Optically functional film

A technology of optical function and optical function layer, applied in optics, optical components, thin material processing, etc., can solve the problems of poor fingerprint resistance, poor resistance to marking ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

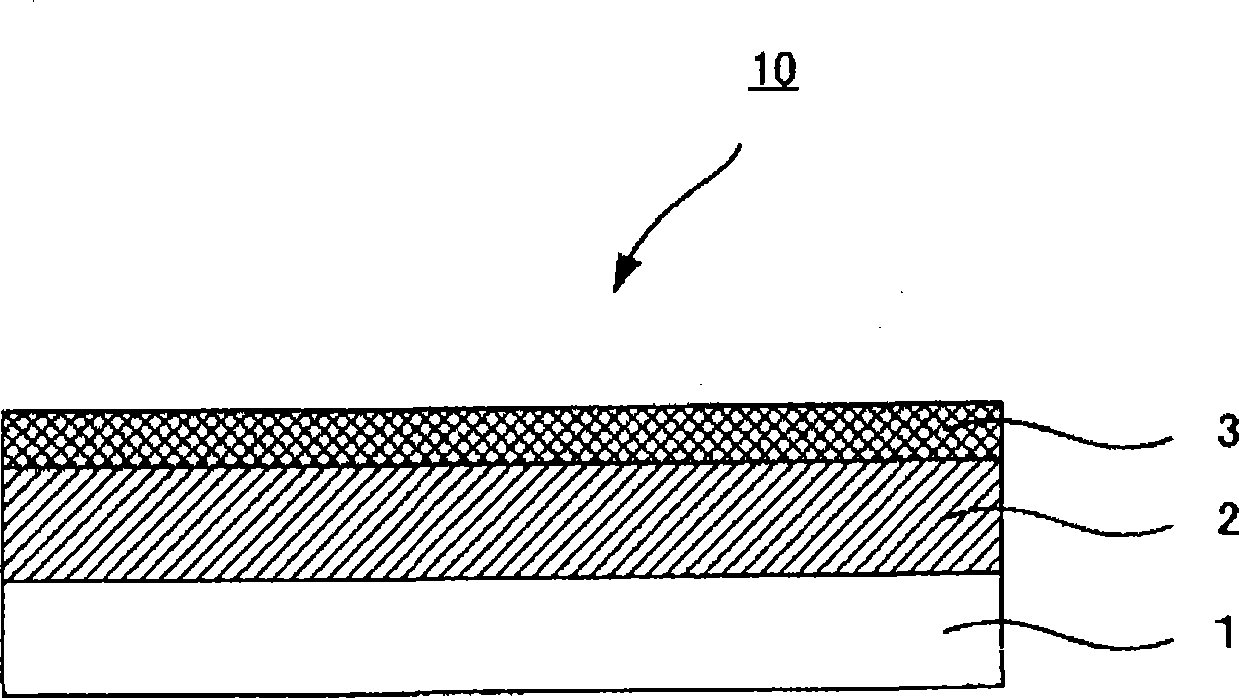

Image

Examples

Embodiment 1

[0216] (1) Formation of hard coating

[0217] (Preparation of composition for forming a hard coat layer)

[0218] Components of the following compositions were mixed to prepare a composition for forming a hard coat layer.

[0219] ・Pentaerythritol triacrylate (PET-30: trade name, manufactured by Nippon Kayaku); 30.0 parts by mass

[0220] ・Egacure 907 (trade name, manufactured by Chiba Special Chemicals Co., Ltd.): 1.5 parts by mass

[0221] Methyl isobutyl ketone: 73.5 parts by mass

[0222] (production of hard coat)

[0223] On a triacetyl cellulose (TAC) film with a thickness of 80 μm, the composition for forming a hard coat layer prepared above was bar-coated, and after removing the solvent by drying, a radiation dose of about 20 mJ / cm was applied using an ultraviolet irradiation device. 2 The coating film was cured by ultraviolet irradiation to obtain a laminated film having a hard coat layer having a film thickness of 10 μm and consisting of a base material / hard coat...

Embodiment 2

[0237] Except that the composition for forming the low refractive index layer is made into the following components, it is carried out in the same manner as in Example 1 to obtain a substrate / hard coat layer / low refractive index layer / antifouling layer (formed by exudation). Optical functional film with layer structure.

[0238] (Composition for forming a low refractive index layer)

[0239] ・Hollow silica microparticle dispersion (hollow silica methyl isobutyl ketone sol; average particle diameter 50 nm, solid content 20%, manufactured by Catalyst Chemical Industry Co., Ltd.); 13.6 parts by mass

[0240] Pentaerythritol triacrylate (PET-30: trade name, manufactured by Nippon Kayaku); 1.8 parts by mass

[0241] ・Egacur 127 (trade name, manufactured by Chiba Special Chemicals Co., Ltd.): 0.1 parts by mass

[0242] · ZX-007C (solid content 35%, trade name, manufactured by Fuji Chemical Industries, fluororesin / siloxane graft type polymer); 0.5 parts by mass

[0243]5088X (trad...

Embodiment 3

[0246] (1) Formation of substrate / hard coat layer / low refractive index layer

[0247] It carried out similarly to Example 1, and obtained the laminated film which has a base material / hard-coat layer structure. Next, the composition for forming a low-refractive index layer was made to have the following composition, and a low-refractive index layer was formed on the laminated film.

[0248] (Composition for forming a low refractive index layer)

[0249] ・Hollow silica microparticle dispersion (hollow silica methyl isobutyl ketone sol; average particle diameter 50 nm, solid content 20%, manufactured by Catalyst Chemical Industry Co., Ltd.); 16.4 parts by mass

[0250] Pentaerythritol triacrylate (PET-30: trade name, manufactured by Nippon Kayaku); 1.6 parts by mass

[0251] ・Egacur 127 (trade name, manufactured by Chiba Special Chemicals Co., Ltd.): 0.1 parts by mass

[0252] Methyl isobutyl ketone: 81.9 parts by mass

[0253] (2) Formation of antifouling layer

[0254] Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com