Magnesium alloy anode material for water activated batteries and manufacture method thereof

A technology for anode materials and magnesium alloys, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as few reports, achieve good discharge effect, low production cost, and extensive industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Pure magnesium (Mg>99.8%), alloying elements aluminum (Al>99.9%) and gallium (Ga>99.9%) are made into an alloy according to the composition ratio: Al: 1%, Ga4%, Mg95%. First melt magnesium in a crucible made of low-carbon steel at a melting temperature of 750°C. After the magnesium is completely melted, add alloy components aluminum and gallium. After the aluminum and gallium are melted, stir the melt for 10 minutes and then let it stand After 10 minutes, it is poured into a steel mold to obtain a magnesium alloy anode material ingot.

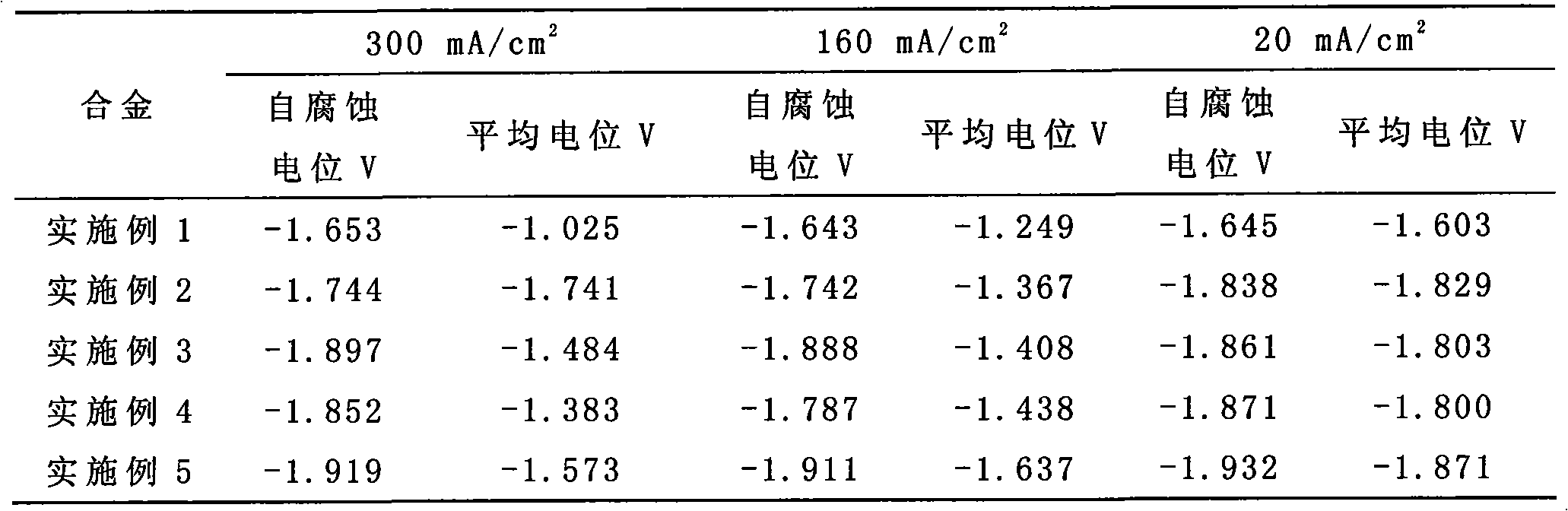

[0026] The magnesium alloy anode material ingot was annealed at 350°C for 24 hours, so that the alloy components could diffuse evenly at high temperature. The uniformly diffused magnesium alloy ingot is preheated to 320°C, the extrusion die is heated to 400°C, and then extruded to obtain a profile. This profile can be used as a water-activated battery material, and its discharge performance is shown in Table 1.

Embodiment 2

[0028] Made of pure magnesium (Mg>99.8%), alloying elements aluminum (Al>99.9%), gallium (Ga>99.9%), according to the composition ratio: Al: 7%, Ga0.5%, Mg92.5%, made alloy. First melt magnesium in a crucible made of low-carbon steel at a melting temperature of 750°C. After the magnesium is completely melted, add alloy components aluminum and gallium. After the aluminum and gallium are melted, stir the melt for 40 minutes and then let it stand After 40 minutes, it was poured into a steel mold to obtain a magnesium alloy anode material ingot.

[0029] The magnesium alloy anode material ingot was annealed at 450°C for 12 hours to make the alloy components diffuse evenly at high temperature. The uniformly diffused magnesium alloy ingot is extruded. During extrusion, the cast billet is preheated to 400°C, the mold is heated to 500°C, and then extruded to obtain a profile. This profile can also be used as a water-activated battery, and its discharge performance is shown in Table...

Embodiment 3

[0031] Pure magnesium (Mg > 99.8%), alloy elements aluminum (Al > 99.9%), gallium (Ga > 99.9%), according to the composition ratio: Al: 6%, Ga2%, Mg92%, made into an alloy. First melt magnesium in a crucible made of low-carbon steel at a melting temperature of 750°C. After the magnesium is completely melted, add alloy components aluminum and gallium. After the aluminum and gallium are melted, stir the melt for 30 minutes and then let it stand After 30 minutes, it was poured into a steel mold to obtain a magnesium alloy anode material ingot.

[0032]The ingot of magnesium alloy anode material was annealed at 400°C for 24 hours, so that the alloy components could be diffused evenly at high temperature. The uniformly diffused magnesium alloy ingot is rolled. When rolling, preheat the cast ingot to 400°C in an electric furnace, and then carry out hot rolling while it is hot. The deformation of each pass of rolling does not exceed 35%. After one pass of rolling, the alloy material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com