A zero-discharge treatment method and system for desulfurization wastewater adapted to multiple working conditions

A technology for desulfurization wastewater and treatment method, which is applied in the fields of gaseous discharge wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., which can solve the problem of insufficient sources of desulfurization wastewater, failure to achieve zero discharge of desulfurization wastewater, and insufficient operating conditions. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

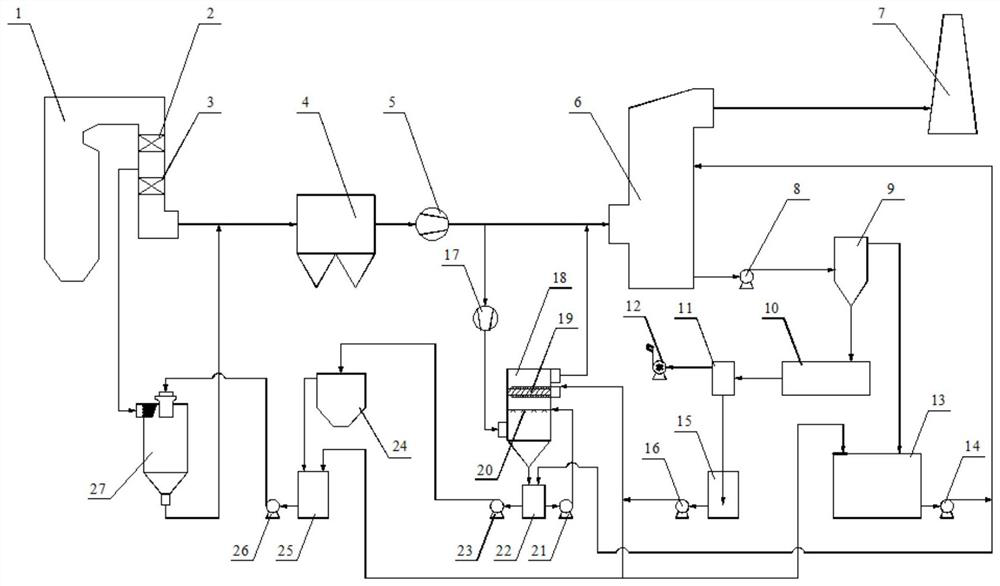

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

[0034] refer to figure 1 , the zero-discharge treatment system for desulfurization wastewater adapted to multiple working conditions according to the present invention includes a boiler 1, a dust collector 4, a desulfurization absorption tower 6, a chimney 7, a gypsum cyclone 9, a filtrate tank 13, a gypsum dehydrator 10, a gas-liquid Separation tank 11, waste water collection tank 15, waste water concentration tower 18, thick slurry tank 22, clarifier 24, spray water tank 25 and waste water drying tower 27; the tail flue of boiler 1 is provided with an economizer 2 along the flue gas flow direction And the air preheater 3, the tail flue of the boiler 1 and the bottom outlet of the waste water drying tower 27 are all connected with the inlet of the dust collector 4, and the outlet of the dust collector 4 is connected with the flue gas inlet of the waste water concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com