Membrane-electrode assembly, electrolytic cell employing the same, electrolytic-water sprayer, and method of sterilization

A membrane electrode assembly, electrolytic cell technology, applied in electrolytic assemblies, chemical instruments and methods, disinfection and other directions, can solve the problems of difficulty in obtaining size reduction, poor electrolyte operation performance, wide application, difficulty in ozonizing water, etc., to improve sterilization. Active, novel bactericidal effect, freshness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

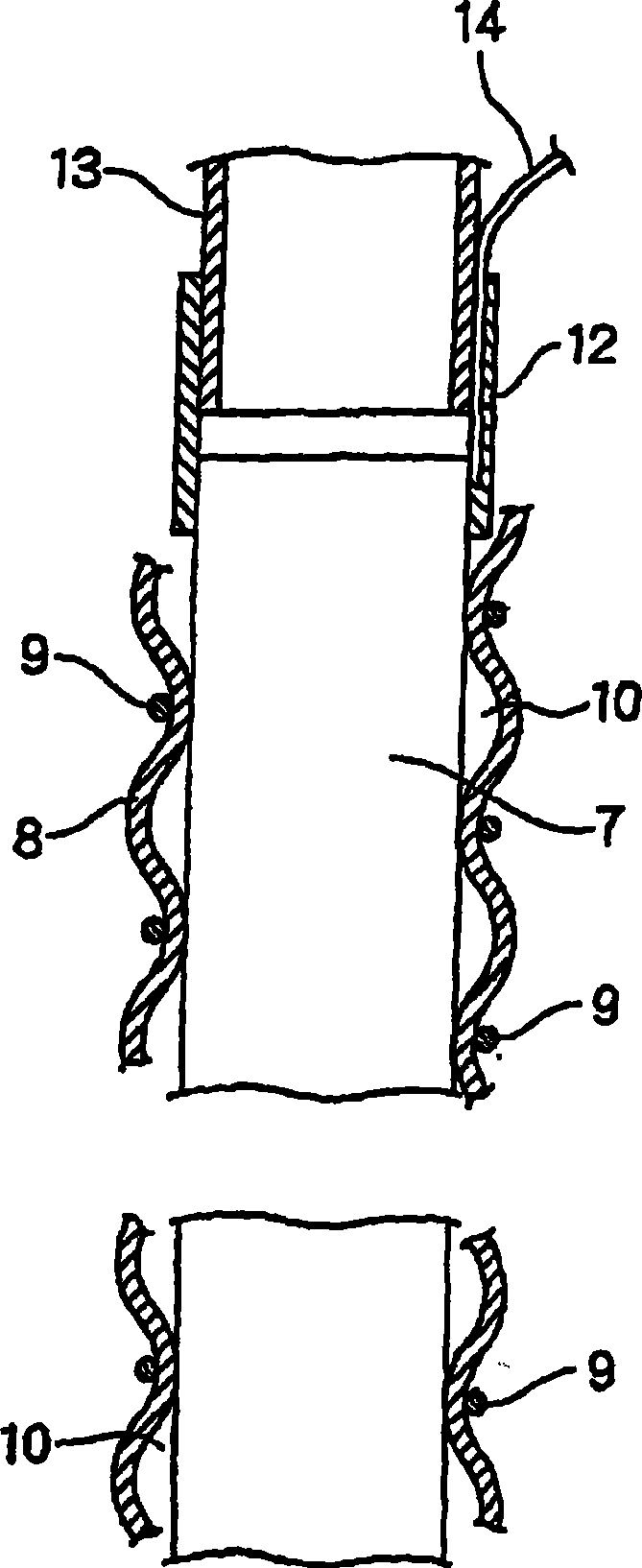

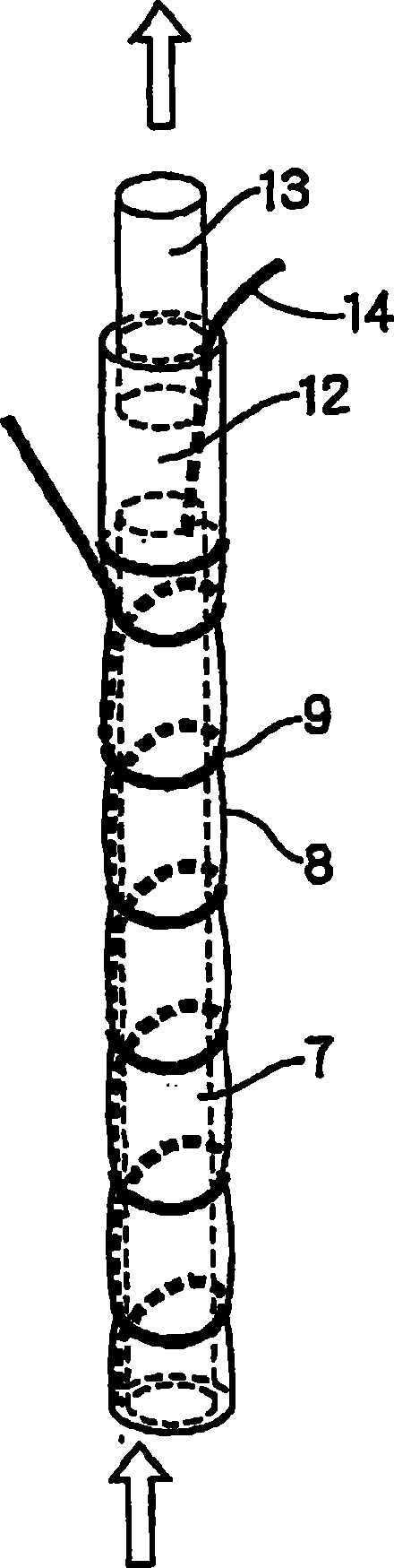

[0222] A rod (diameter, 2 mm) made of niobium, on which a conductive diamond catalyst (doped agent boron concentration, 2,500ppm). On the separator, a commercial platinum wire (diameter, 0.4 mm) was helically wound as the cathode to obtain an anode-membrane-cathode assembly. The winding pitch is 4mm. Tubes (diameter, 4 mm) were bonded to the upper and lower parts of the assembly, and feed lines from a DC power source were connected to the respective electrodes to obtain an electrolysis cell. Pure water flows upward through the anode chamber at a rate of 40cc / min. Currents of 0.5A and 1A were made to flow individually. As a result, in these operations, the cell voltages were 13 V and 19 V, respectively, the ozonized water concentrations were 8 ppm and 21 ppm, and the ozone generation efficiencies were 13% and 12%, respectively. The water temperature at the outlet is about 30°C.

