Lignin-modified diatomite and application thereof as rubber reinforcing agent

A technology of rubber reinforcing agent and diatomite, which is applied in the treatment of fibrous fillers and dyed polymer organic compounds, can solve problems such as pollution and environmental emissions, reduce production costs, simplify the preparation process, and solve emissions and environmental problems. Effects of Conservation Questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

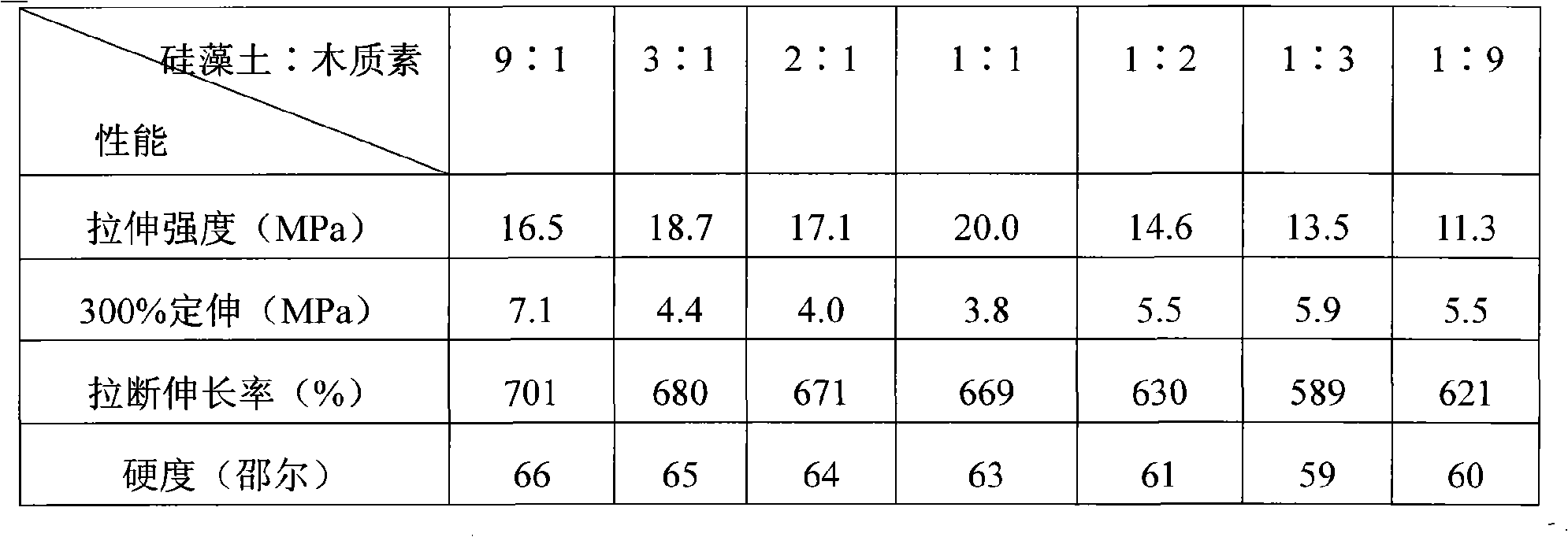

Embodiment 1

[0014] Add 10 grams of diatomite and 200 milliliters of deionized water in a 500 milliliter reactor, stir for 24 hours, then add 50 milliliters of papermaking black liquor containing 20% lignin by weight, continue to stir for 24 hours, then add hydrochloric acid to The pH of the slurry was 5-6, suction filtered, washed repeatedly until the filtrate was close to neutral, and finally dried at 75° C. for 15 hours to obtain 1:1 lignin-modified diatomite for future use.

Embodiment 2

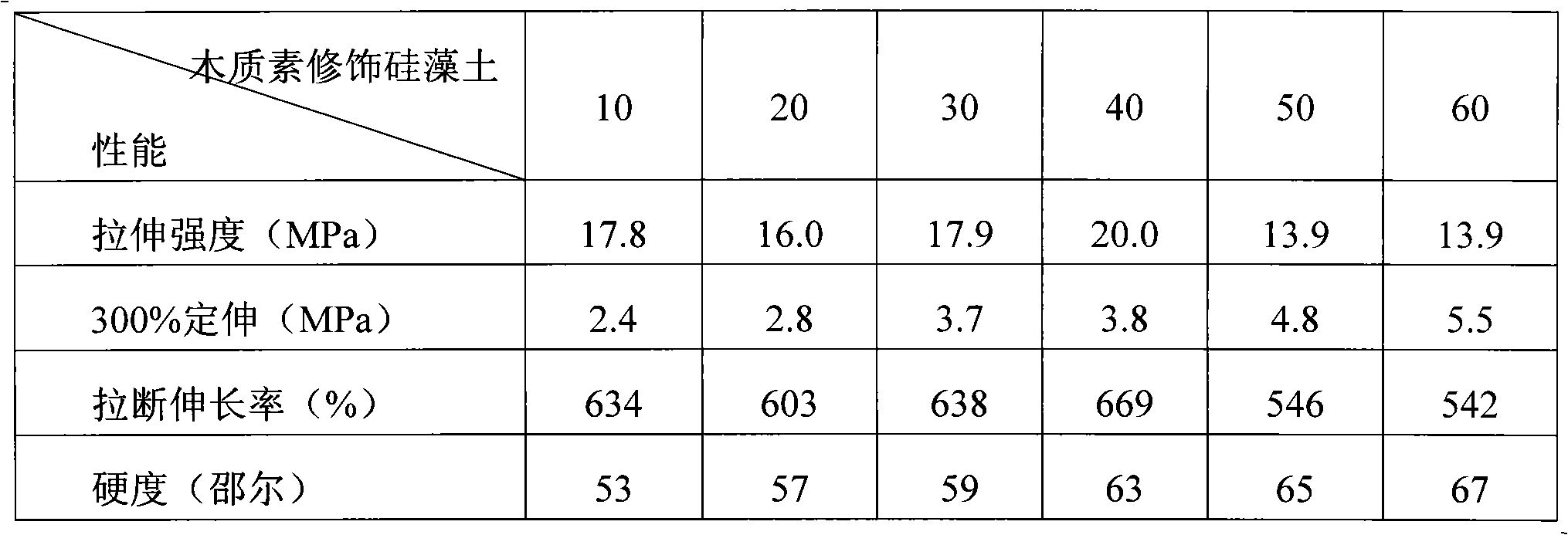

[0016] Add 10 grams of diatomaceous earth and 200 milliliters of deionized water in 1000 milliliters of reactors, stir 24 hours, then add 250 milliliters of papermaking black liquors containing 20% lignin by weight, continue stirring for 24 hours, then add hydrochloric acid to The pH of the slurry is 5-6, suction-filtered, washed repeatedly until the filtrate is close to neutral, and finally dried at 70° C. for 12 hours to obtain 1:5 lignin-modified diatomite for future use.

Embodiment 3

[0018] Add 10 grams of diatomaceous earth and 200 milliliters of deionized water in a 1500 milliliter reaction kettle, stir for 24 hours, then add 450 milliliters of papermaking black liquor containing 20% lignin by weight, continue stirring for 24 hours, then add hydrochloric acid to the slurry pH = 5-6, suction filtration, repeated washing until the filtrate is close to neutral, and finally dried at 70°C for 10 hours to obtain 1:9 lignin-modified diatomite for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com