Method for separating and extracting fibrillar structure body in natural keratin fiber with reducing solvent

A technology of keratin fibers and structures, applied in the field of natural fiber processing, can solve problems such as refractory degradation and environmental pollution, and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 5g of wool after loosening and cleaning are washed with acetone, dried and cut into 5mm pieces, which are immersed in 250ml of a solution (pH=6.5) containing sodium metabisulfite and urea, wherein the solution is prepared by adding sodium metabisulfite Add it to 8M urea aqueous solution, the mass concentration of sodium metabisulfite is 7%, stir the mixture at 80°C for 5h, and the stirrer rotates at a speed of 300r / min.

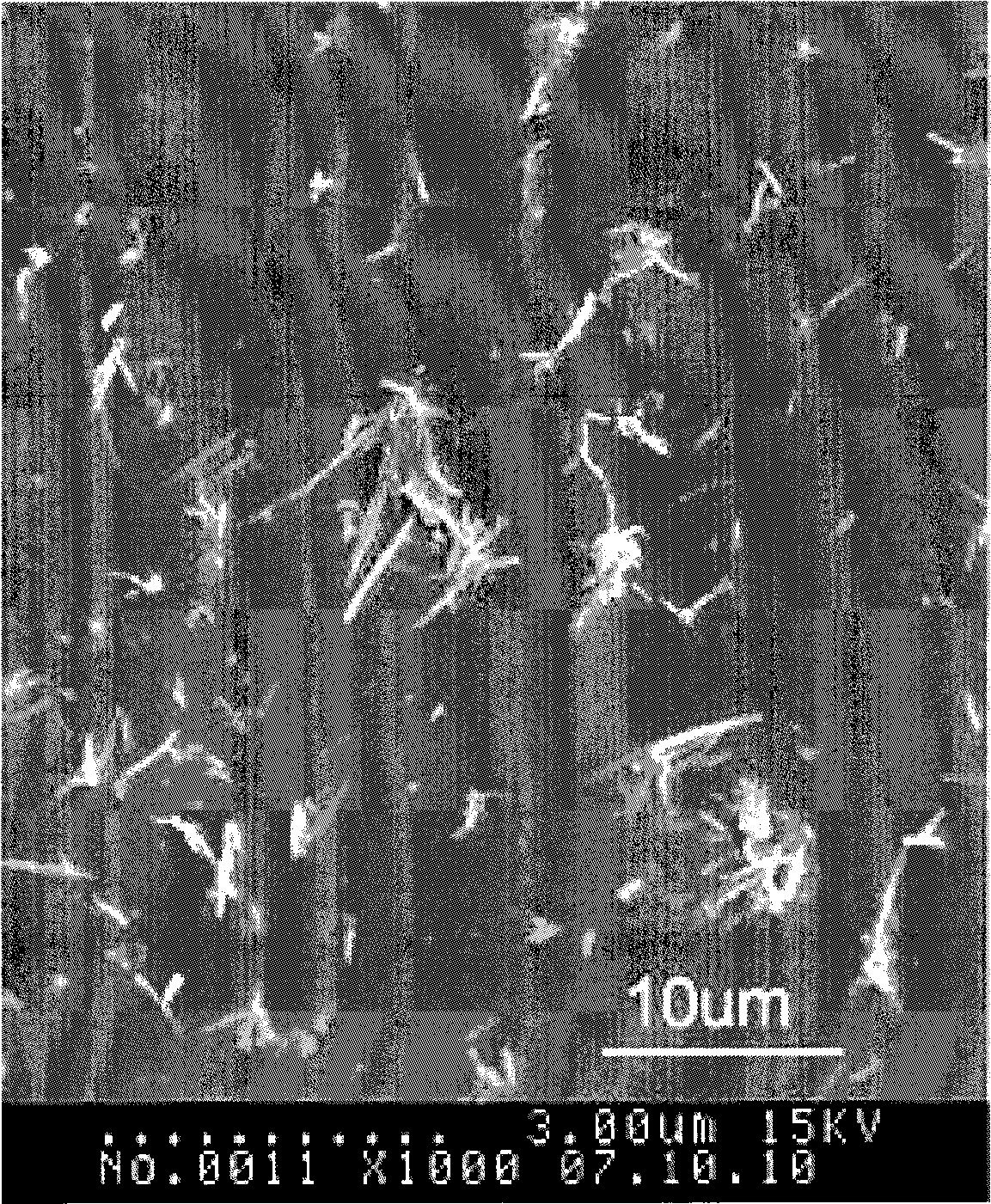

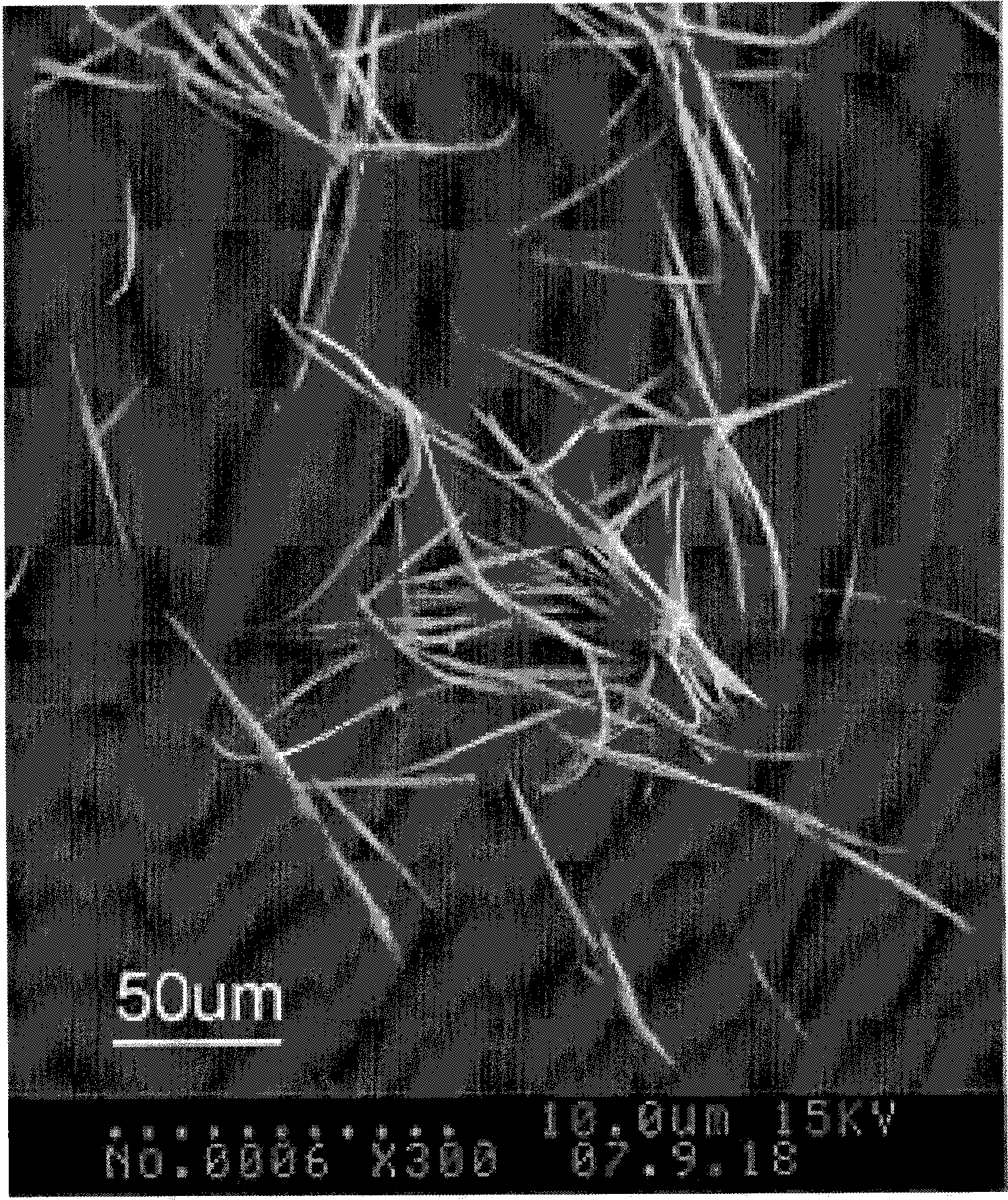

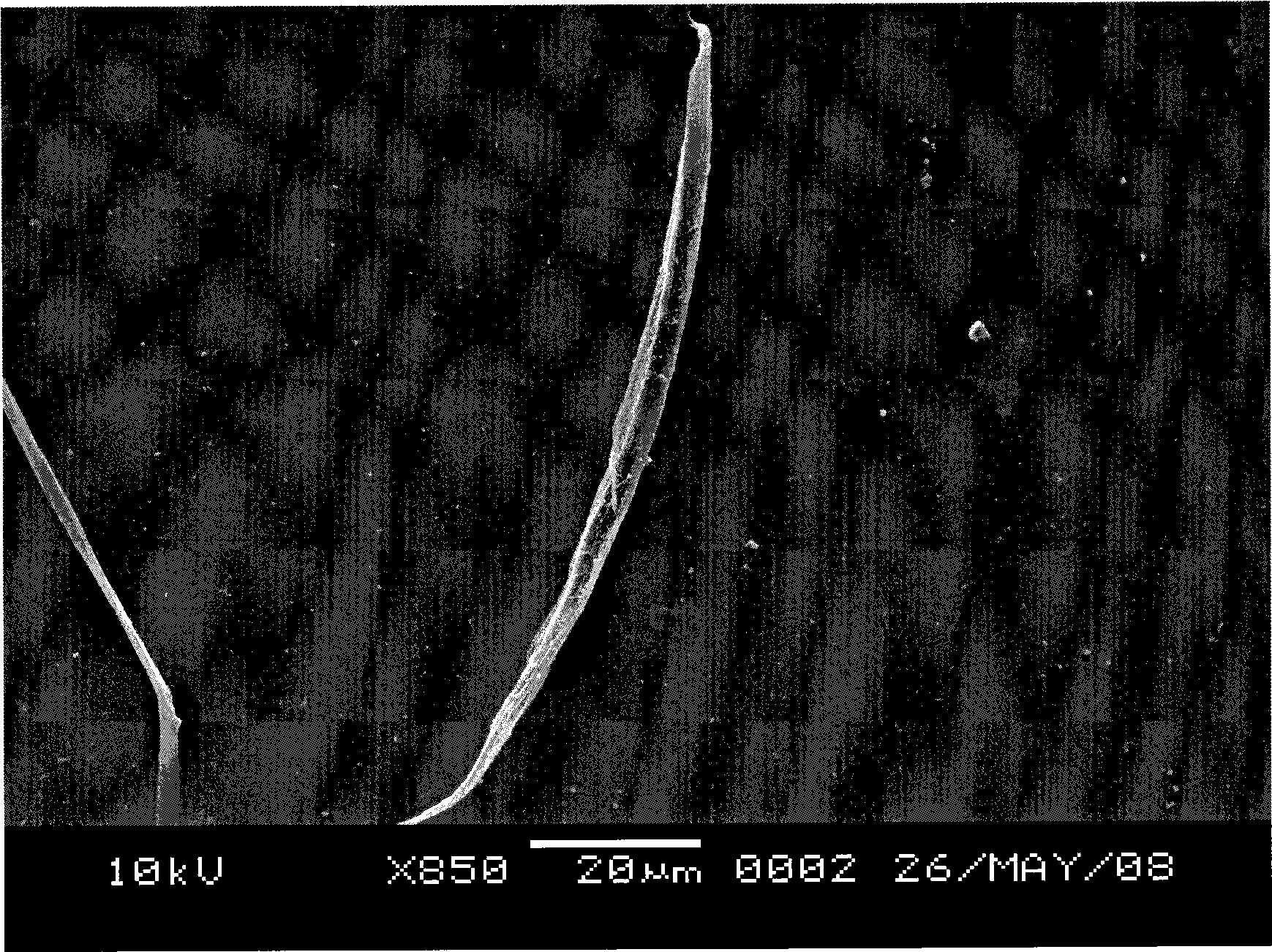

[0028] The mixture obtained after stirring is filtered with an 80-mesh screen to remove unreacted natural keratin fibers, and the filtrate is filtered with a 450-mesh screen to obtain a fibril structure with a diameter of 2-4 μm (80-120 μm in length). Centrifuge at 18°C at 7000rpm