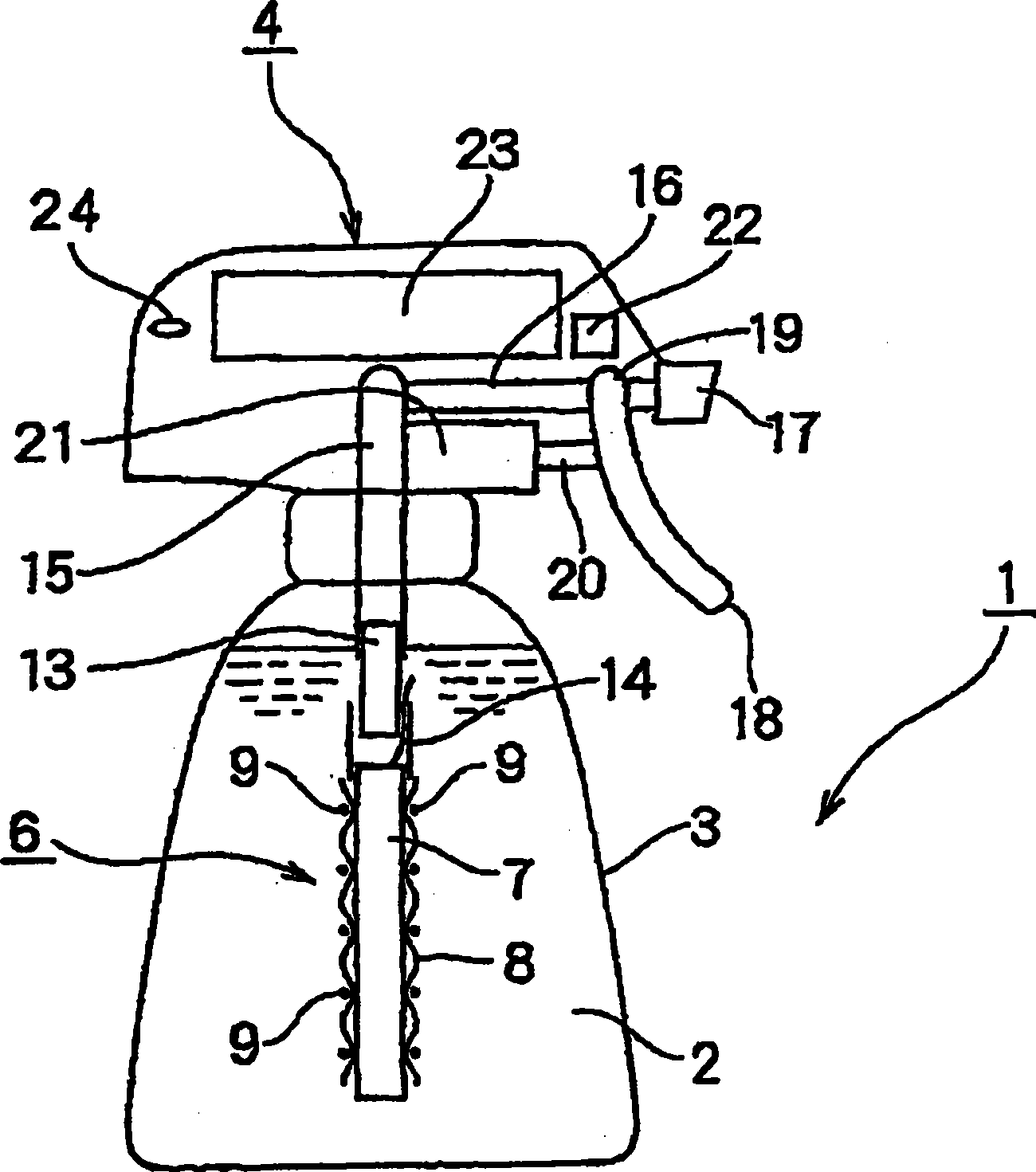

[0223] exist figure 1 In the trigger type injector shown, the electrolyzer is connected to a ...

example 2

[0228] Those parts of the membrane in the assembly of example 1, which constitute the two openings of the anode chamber, were fixed to a tube with a diameter of 4 mm. The resulting part was arranged in a second tube having an inner diameter of 5 mm to form a cathode chamber between the second tube and the membrane. Connect the feed wire terminal for the wire cathode to the cathode in the second tube. A 2 g / L aqueous solution of sodium chloride was fed to the anode chamber at a rate of 40 cc / min, and water was also fed to the cathode chamber in the same manner. Make a current of 1A flow. As a result, alkaline water containing hydrogen gas and having a pH of 11 and acidic water containing hypochlorite ions in an amount of 40 ppm can be simultaneously obtained.

example 3

[0230] The same test as Example 2 was performed except that tap water was fed to the anode and cathode chambers. As a result, ozonized water was produced at 0.5 A with a concentration of 4.5 ppm (current efficiency, 7.3%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com