Ultraviolet irradiation set and ultraviolet irradiation processing unit

A technology of irradiation device and ultraviolet rays, which is applied in the direction of original parts for photomechanical processing, nonlinear optics, and photoplate making process of patterned surface, etc., which can solve the problems of high cost, reduced production volume, and reduced transportation speed of workpiece W , to achieve the effect of reducing cost, increasing production capacity and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

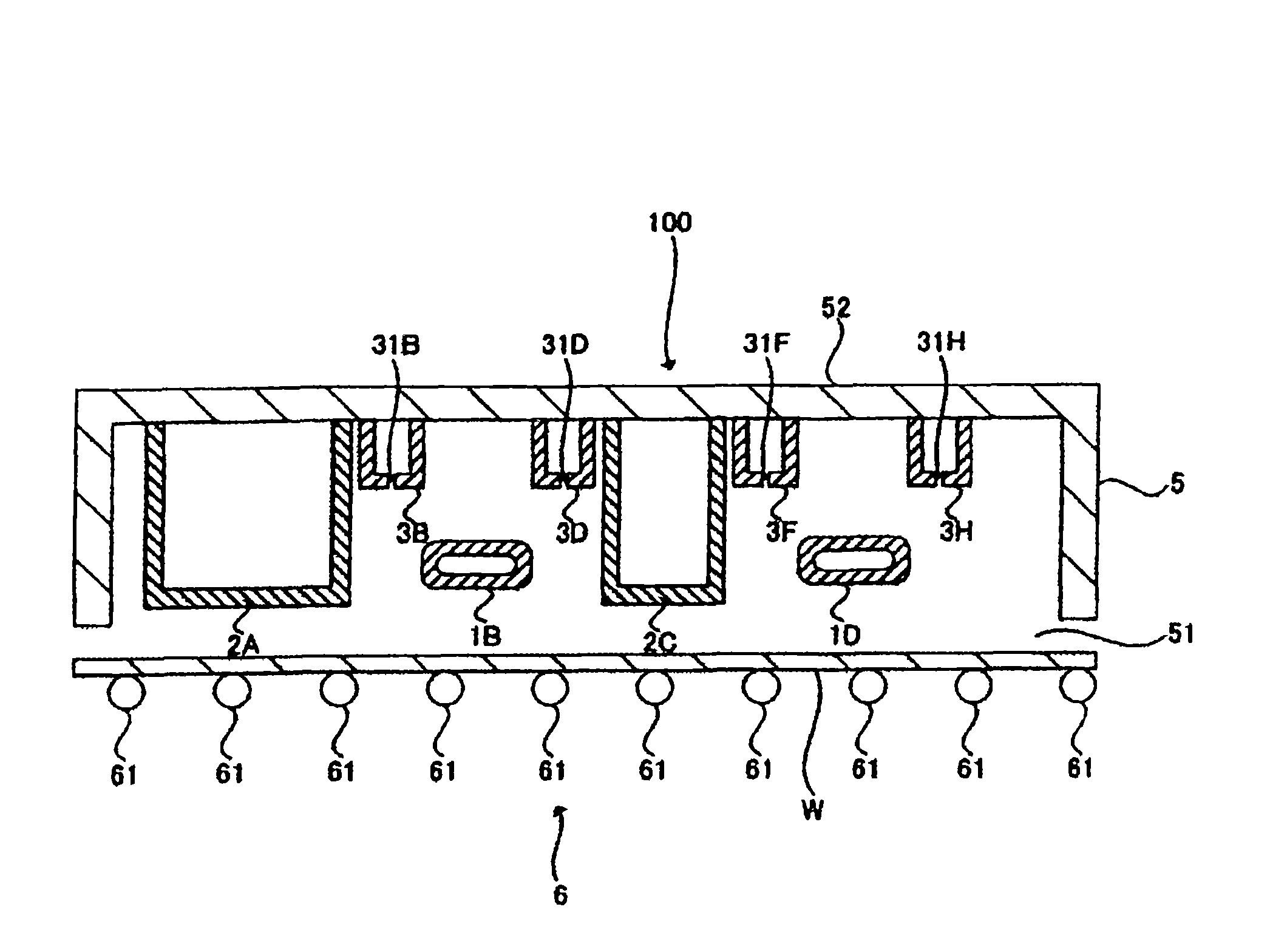

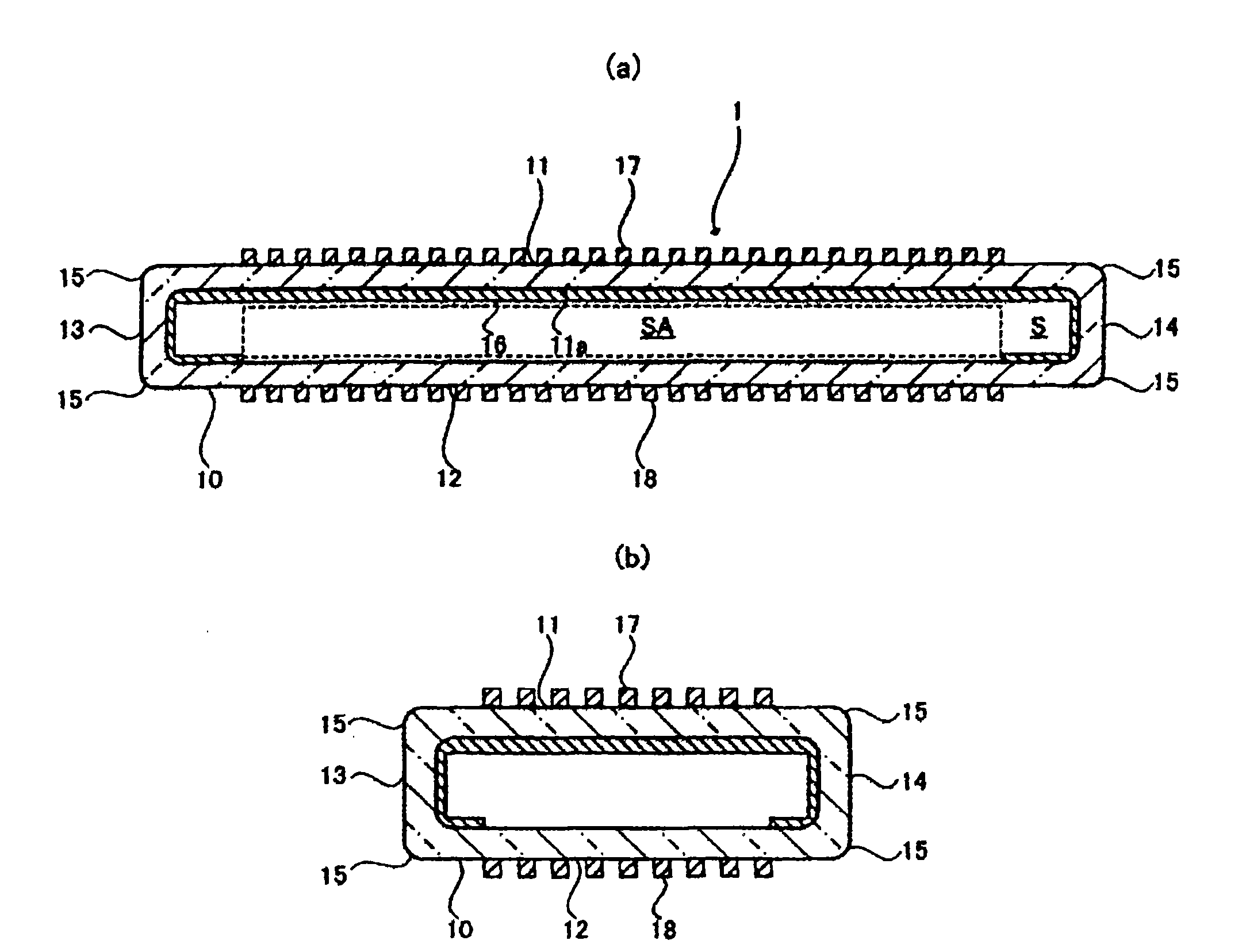

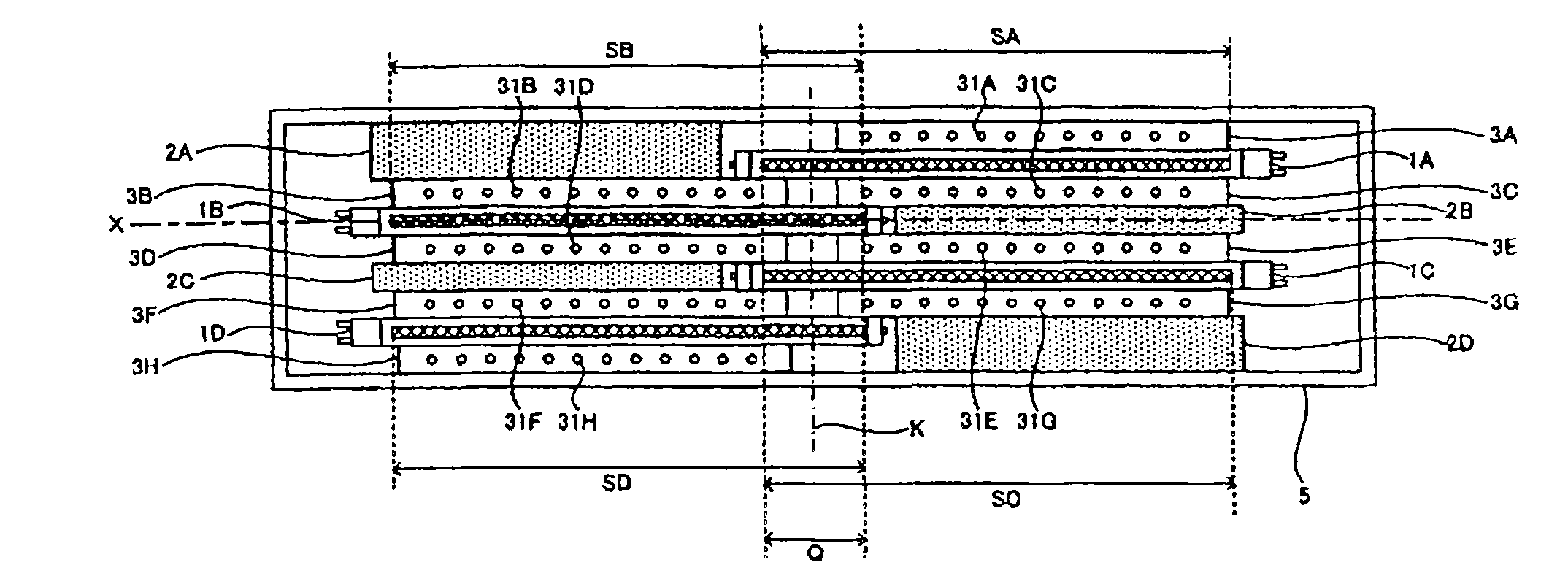

[0057] Hereinafter, for the first embodiment of the ultraviolet irradiation device of the present invention, use Figure 1 to Figure 5 Be explained. figure 1 It is a sectional view showing the structure of the ultraviolet irradiation device of this invention. figure 2 It is a sectional view showing the structure of an excimer lamp. figure 2 (a) shows a cross-sectional view of the excimer lamp cut in the direction of the central axis. figure 2 (b) is a cross-sectional view showing the excimer lamp cut in a direction perpendicular to the central axis. image 3 It is a