for 0.2h to obtain a fibril-like structure with a diameter of 0.2-0.4 μm (20-50 μm in length) and the centrifuged supernatant, wash the obtained fibril-like structure with distilled water, Centrifuge at 7000rpm for 0.2h and then air-dry naturally; dialyze and concentrate th...

Embodiment 2

[0031] Wash 6.25g of yak hair after loosening and removing impurities with absolute ethanol, cut it into 5mm segments after drying, and immerse it in 250ml of a solution (pH=7.2) containing potassium bisulfite and thiourea, wherein the The above solution is obtained by adding potassium bisulfite to 6M thiourea aqueous solution, the mass concentration of potassium bisulfite is 12%, stirring at 60° C. for 8 h, and the speed of the stirrer is 400 r / min.

[0032] The mixture obtained after stirring is filtered with a 120-mesh screen to remove unreacted natural keratin fibers, and the filtrate is filtered with a 350-mesh screen to obtain a fibril structure with a diameter of 2-4 μm (80-120 μm in length). Centrifuge at 22°C at a speed of 3000rpm for 1h to obtain a fibrillar structure with a diameter of 0.2-0.4μm (20-50μm in length) and the centrifuged supernatant, wash the obtained fibril-like structure with distilled water, and store Centrifuge at 3000rpm for 1 hour and then air-dr...

Embodiment 3

[0035] 5g of the discarded horse hair after loosening and removing impurities was cleaned with ether, dried and cut into 5mm segments, which were immersed in 250ml of a solution (pH=6.8) containing sodium sulfite and lithium bromide, wherein the solution was obtained by adding sodium sulfite Add it to 10M lithium bromide aqueous solution, the mass concentration of sodium sulfite is 10%, stir at 70°C for 6h, and the speed of the stirrer is 500r / min.

[0036] The mixture obtained after stirring is filtered with a 100-mesh screen to remove unreacted natural keratin fibers, and the filtrate is filtered with a 400-mesh screen to obtain a fibril structure with a diameter of 2-4 μm (80-120 μm in length). Centrifuge at 15°C at a speed of 5000rpm for 0.4h to obtain a fibrillar structure with a diameter of 0.2-0.4 μm (20-50 μm in length) and a centrifuged supernatant, wash the obtained fibril-like structure with distilled water, and Centrifuge at 5000rpm for 0.4h and then air-dry natura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com