Micro emulsion drug carrying system and manufacturing method thereof

A drug-carrying system and microemulsion technology, which is applied in the fields of pharmaceutical formulation, emulsion delivery, and medical preparations containing active ingredients, etc., can solve the problems of large amount of emulsifier used and damage to the body, and achieve good stability and prevent toxicity , Prescription simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the microemulsion drug-loading system of the present invention is completed by the following steps:

[0018] A, prepare materials by the weight ratio of medicinal oil: emulsifier: co-emulsifier: sodium chloride: water=1~25: 5~20: 5~25: 1~20: 50~85;

[0019] b. Mix the emulsifier and co-emulsifier evenly, add medicinal oil, and stir to obtain solution A;

[0020] c. After adding sodium chloride to solution A, add water and stir to form a microemulsion; or add solution A to sodium chloride aqueous solution and stir to form a microemulsion. Then transfer it to a dialysis bag, and repeatedly dialyze with physiological saline until the sodium chloride content is 0.85-0.9%.

[0021] In specific implementation, fat-soluble drugs can be added to the microemulsion drug-loading system of the present invention to obtain drug-loaded microemulsions. Its drug loading is 0.01-5%.

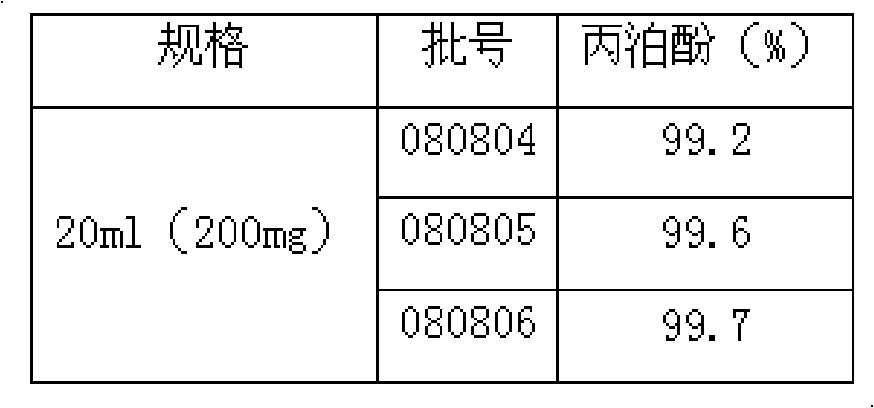

[0022] A specific embodiment of the present invention is to add propofol as...

Embodiment 1

[0024] Example 1 Preparation of microemulsion drug-carrying system of the present invention

[0025] Weigh 2g of polyene phosphatidylcholine, add 10g of glycerin, stir at 60°C to disperse polyene phosphatidylcholine, add 8g of Tween-80, stir, then add 2g of soybean oil, stir well, then add 17% chlorine 78 g of sodium chloride solution was stirred at 60° C. for 4 hours to obtain a transparent microemulsion with opalescence. The microemulsion was put into a dialysis bag with a molecular weight cut off of 5000, and the normal saline was dialyzed repeatedly, filtered with a 0.22 μm microporous membrane, and the average particle size of the microemulsion was determined to be 64 nm by dynamic light scattering.

Embodiment 2

[0026] Embodiment 2 Preparation of microemulsion drug-carrying system of the present invention

[0027] Weigh 2g of polyene phosphatidylcholine, add 10g of glycerin, stir at 60°C to disperse polyene phosphatidylcholine, add 10g of Tween-80, stir, then add 2g of soybean oil, stir well, then add 17% chlorine 76 g of sodium chloride solution was stirred at 60° C. for 4 hours to obtain an opalescent transparent microemulsion. The microemulsion was put into a dialysis bag with a molecular weight cut-off of 5000, repeatedly dialyzed with physiological saline, filtered with a 0.22 μm microporous membrane, and the average particle size of the microemulsion was determined to be 71 nm by dynamic light scattering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com