Corrosion resistant hydrotalcite/polyelectrolyte composite film and preparation method thereof

A technology of polyelectrolyte and corrosion resistance, which is applied in the field of corrosion inhibitor intercalated hydrotalcite/polyelectrolytic composite film and its preparation, can solve the problems of poor toughness, insufficient density of the film, and short anti-corrosion life, and achieve uniform and dense film formation , strong binding force and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

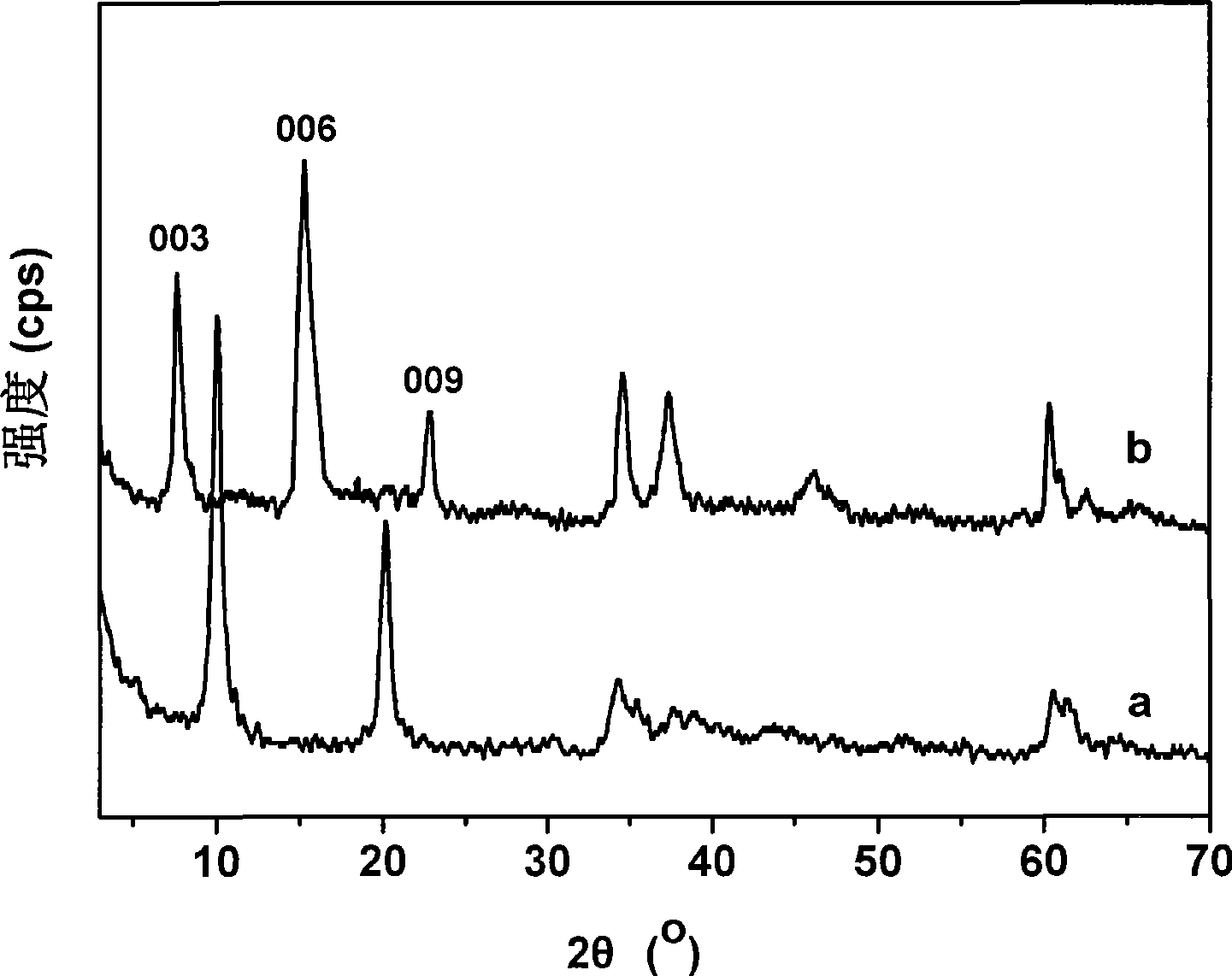

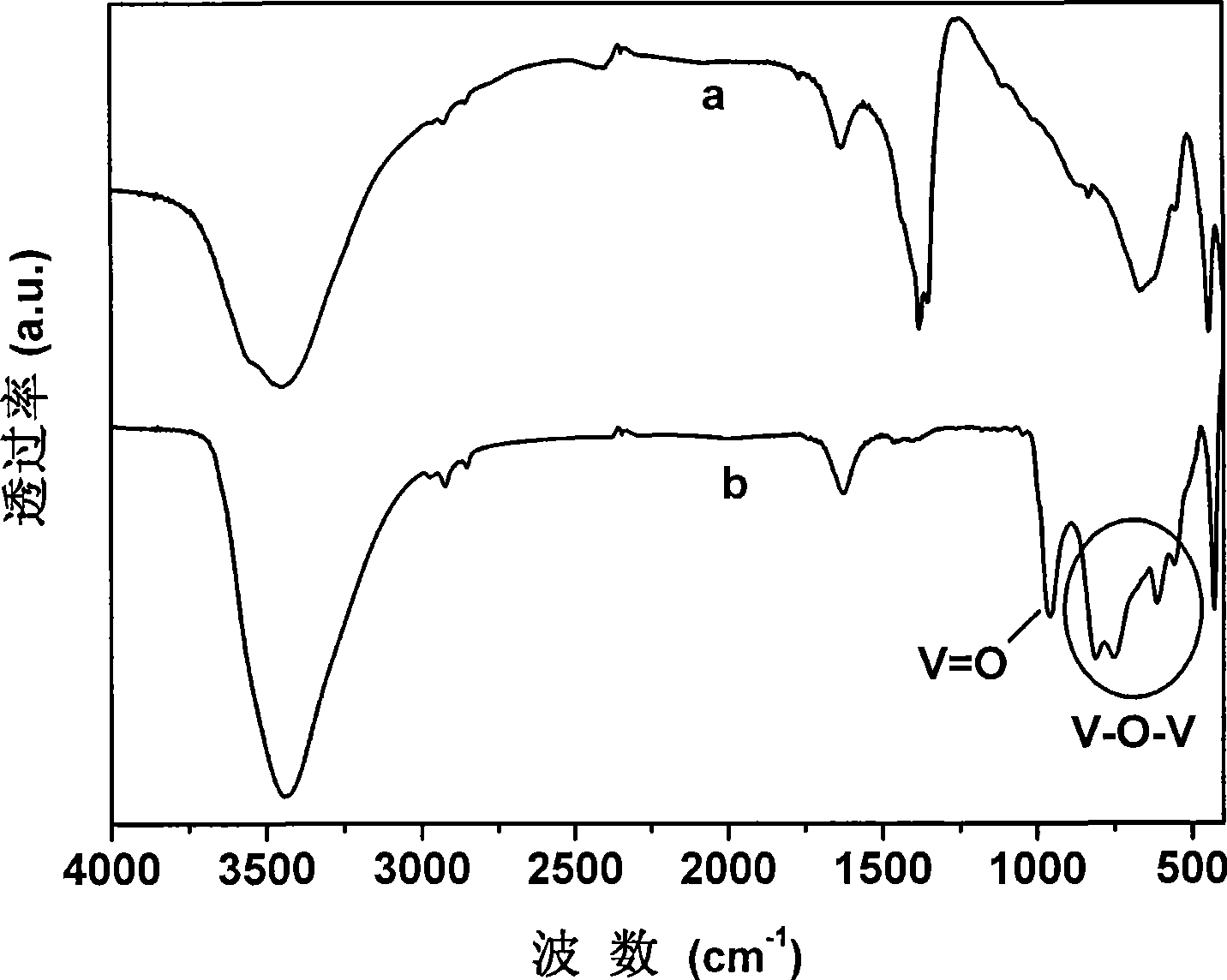

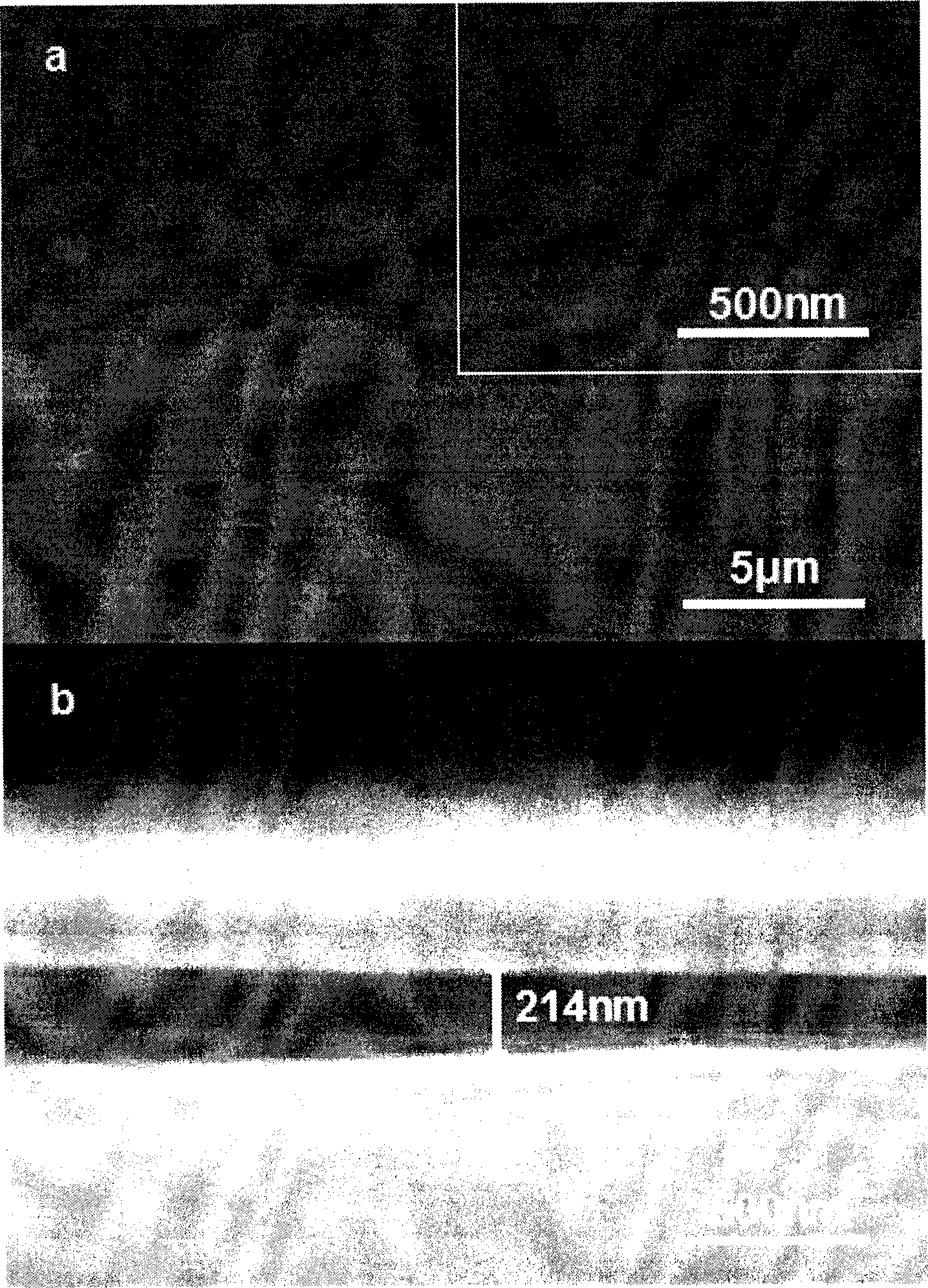

[0028] Weigh 28.56g Zn(NO 3 ) 2 ·6H 2 O and 9.00g Al(NO 3 ) 3 9H 2 O dissolved in 150mL to remove CO 2 In water, prepare a mixed salt solution, take another 9.12g NaOH and dissolve it in 150mL to remove CO 2 In water, the alkaline solution and the mixed salt solution were quickly