Manganese dioxide doped hafnium oxide ceramic material and method of producing the same

A technology of manganese dioxide and ceramic materials, applied in the field of hafnium oxide-based ceramics, can solve the problems of low HfO2 content, not widely used, and few researches, and achieve the effects of easy control of reaction conditions, sufficient reaction, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

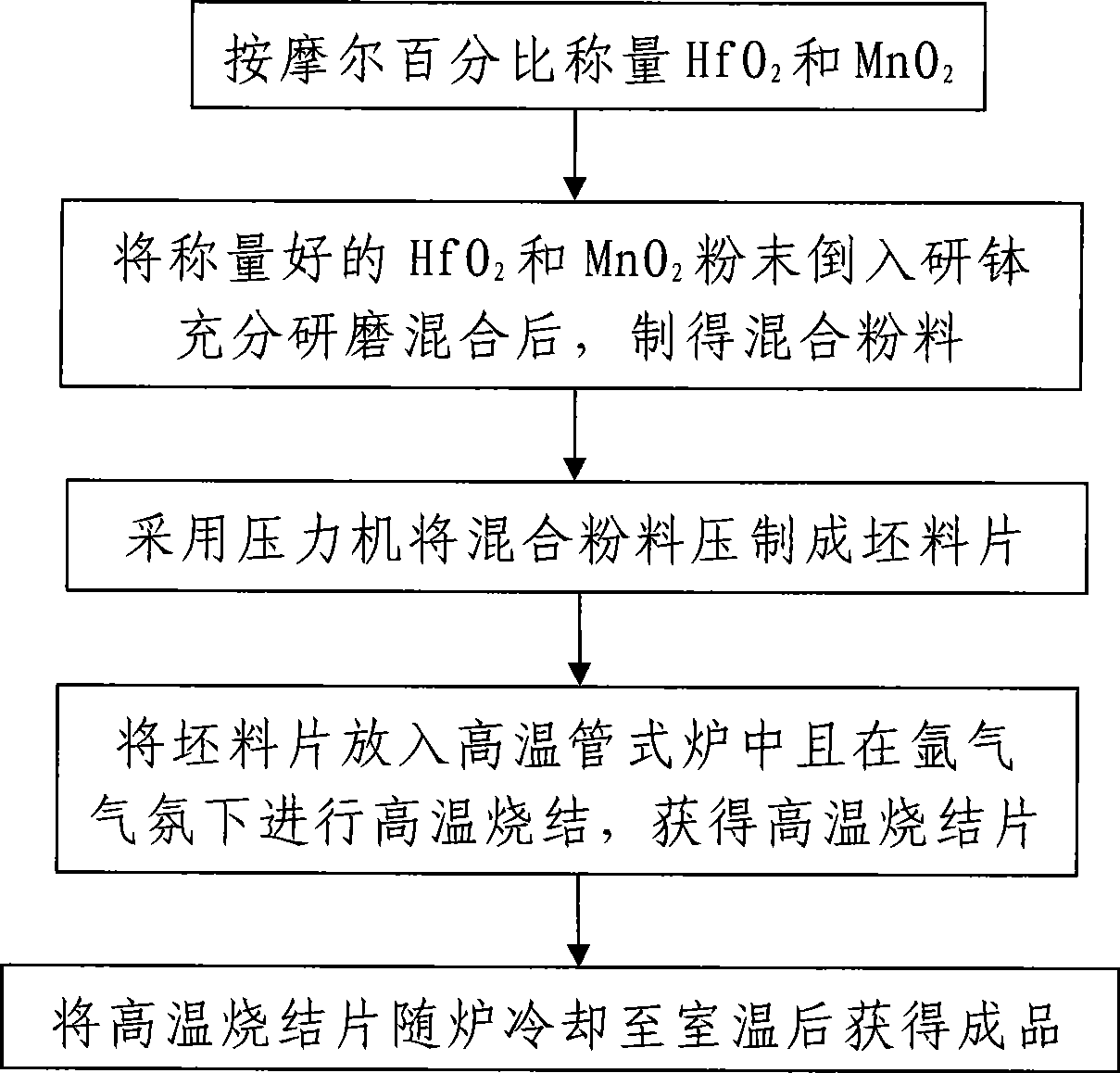

[0016] Such as figure 1 As shown, the tetragonal hafnium oxide ceramic material doped with manganese dioxide according to the present invention is composed of 20% to 50% dopant and 50% to 80% hafnium oxide HfO 2 Composition, the dopant is transition metal oxide manganese dioxide MnO 2 . In this example, hafnium oxide HfO 2 and manganese dioxide MnO 2 The molar percentages are 75% and 25%, respectively.

[0017] The method for preparing the tetragonal hafnium oxide ceramic material doped with manganese dioxide includes the following steps:

[0018] Step 1. Weigh hafnium oxide HfO according to mole percentage 2 and manganese dioxide MnO 2 .

[0019] In this example, due to hafnium oxide HfO 2 and manganese dioxide MnO 2 The molar percentages are 75% and 25%, then pure HfO will be analyzed 2 and MnO 2 According to Hf 0.75 mn 0.25 o 2-δ The stoichiometric ratio was weighed.

[0020] Step 2, the weighed hafnium oxide HfO 2 and manganese dioxide MnO 2 All the powder...

Embodiment 2

[0029] In this example, the difference from Example 1 is that in the tetragonal hafnium oxide ceramic material doped with manganese dioxide to be prepared, hafnium oxide HfO 2 and manganese dioxide MnO 2 The molar percentages are 70% and 30%, respectively.

[0030] Correspondingly, when preparing the tetragonal hafnium oxide ceramic material doped with manganese dioxide, weigh hafnium oxide HfO 2 and manganese dioxide MnO 2 , due to hafnium oxide HfO 2 and manganese dioxide MnO 2 The mole percentage of 70% and 30%, then the pure HfO will be analyzed 2 and MnO 2 According to Hf 0.7 mn 0.3 o 2-δ The stoichiometric ratio is weighed; in step 3, use a press to press the mixed powder obtained after mixing and grinding into a rectangular green sheet with a size of 50mm×5mm×3mm under a pressure of 10MPa; in step 4, press into When the green sheet is put into a high-temperature tube furnace and sintered at a high temperature under an argon atmosphere, the heating rate of the h...

Embodiment 3

[0032] In this example, the difference from Example 1 is that in the tetragonal hafnium oxide ceramic material doped with manganese dioxide to be prepared, hafnium oxide HfO 2 and manganese dioxide MnO 2 The molar percentages are 50% and 50%, respectively.

[0033] Correspondingly, when preparing the tetragonal hafnium oxide ceramic material doped with manganese dioxide, weigh hafnium oxide HfO 2 and manganese dioxide MnO 2 , due to hafnium oxide HfO 2 and manganese dioxide MnO 2The mole percentage of 50% and 50%, then pure HfO will be analyzed 2 and MnO 2 According to Hf 0.5 mn 0.5 o 2-δ The stoichiometric ratio is weighed; in step 3, a press is used to compress the mixed powder obtained after mixing and grinding into a size of circular green sheet; in step 4, when the pressed green sheet is put into a high-temperature tube furnace and sintered at a high temperature under an argon atmosphere, the heating rate of the high-temperature tube furnace is 200° C. / h, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com