figure which shows the ultraviolet irradiation apparatus of this invention seeing from a vertical direction. Figure 4 It is a diagram conceptually showing the arrangement of an excimer lamp, a space enclosure, and an object to be processed. Figure 5 It is a figure which shows the structure of a space enclosure.

[0058] The ultraviolet irradiation device 100 is inside a lampshade 5 made of a metal casing...

no. 2 Embodiment approach

[0078] Hereinafter, for the second embodiment of the ultraviolet irradiation device, use Figure 7 to Figure 8 Be explained. This embodiment is preferably applied when the overall length in the direction perpendicular to the conveyance direction of the object to be processed is short. Figure 7 It is a sectional view which shows the structure of 2nd Embodiment of the ultraviolet irradiation apparatus of this invention. Figure 8 Yes means viewing from a vertical direction Figure 7 The diagram when the UV irradiation device is shown. exist Figure 7 , Figure 8 in, with Figure 1 to Figure 5 The same parts are given as Figure 1 to Figure 5 same symbol.

[0079] In the ultraviolet ray irradiation device 200, a plurality of excimer lamps 1A-1C are arranged in parallel in isolation from each other inside the lampshade 5 formed of a metal casing having an opening on the lower side in the vertical direction. There are gas supply pipes 3A to 3F for supplying inert gas such ...

no. 3 Embodiment approach

[0085] Hereinafter, for the third embodiment of the ultraviolet irradiation device of the present invention, use Figure 9 to Figure 11 Be explained. Figure 9 is a cross-sectional view showing the ultraviolet irradiation device. Figure 10 It is a perspective view showing a part of the ultraviolet irradiation device viewed obliquely from above. Figure 9 , Figure 10 in, with Figure 1 to Figure 5 Common parts given with Figure 1 to Figure 5 same symbol. Figure 11 It is a figure for demonstrating the structure of the support body of an excimer lamp. Figure 12 It is a perspective view for explaining the intermittent lighting.

[0086] In the ultraviolet irradiation device 300, the specifications of the lampshade 5 are unified into multiple types. Regardless of the size of the object W to be processed, when processing a variety of objects W to be processed, the lampshade 5 is generally used in common. The number of excimer lamps 1 housed in the lampshade 5 is determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com