Analysis method for reliability of numerical control equipment based on hidden Markov chain

An analysis method and reliability technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as the inability to understand the real-time changes and large quantities of CNC equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

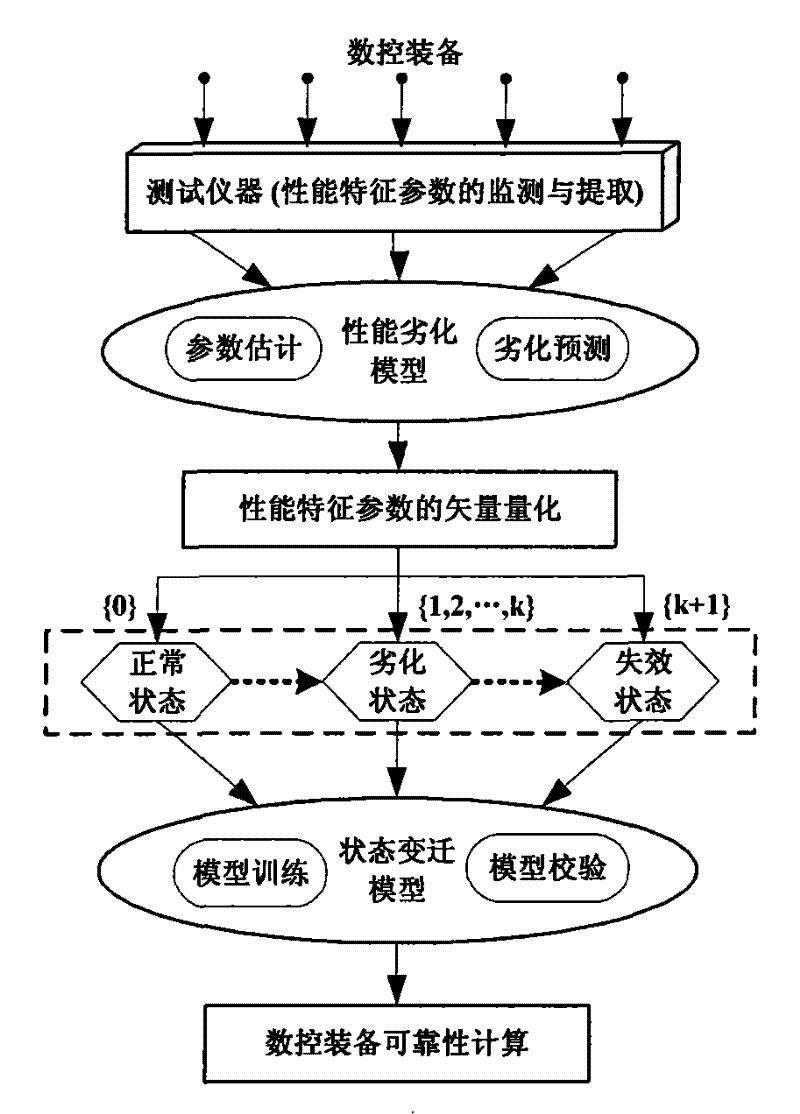

AI Technical Summary

Problems solved by technology

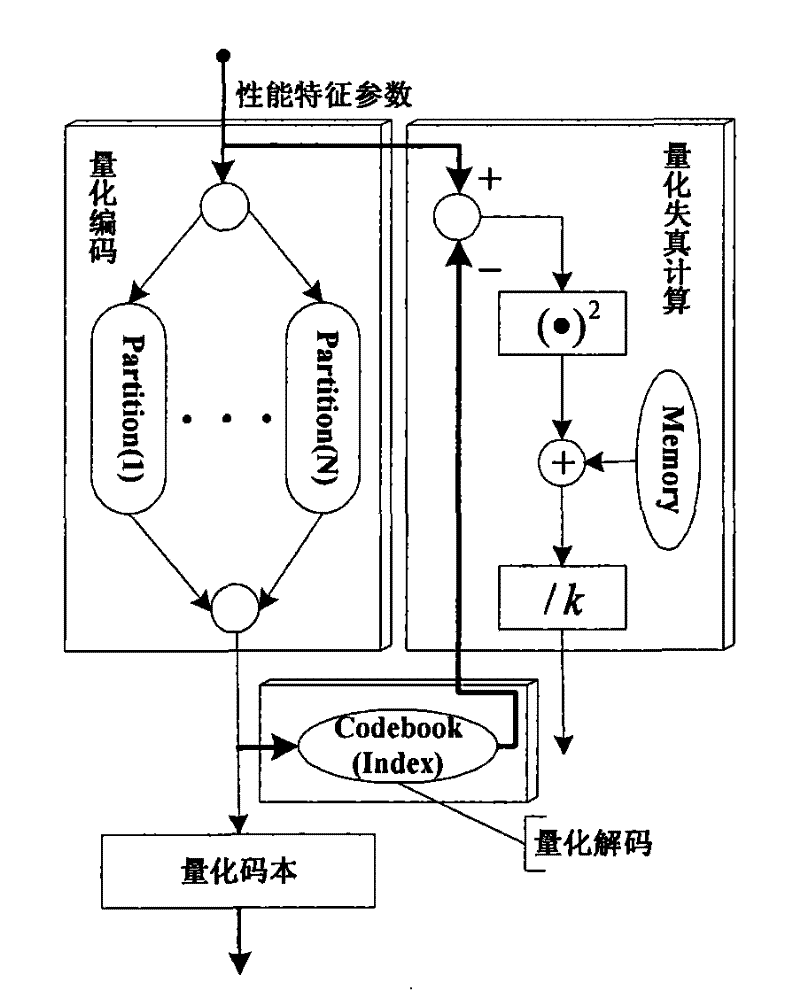

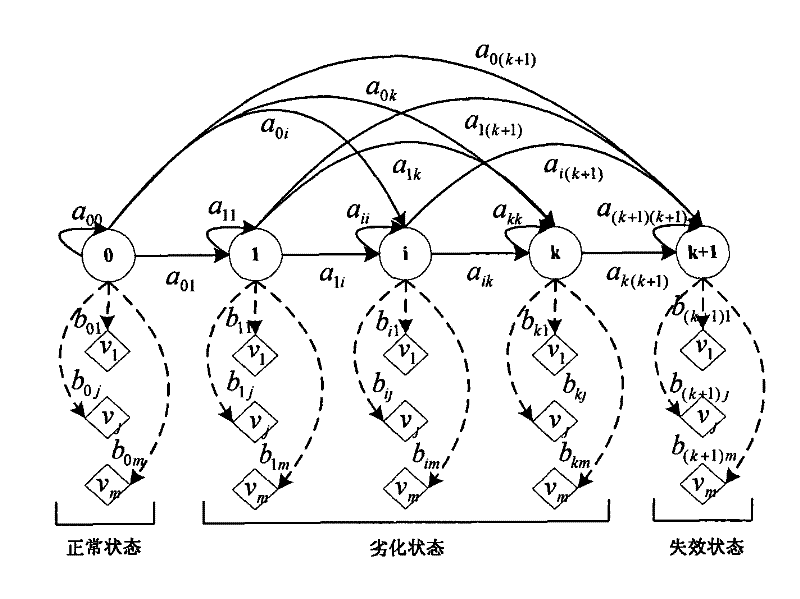

Method used

Image

Examples

Embodiment

[0075] This embodiment provides a specific implementation process of the present invention in engineering practice, and at the same time verifies the effectiveness of the present invention.

[0076] Reference Figure 4 , Taking Outai OTM-650 CNC milling machine as the research object, by simulating the deterioration of the circular motion accuracy of the equipment caused by the backlash, infer the law of the reliability of the CNC equipment. The test equipment includes Othai OTM-650 CNC milling machine, Huazhong "Century Star" CNC system HMC-21M, Heidenhain KGM182 plane grating measuring device and ordinary PC. Among them, the plane grating KGM182 is a high-precision test instrument used for non-contact measurement of the two-dimensional motion profile accuracy of equipment. Through NC programming, the worktable makes a counterclockwise / clockwise circular motion in the XOY plane with a radius of 50mm and a feed speed of 2000mm / min, and a plane grating is used to measure the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com