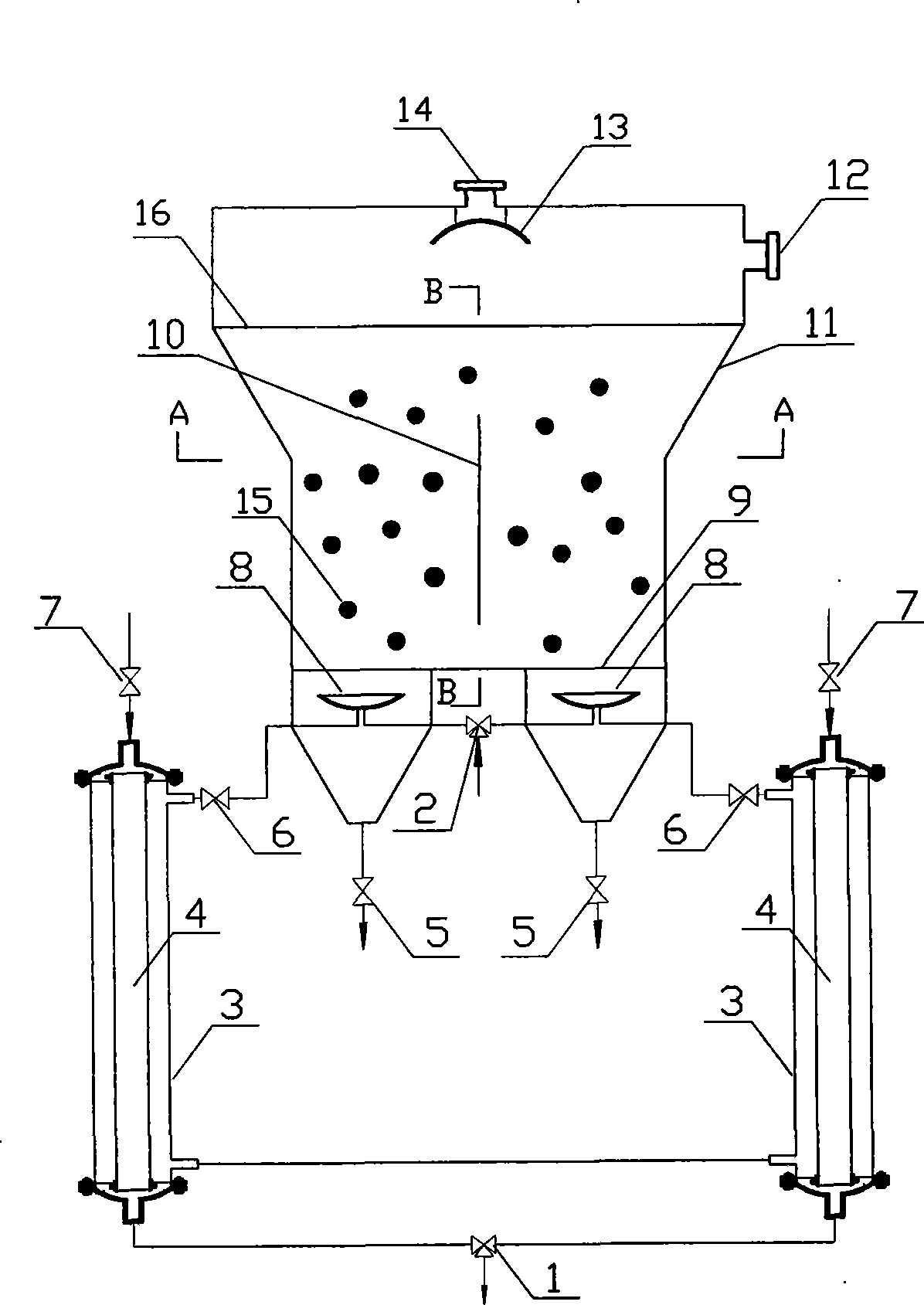

Double-circulating ceramic membrane bioreactor

A bioreactor, bioreactor technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Membrane fouling and operating energy consumption, etc., to achieve the effect of strengthening biochemical effects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

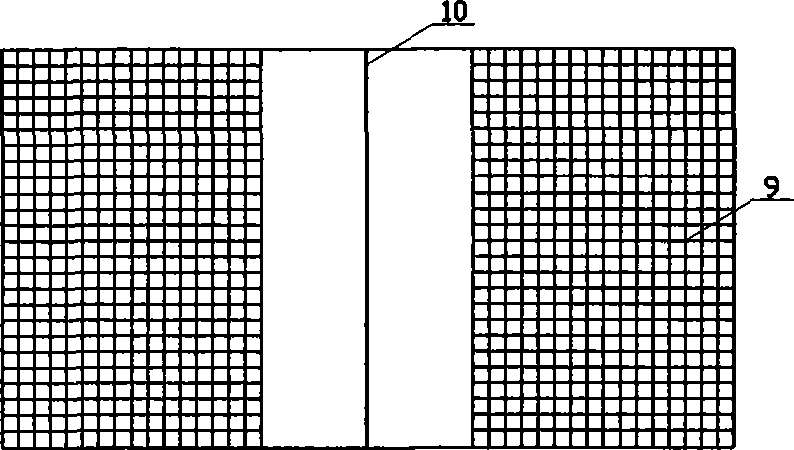

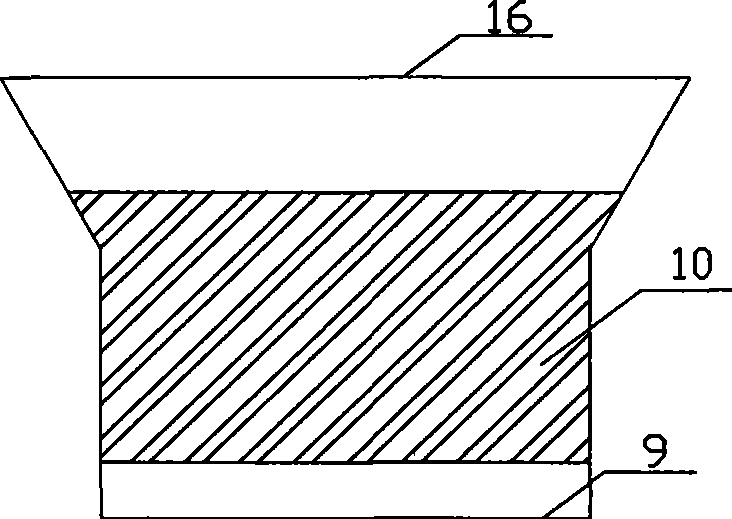

[0025]Example: domestic sewage treatment in a residential area

[0026] Use the above-mentioned device to treat domestic sewage and COD of sewage in a community cr is 250~350mg / l, ammonia nitrogen is 40~60mg / l, and the effective reaction volume of biological reaction pool 11 of this device is 0.2m 3 Control the temperature of the bioreactor to about 30°C. The filter membrane element is a single-channel ceramic membrane tube with a tube length of 0.8m, an inner diameter of 9mm, an outer diameter of 13mm, and a membrane pore size of 0.8μm. Granular activated carbon is used as a biological filler, and the specification is 10mm×10mm×10mm. The suction negative pressure is stable at 0.08MPa, and the backwash gas velocity (corrected) is stable at 6L / min. The backwash aeration and suction filtration operations of the two membrane modules are switched every hour, and the effluent water quality indicators are monitored every 20 minutes. The monitoring results show that: effluent COD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com