Method for producing nodulizing agent

A production method and technology of a nodularizing agent, applied in the field of nodularizing agent, can solve the problems of low absorption rate of effective elements and violent reaction, and achieve the effects of less segregation of chemical components, elimination of environmental pollution, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

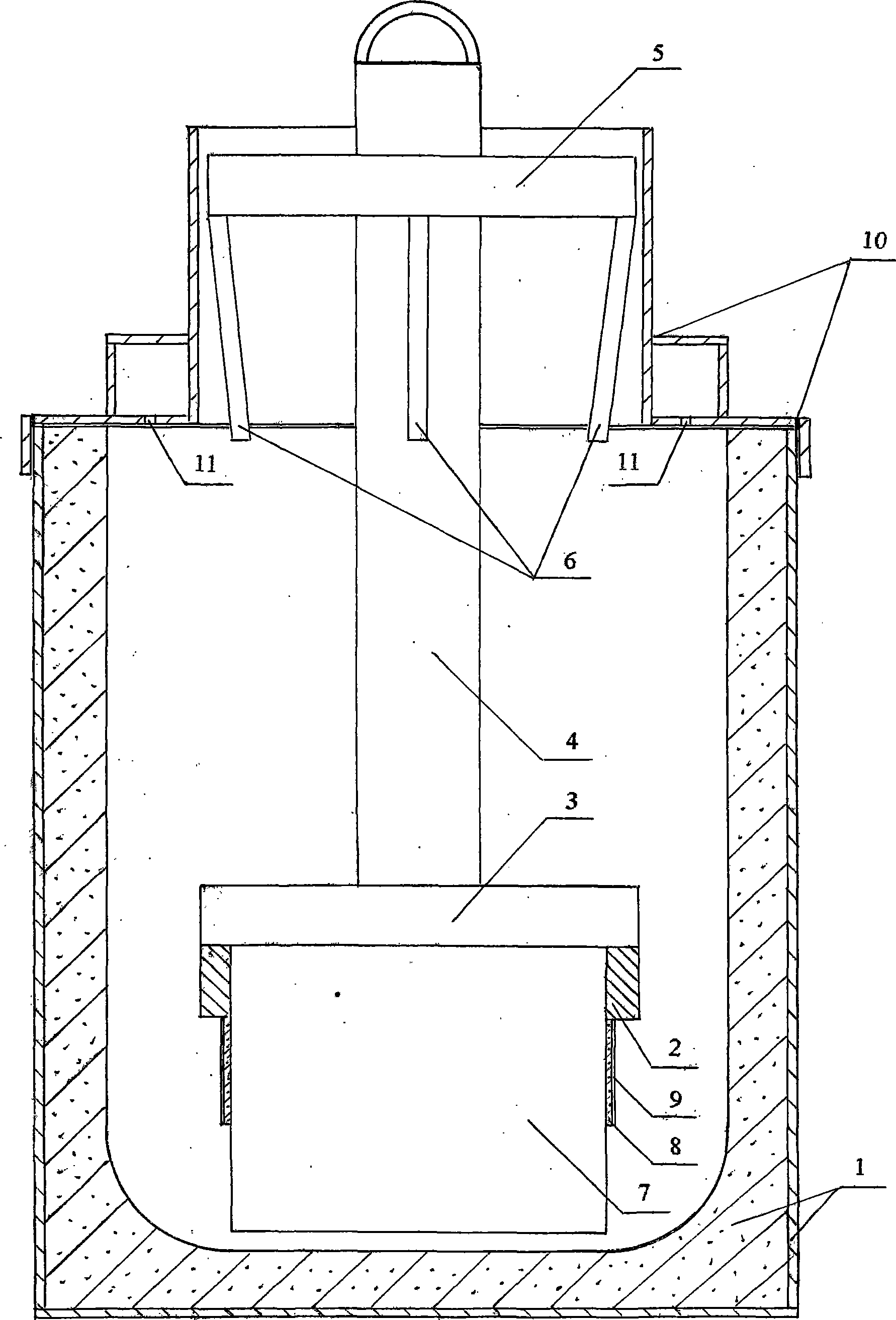

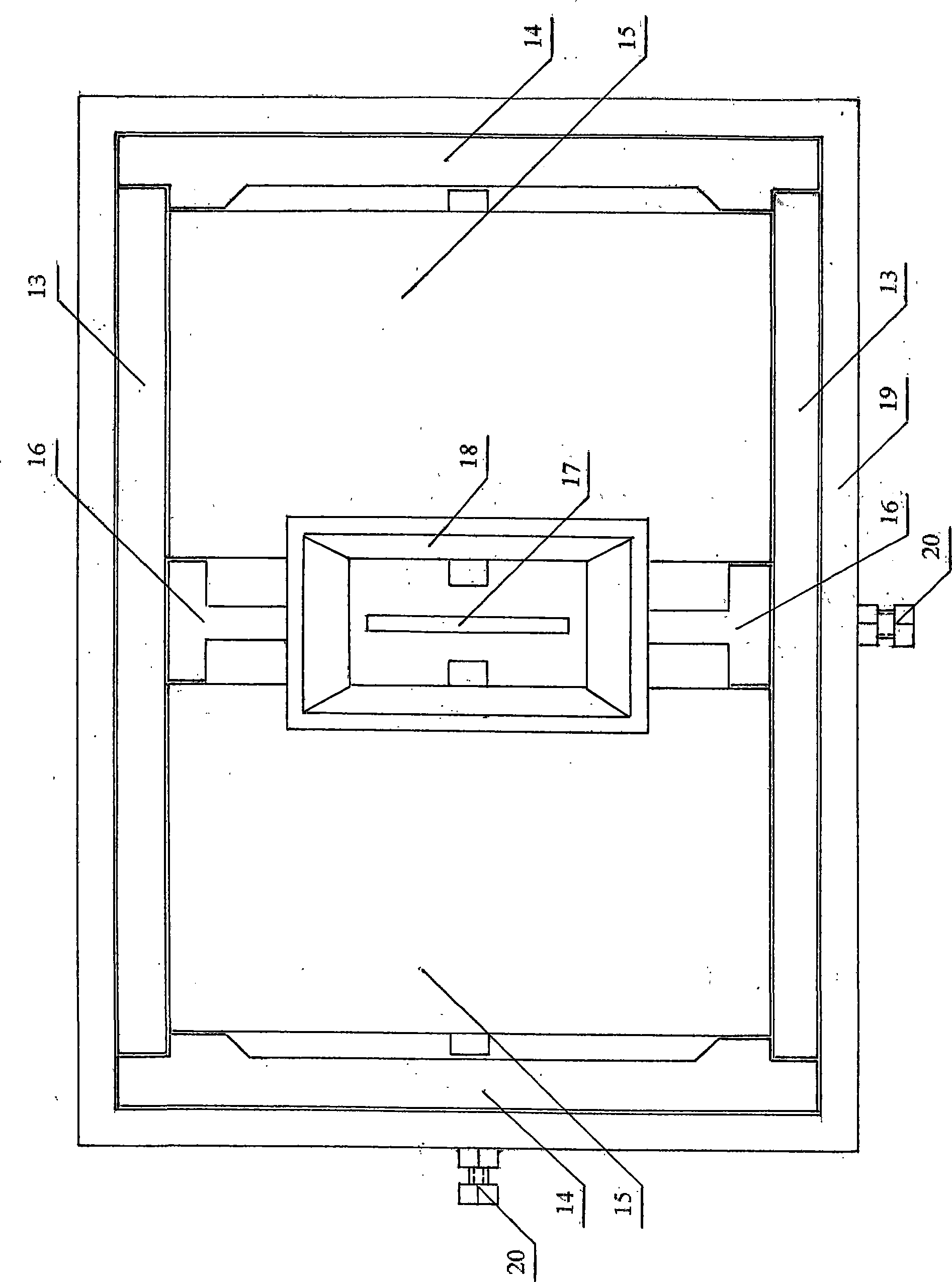

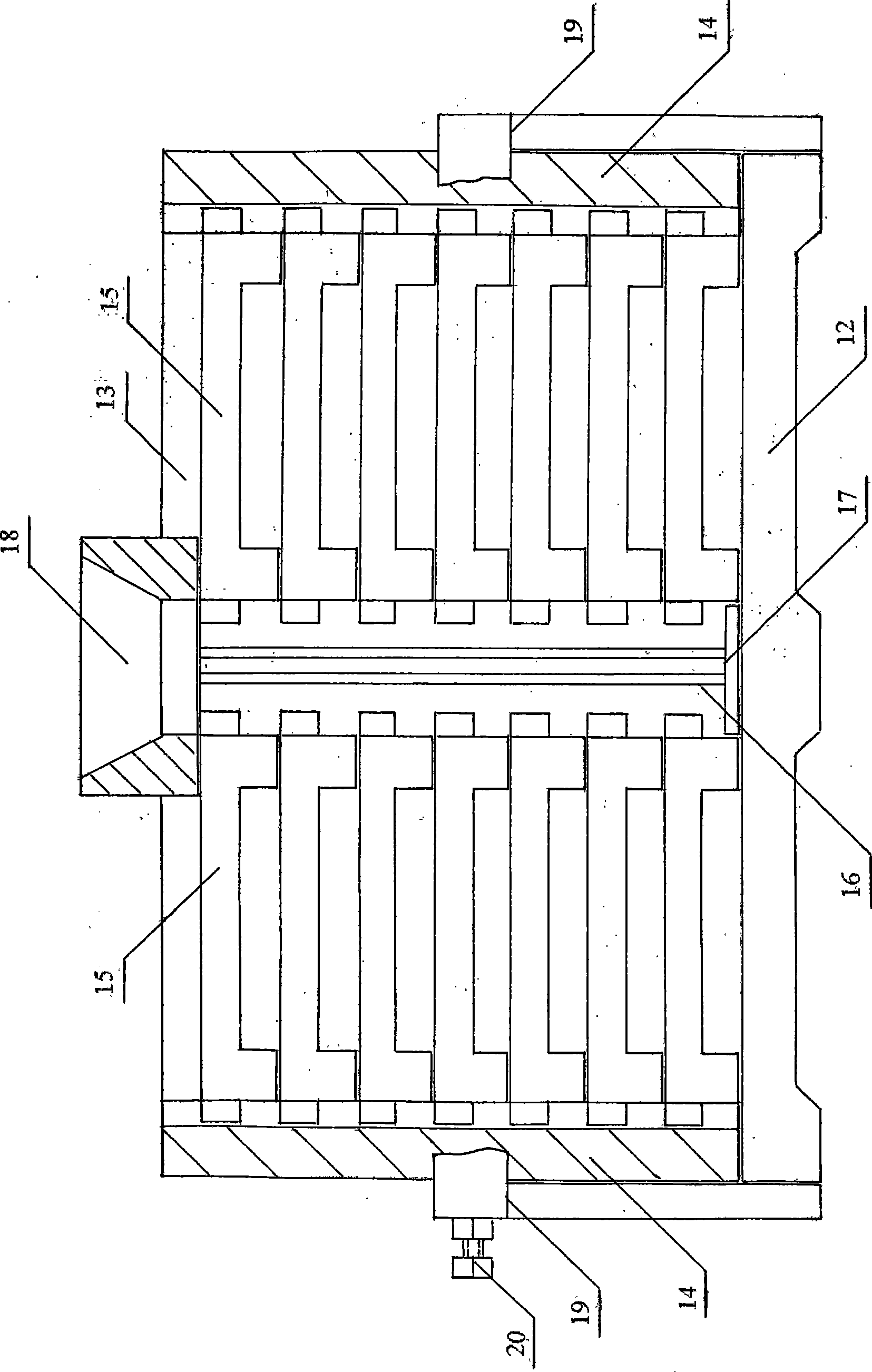

[0017] The implementation of the present invention will be further described in conjunction with the accompanying drawings:

[0018] Before pressing into the metal magnesium 7, for the spheroidizing agent injected into the ladle, the silicon content of the multi-element alloy liquid is in the range of 43% to 48%, and the temperature of the multi-element alloy liquid is between 1280 and 1330 when the magnesium is pressed. ℃, in order to reduce the cooling of the multi-component alloy liquid and reduce the melting loss of the sleeve 2, the lower pressure plate 3, and the pressure column 4, the outer layer is coated with refractory and heat-insulating materials. When the sleeve 2 touches the bottom of the processing bag 1, the bottom of the upper platen 5 should be at the upper port of the processing bag 1 to reduce the space above the liquid level of the alloy in the bag when the magnesium alloy reacts. The distance between the core plates 15 of each layer in the combined molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com