Method and device for continuous fermentation and separation coupling of biomacromolecule product

A biomacromolecule and separation device technology, which is applied in the field of continuous fermentation and separation coupling of biomacromolecule products, can solve the difficulty of fermentation liquid flow, mixing, dissolved oxygen, difficulty in increasing the content of products in the fermentation liquid, and macromolecular product Molecular weight is difficult to control and other problems, to achieve the effect of improving equipment utilization, improving raw material conversion rate, improving process continuity and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

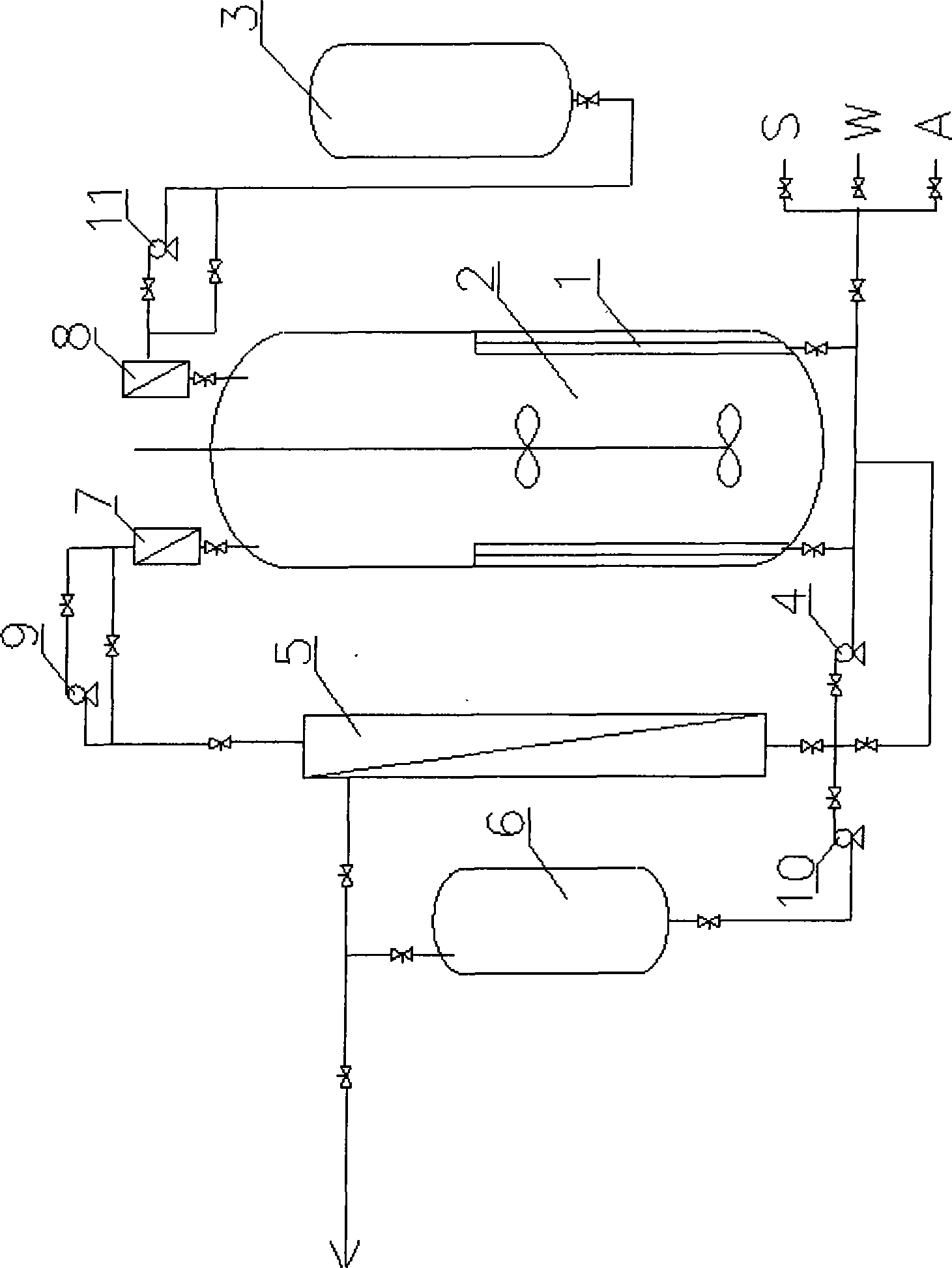

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

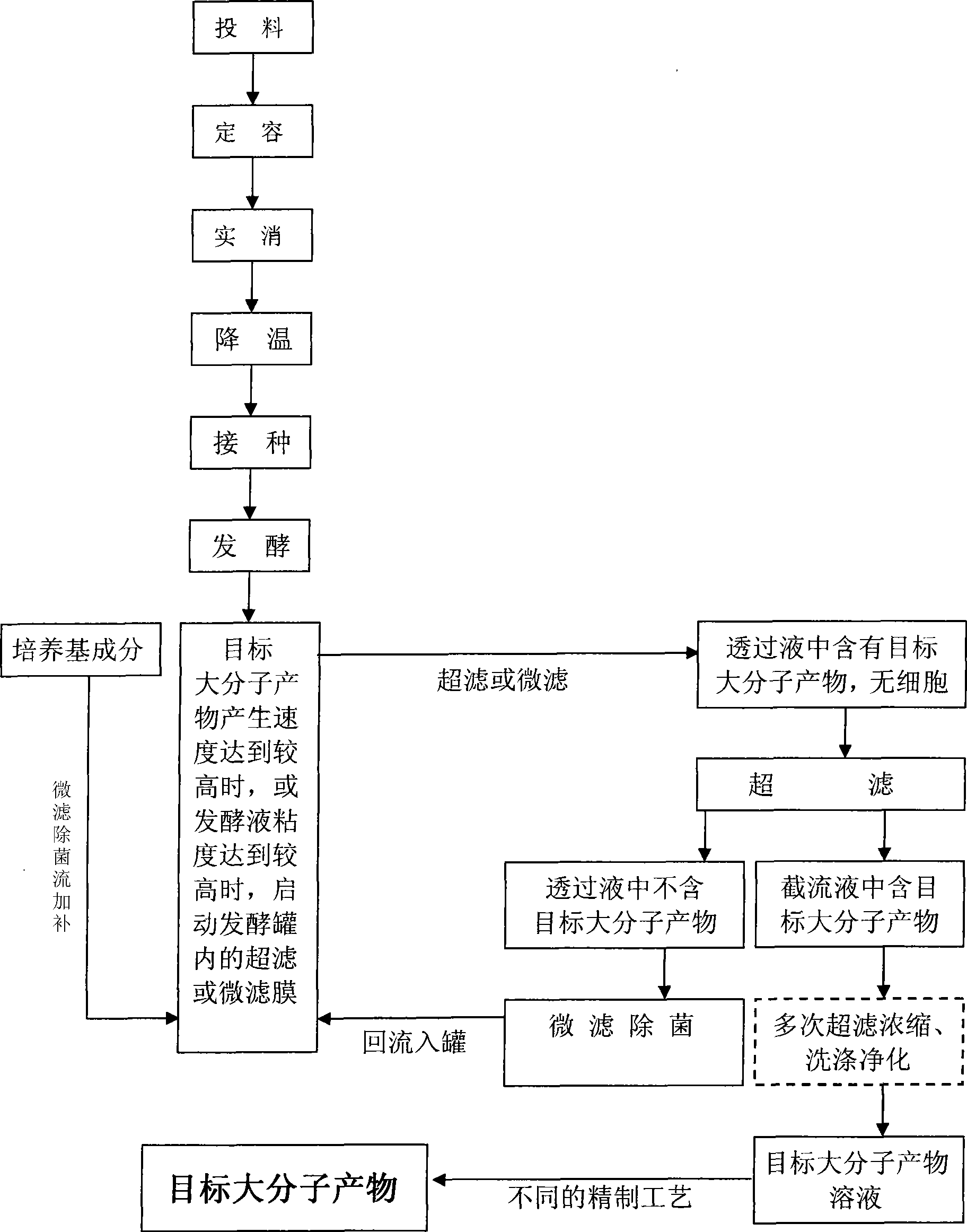

[0022] see figure 2 Flowchart of the method for coupling continuous fermentation and separation of biological macromolecular products. Firstly, put the fermentation raw materials into the fermenter 2 that has been decontaminated, and add water to the required volume.

[0023] Then feed steam into the fermenter 2 to carry out actual sterilization of the culture medium and the fermenter 2; simultaneously use steam to the ultrafiltration membrane or the microfiltration membrane 1, the microfiltration membrane module 7, the microfiltration membrane module 8, and the ultrafiltration membrane Components 5, storage tank 6, etc. and their connected pipelines, valves, pumps, etc. are sterilized. After sterilization, lower the temperature of the fermenter 2 to an appropriate temperature, insert strains into the fermenter 2 according to an appropriate inoculum amount,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com