Alloying technique for semiconductor chip Au-Si solder

A technology of alloy technology and semiconductor, applied in the direction of metal material coating technology, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of affecting output and reducing the efficiency of bonding chips, and achieve improved yield and short processing time , Fast heating and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

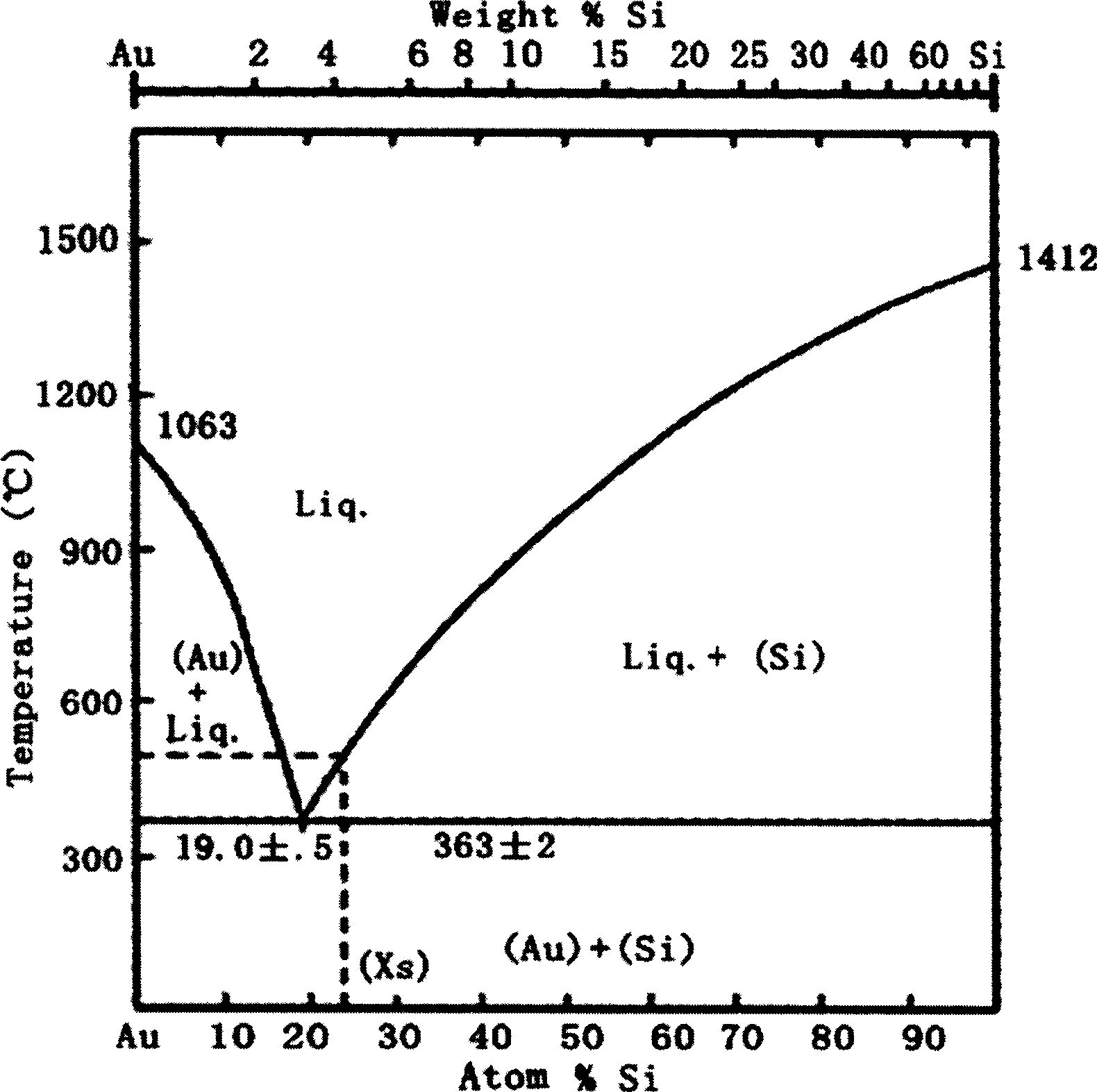

[0028] The above-mentioned silicon wafers were alloyed in a rapid annealing furnace at a temperature of 530°C for 30 seconds. After alloying, the silicon wafers were observed with a metallographic microscope. The pattern on the back side is completely different, and the pattern observed under the 5 times metallographic microscope on the back side of the silicon wafer is # shape (attached Figure 4 ), under a 10x metallographic microscope, only the color of silicon can be seen on the #-shaped lines (attached Figure 5 ), the color of flake silicon will not appear on the whole piece.

[0029] The gold-silicon solder after the alloy is used for trial welding, and the silicon residue can basically reach more than 95%; after the eutectic chip is bonded, the saturation pressure drop and thermal resistance are reduced by about 10%, and the repeatability is very good.

[0030] As can be seen from the above comparative examples and examples, the rapid annealing furnace alloy can thoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com