Method for controlling crystalline products in wet flue gas desulfurization slurry pool

A control method and slurry pool technology, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of reducing the commissioning rate of desulfurization devices, thinning slurry filtration, and outage of flue gas desulfurization devices, etc. Mass spawning, eliminating spawning conditions, avoiding blindness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

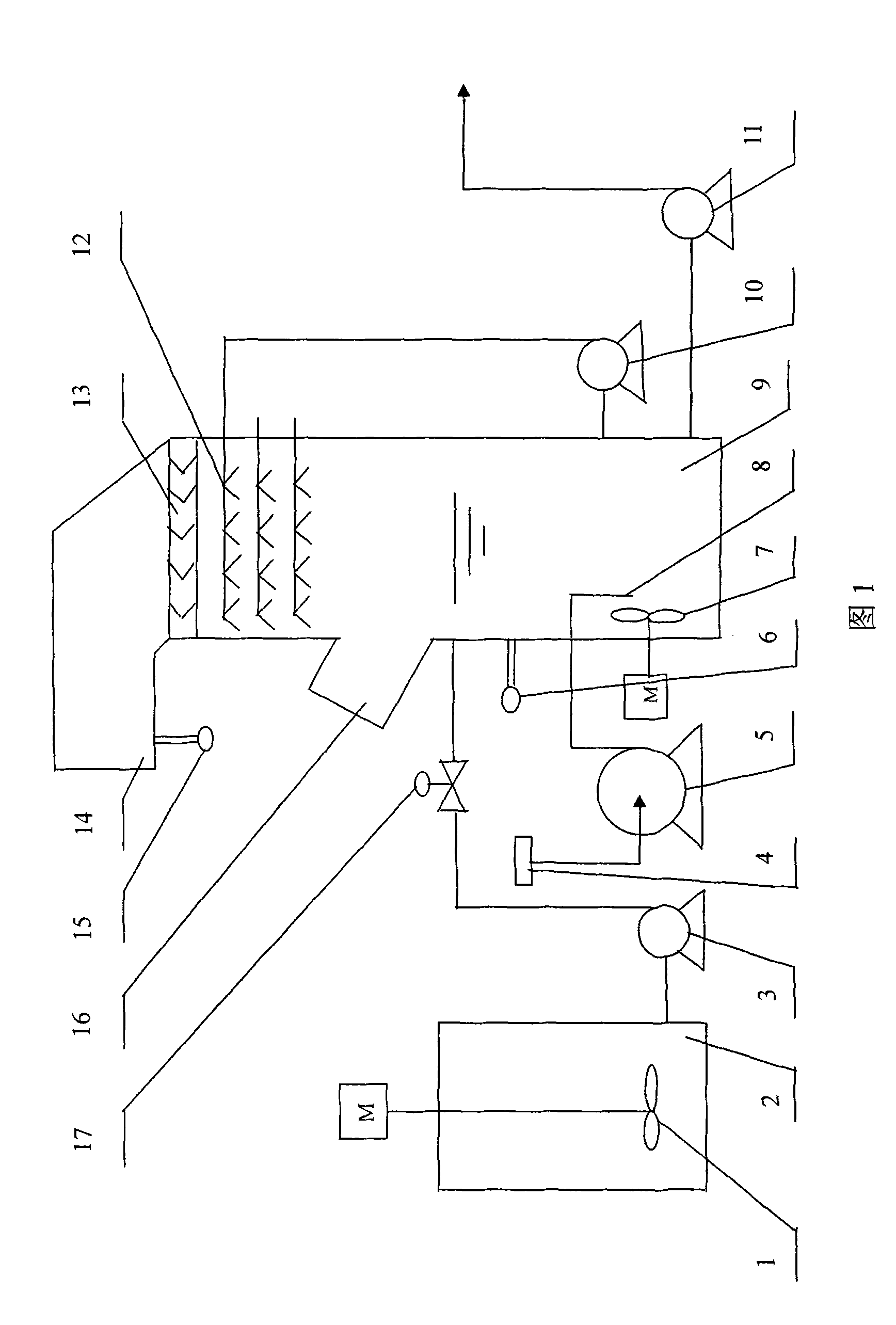

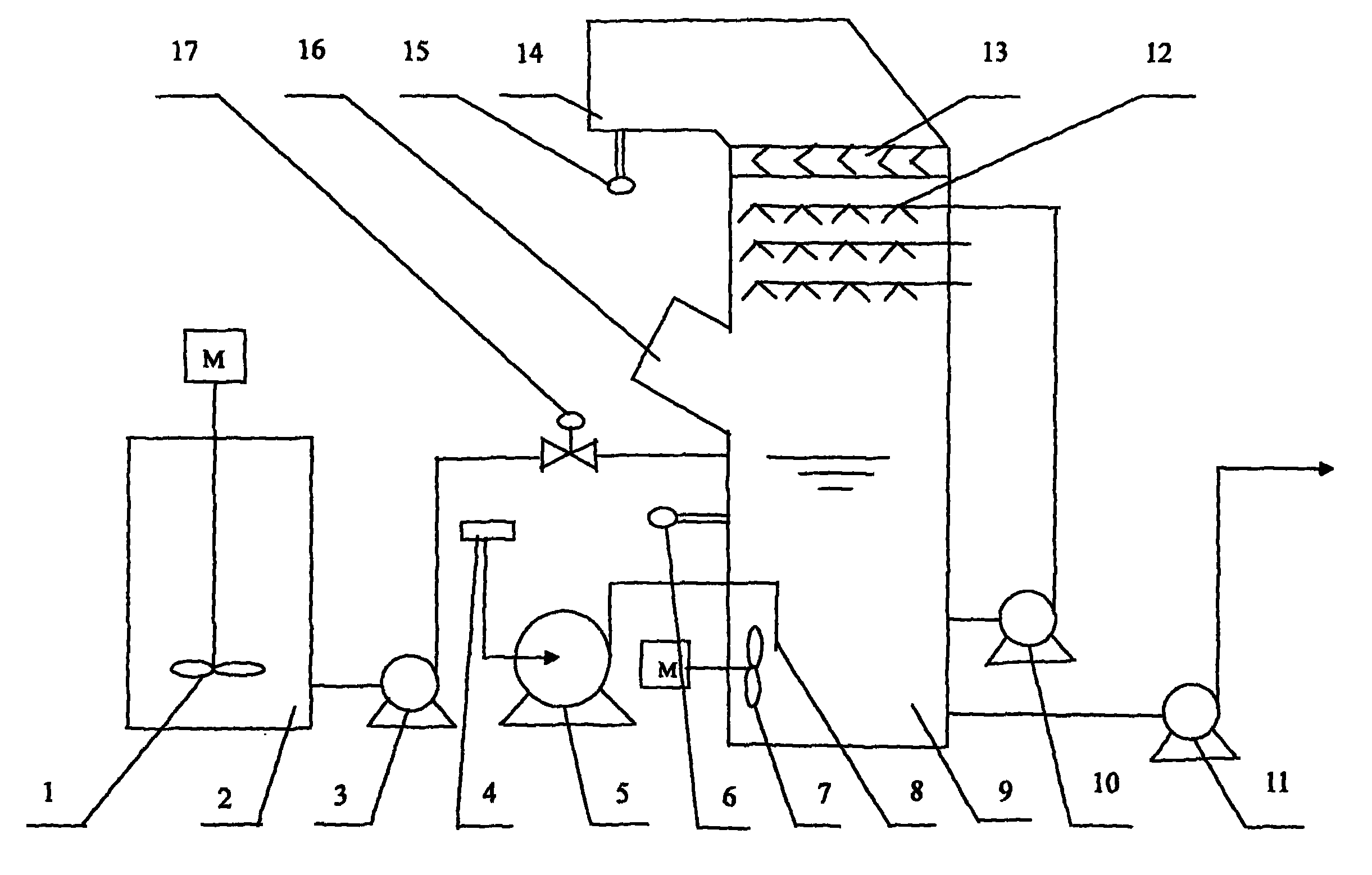

[0032] Such as figure 1 Shown, method of the present invention comprises:

[0033] (1) Measure the oxygen concentration in the clean flue gas by an oxygen measuring instrument installed in the clean flue 14 above the slurry tank 9, and judge the adequacy of the instantaneous oxygen supply in the slurry tank 9 according to the measurement results of the oxygen concentration in the clean flue gas, The opening degree of the air-conditioning door 4 of the air blower 5 is automatically adjusted by a program-controlled manner to inject the required amount of oxidizing air into the oxidizing air spray gun 8 so as to maintain a moderate oxygen supply to the slurry tank 9 . The slurry is sucked into the slurry pool 9 by the slurry circulating pump 10 and sprayed downward through the sprayer 12 above it, contacting the original smoke that enters the space below the sprayer 12 from the original smoke inlet 16 and turns upward and countercurrently, absorbing The sulfur dioxide in the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com