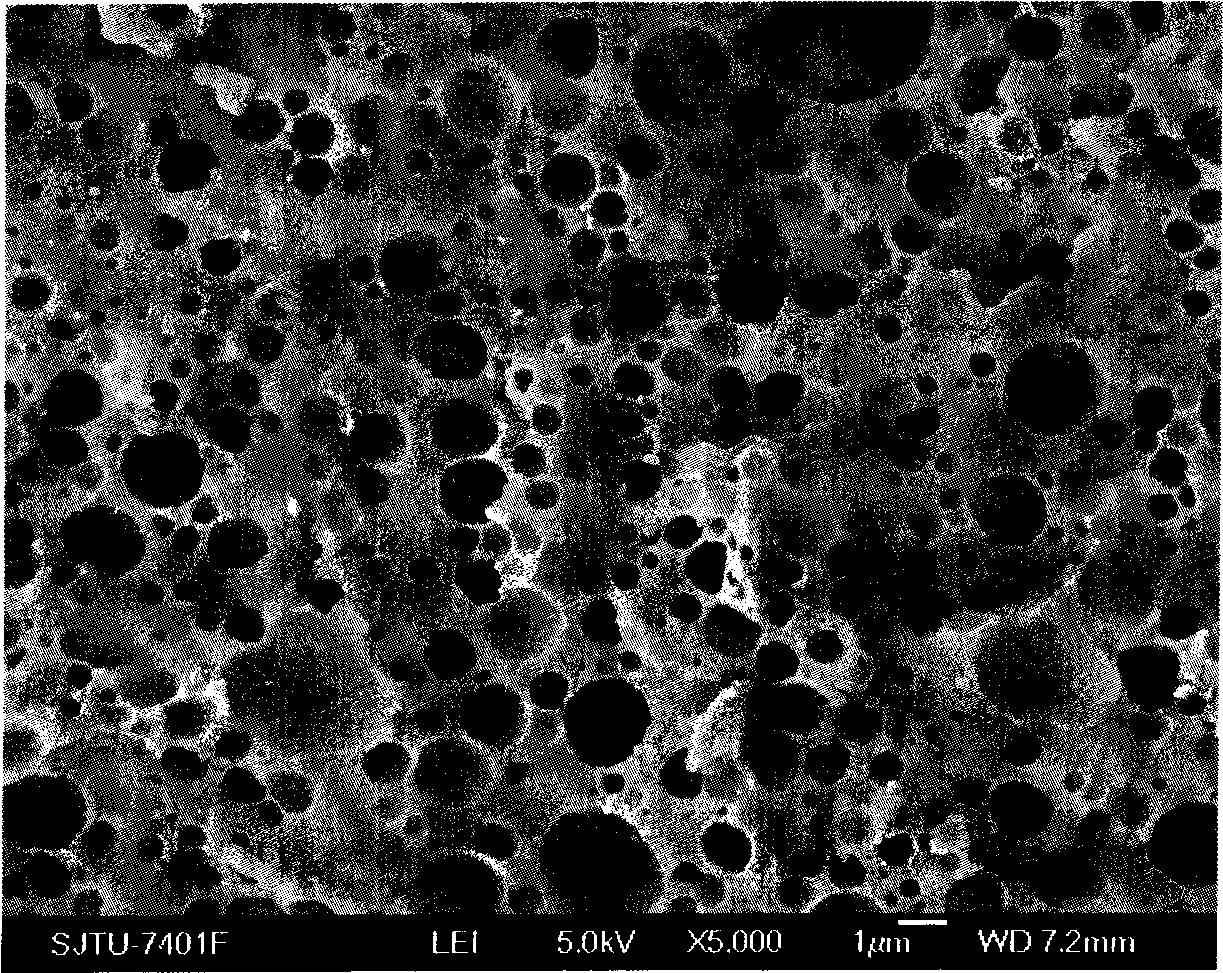

[0027] The performance test of the polyphenylene ether / nylon 6 alloy obtained in Examples 1-3 is shown in Table-1, figure 1It is the liquid nitrogen em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com