Method for synthesizing polymeric ferric sulfate by microbial catalysis

A technology of polymerizing ferric sulfate and microorganisms, which is applied in the field of environmental engineering, can solve the problems of high equipment and production conditions, large acid input, etc., and achieve the effect of increasing the basicity, reducing the amount of addition, and improving the flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

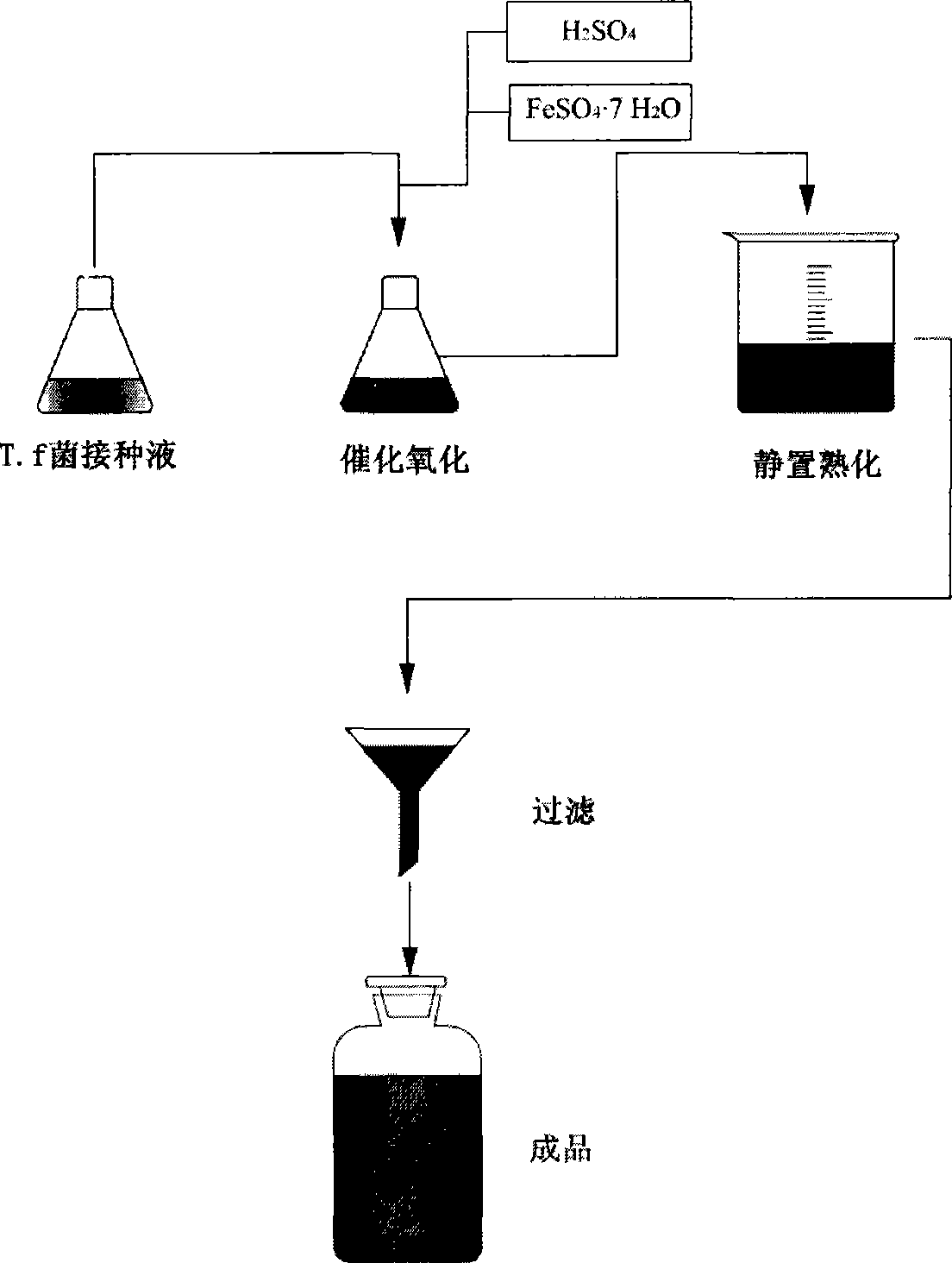

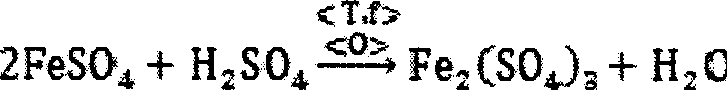

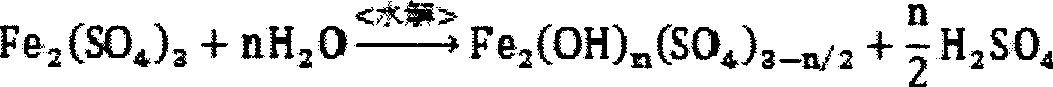

[0035] Example 1 Catalytic synthesis of polyferric sulfate by microbial method

[0036] Weigh analytically pure FeSO 4· 7H 2 O300g is placed in a 500mL conical flask, add 200mL of deionized water, measure 100mL of Thiobacillus ferrooxidans inoculum with a graduated cylinder and put it in the conical flask, and adjust the pH of the system to 1.4 with sulfuric acid, seal the bottle mouth with gauze, and place at 28°C Constant temperature shaking incubator at 180r.min -1 Shake culture under the conditions for 60 hours, take it out, put it in a cool and dry place and let it stand for 3 weeks, then filter to remove the insoluble matter, and measure the indicators of the product. After analysis, the basicity is 14.5%, and the property parameters of this product are as follows:

[0037] project standard value Measured value of this product Density, g / cm 3 (20°C) — 1.285 pH (1% aqueous solution) 2.0—3.0 2.2 Total iron content, %≥ 11.0 11.27 R...

Embodiment 2

[0039] Example 2 Catalytic synthesis of polyferric sulfate by microbial method

[0040] Weigh analytically pure FeSO 4· 7H 2 O 35kg is placed in the reactor (full-automatic microbial fermentation tank) that has added 20L deionized water, add Thiobacillus ferrooxidans inoculum 15L, and after adjusting system pH=1.4 with sulfuric acid, open the reactor, the temperature is set to 28 ℃ , and ventilation and stirring at the same time, the reaction 60h. After taking it out, put it in a cool and dry place to stand and mature for 4 weeks, then filter to remove the insoluble matter. The properties and parameters of the product are as follows.

[0041] project standard value Measured value of this product Density, g / cm 3 (20°C) — 1.281 pH (1% aqueous solution) 2.0—3.0 2.15 Total iron content, %≥ 11.0 11.25 Reduced iron content, %≤ 0.1 — Basicity, %≥ 9.0 14.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com