poured into the colloid mill at room temperature for 1 minute to react, the resulting slurry was hydrothermally crystallized at 120° C. for 8 hours, and the obtained sample was washed to pH=7. The resulting sample was dried at 60°C for 24 hours and ground to obtain nitrate-intercalated zinc-aluminum hydrotalcite (Zn / Al=2) powder; weigh 0.1g nitrate-intercalated zinc-aluminum hydrotalcite powder and 4.0g NaVO 3 Add to 100mL to remove CO 2 In water, use HNO with a concentration of 1.0mol / L 3 Adjust pH=5, pass N at 70°C 2 Perform ion exchange for 48 hours, using CO removal 2 The deionized water was washed to pH = 7 to obtain decavanadate intercalated zinc aluminum hydrotalcite (Zn / Al = 2). Acc...

Embodiment 2

[0032] Weigh 15.384g Mg(NO 3 ) 2 ·6H 2 O and 11.253g Al(NO 3 ) 3 9H 2 O dissolved in 50 mL to remove CO 2 In water, prepare a mixed salt solution, take another 6.84g NaOH and dissolve it in 50mL to remove CO 2 In water, quickly pour the alkali solution and the mixed salt solution into the colloid mill at room temperature to react for 1 minute, and the obtained slurry was hydrothermally crystallized at 140° C. for 10 hours, and the obtained sample was washed to pH=7.5. The resulting sample was dried at 70°C for 20 hours and ground to obtain nitrate-intercalated magnesium-aluminum hydrotalcite (Mg / Al=2) powder; weigh 0.1g nitrate-intercalated magnesium-aluminum hydrotalcite powder and 4.0g NaVO 3 Add to 100mL to remove CO 2 In water, use HNO with a concentration of 1.0mol / L 3 Adjust pH=5, pass N at 50°C 2 Ion exchange was carried out for 72 hours, centrifuged and washed to pH=7.5. CO removal 2 The deionized water was washed to pH = 7.5 to obtain decavanadate intercala...

Embodiment 3

[0036] Weigh 23.220g Co(NO 3 ) 2 ·6H 2 O and 10.010g Al(NO 3) 3 9H 2 O dissolved in 100mL to remove CO 2 In water, prepare a mixed salt solution, take another 8.117g NaOH and dissolve it in 100mL to remove CO 2 In water, quickly pour the alkali solution and the mixed salt solution into the colloid mill at room temperature to react for 1 minute, and the resulting slurry was hydrothermally crystallized at 160° C. for 12 hours, and the obtained sample was washed to pH=7. The resulting sample was dried at 80°C for 12 hours and ground to obtain nitrate-intercalated cobalt-aluminum hydrotalcite (Co / Al=3) powder; weigh 0.1 g of nitrate-intercalated cobalt-aluminum hydrotalcite powder and 4.0 g of NaVO 3 Add to 100mL to remove CO 2 In water, use HNO with a concentration of 1.5mol / L 3 Adjust pH=5.5, pass N at 60°C 2 Perform ion exchange for 60 hours, using CO removal 2 The deionized water was washed to pH = 7 to obtain decavanadate intercalated cobalt aluminum hydrotalcite (C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com