A method for treating zinc smoke

A treatment method and technology for soot, applied in the direction of improving process efficiency, etc., can solve problems such as accumulation of Zn, nodules on the upper part of the furnace body, blockage of gas riser pipes and dust removal bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

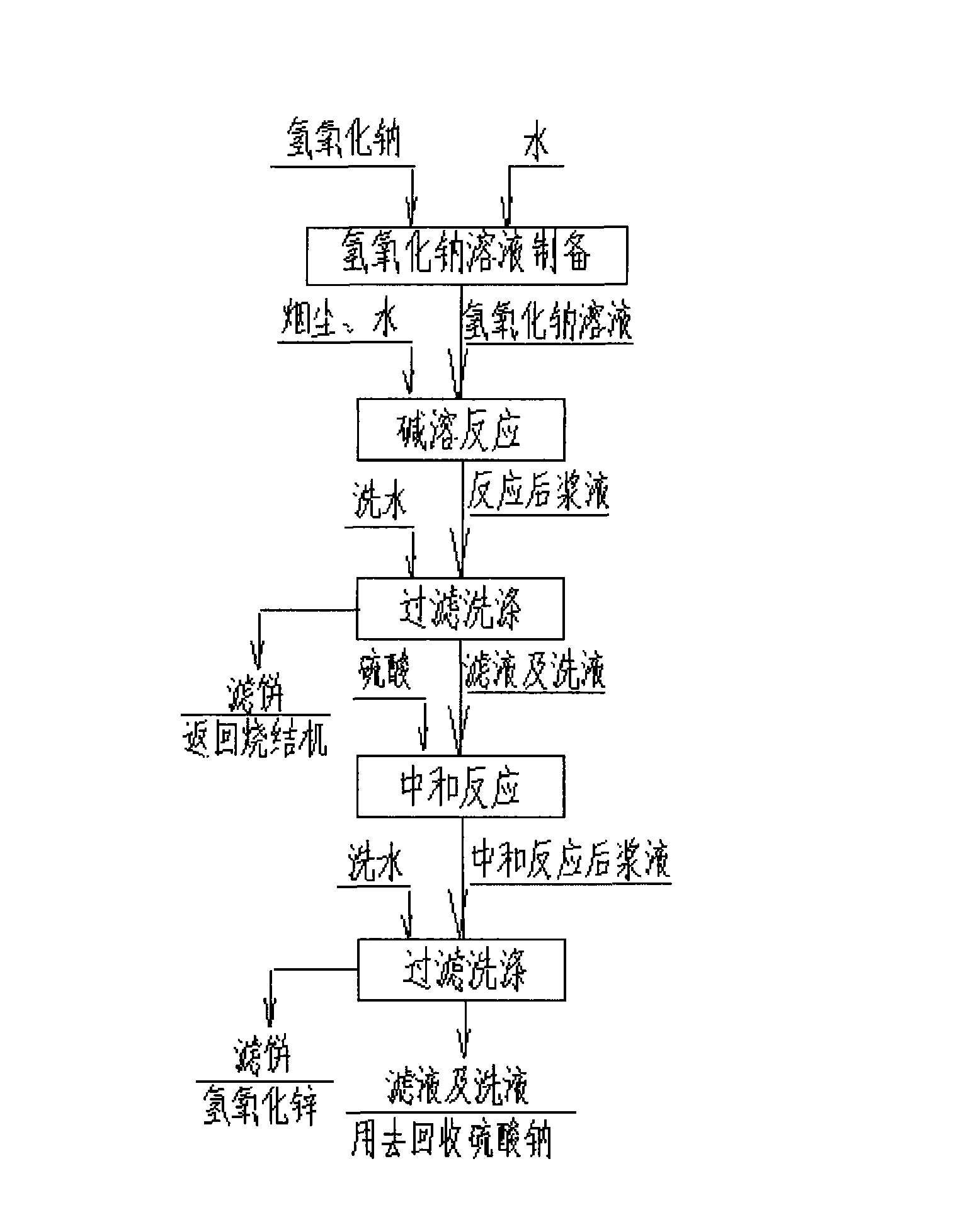

[0014] see figure 1 , for zinc-containing blast furnace dust and electric furnace dust produced in the process of iron and steel smelting, using the amphoteric characteristics of Zn to show acidity when it meets strong alkali and alkali when meeting strong acid, Fe and its oxides and C are not dissolved by strong alkali, so use strong alkali NaOH solution is used to treat blast furnace and electric dust, so that Zn, ZnO and NaOH react to form soluble compounds and enter the liquid phase, while Fe and its oxides, C, SiO, Al 2 o 3 , CaO, etc. do not react with NaOH and remain in the solid phase. Then, it was filtered and washed to separate the solid from the liquid. Solid phase filter cake contains Fe and its oxides, C, SiO, Al 2 o 3 , CaO, etc., return to the sintering machine for reuse. Soluble compounds containing Zn in the liquid phase, with H 2 SO 4 Neutralization, Zn is converted to Zn(OH) 2 Precipitate, then filter and wash, the filter cake is Zn(OH) 2 Used to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com