Process for production of oxymethylene copolymers

A technology of oxymethylene copolymerization and polymerization reaction, which is applied in the field of preparation of oxymethylene copolymers, and can solve the problems of reduced toughness, decreased productivity, low melt index and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

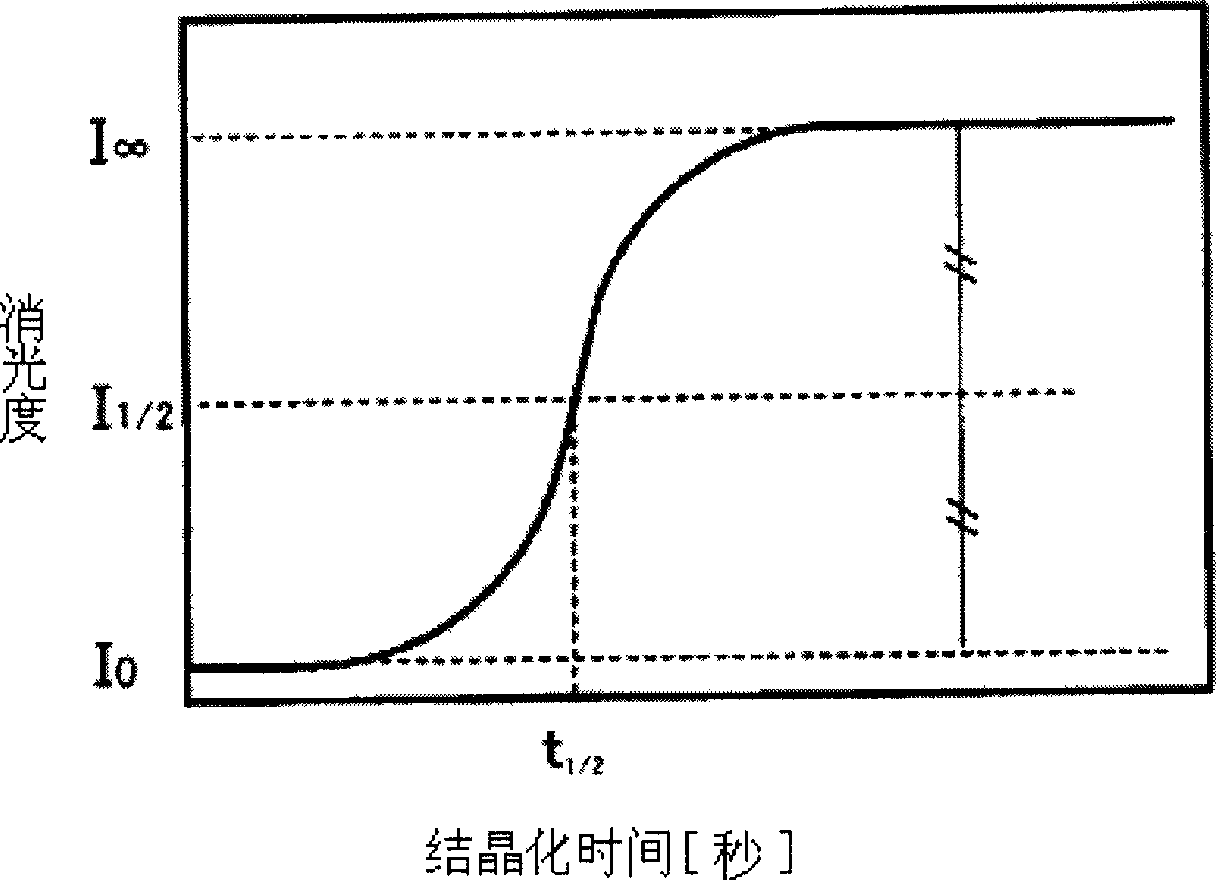

Image

Examples

preparation example Construction

[0020] In the preparation method of the oxymethylene copolymer of the present invention, comprise utilizing cationic polymerization catalyst to trioxane (A component) and the cyclic ether and / or cyclic formal (B component) that have at least one carbon-carbon bond in the ring structure ) A step of continuously polymerizing in a polymerization reaction system (polymerization step).

[0021] As a polymerization method for obtaining an oxymethylene copolymer, it is preferable to apply a bulk polymerization method that does not use a solvent substantially. This so-called bulk polymerization method refers to a polymerization method that utilizes monomers in a molten state. As the polymerization proceeds, the polymer crystallizes out in the monomer mixture, and soon the whole system becomes blocky and powdery to obtain a solid. shaped aggregates. This polymerization is preferably carried out under an oxygen-free condition, more preferably under a nitrogen atmosphere.

[0022] Cati...

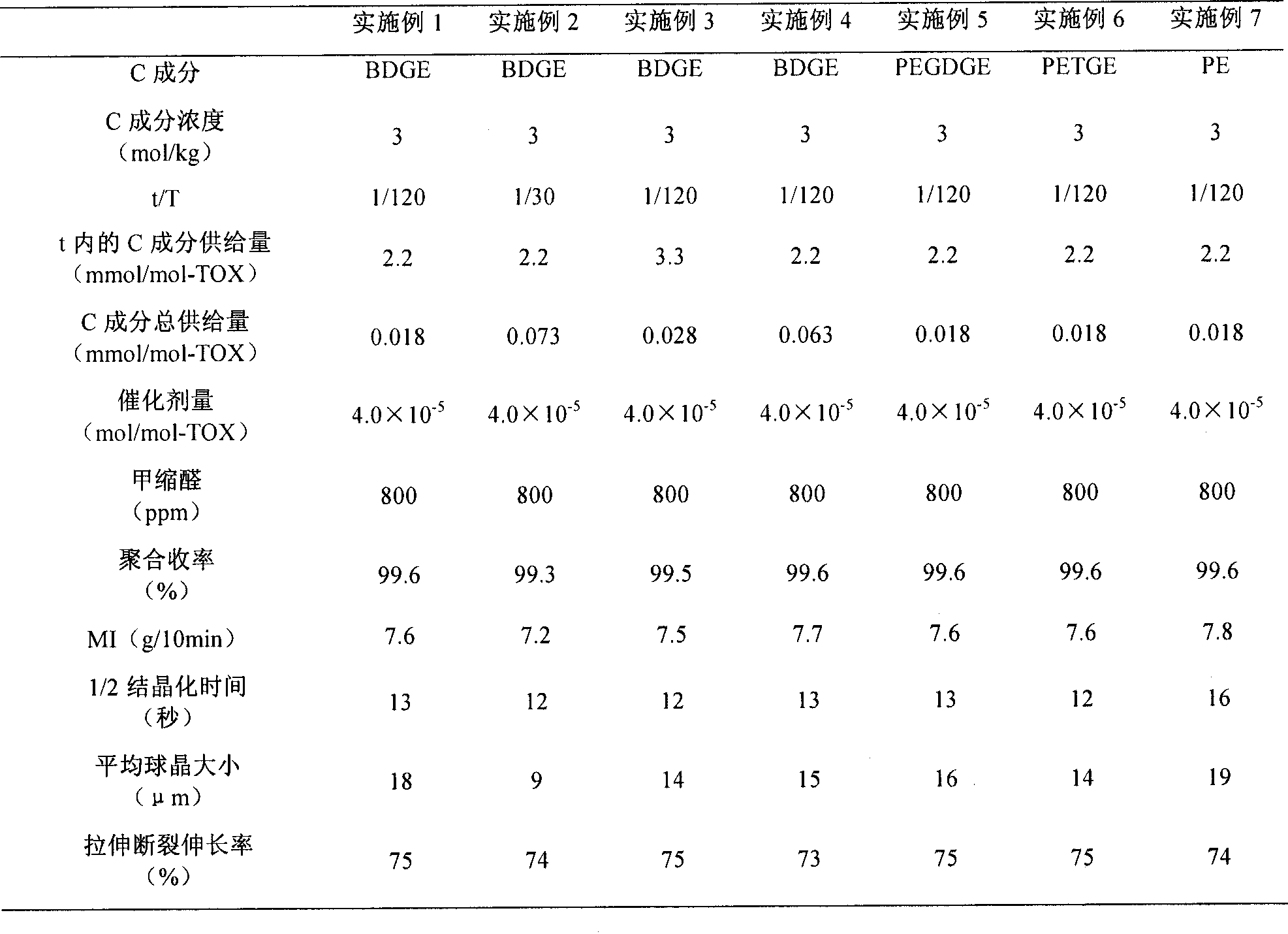

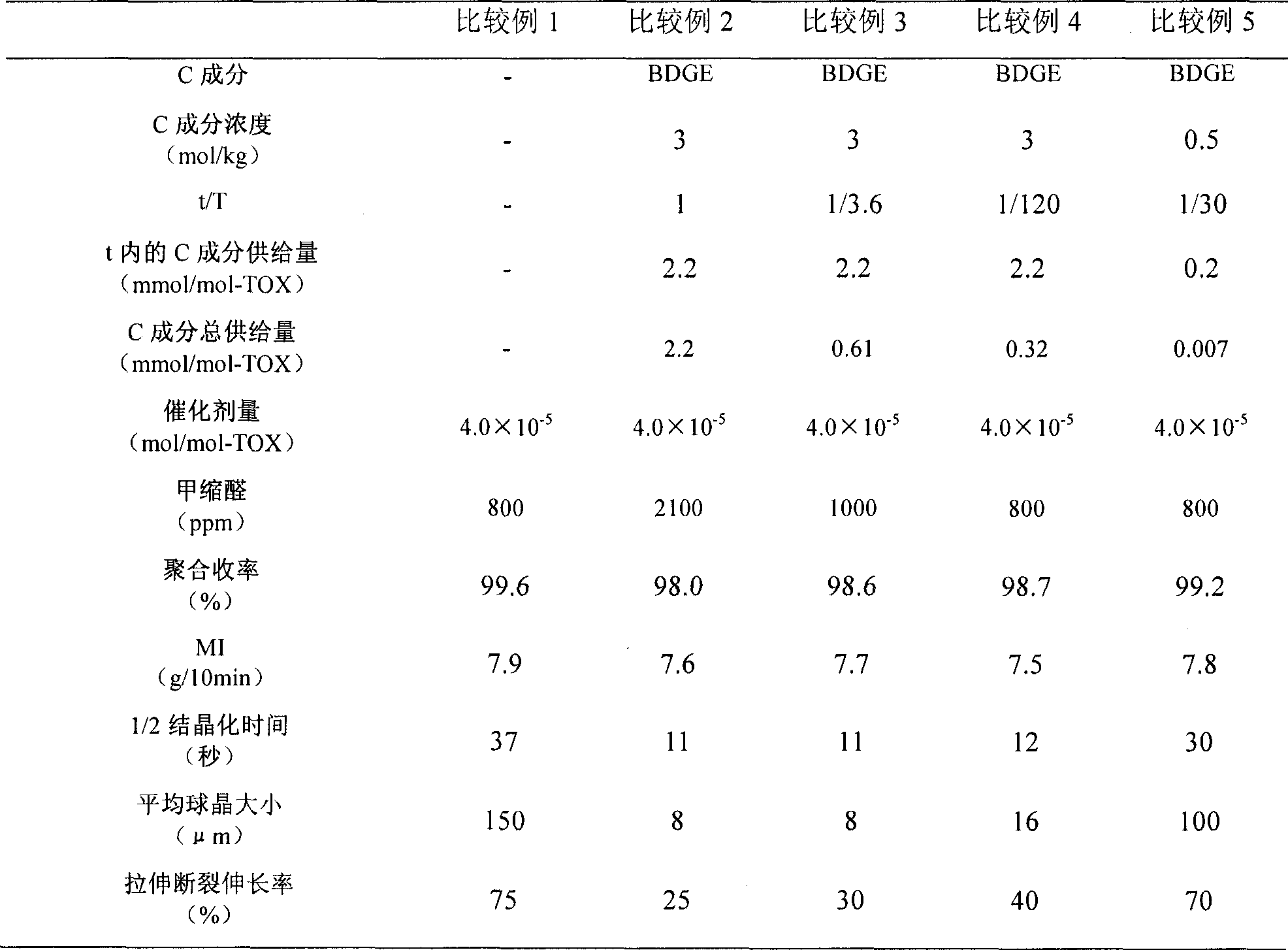

Embodiment 1~7、 comparative example 1~5

[0066] An oxymethylene copolymer was produced using, as a continuous reaction apparatus, an apparatus obtained by serially connecting two of the above-mentioned continuous reaction machine and the terminator mixer in order from the raw material supply side.

[0067] Under the conditions described in the following Table 1 and Table 2, intermittently to the mixed flow of 90.0 kg / hr of trioxane (A component) and 3.8 kg / hr of 1,3-dioxolane (B component) Supply C component, further, supply the benzene solution (25 mass %) of methylal, the benzene solution (preparation concentration: 0.3mol / kg), immediately introduced into the first continuous reactor for continuous polymerization (block polymerization).

[0068] However, the supply of the C component in Example 4 was carried out so that the minimum supply rate of the C component was 0.045 mmol per 1 mol of trioxane, and the maximum supply rate was 2.2 mmol per 1 mol of trioxane. In Comparative Example 4, the C component was suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com