Current-driven symmetric magnetic multilayer-structure microwave oscillator

A microwave oscillator and multi-layer structure technology, applied in solid-state lasers and other directions, can solve the problems of unguaranteed device performance consistency and difficult control of included angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

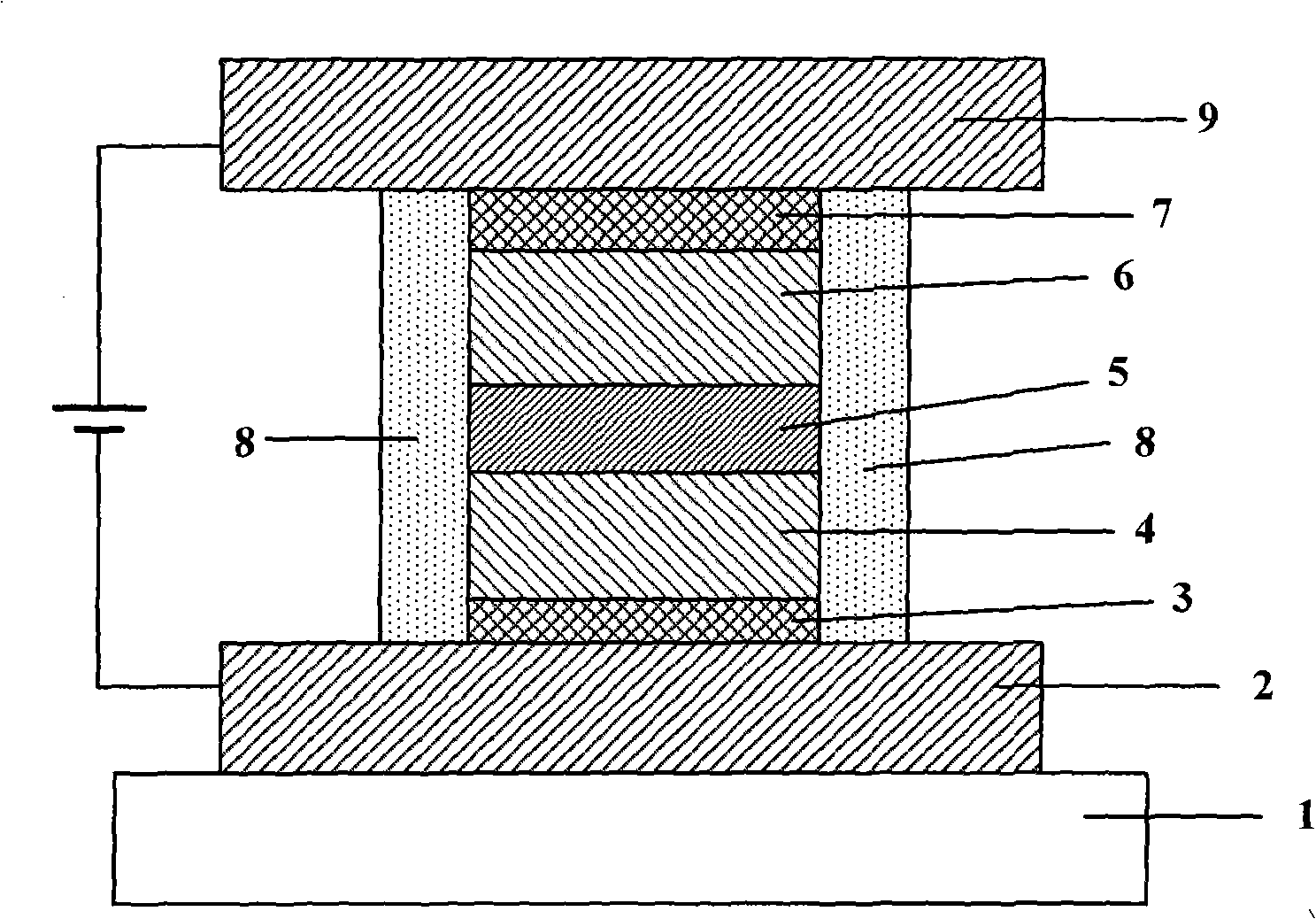

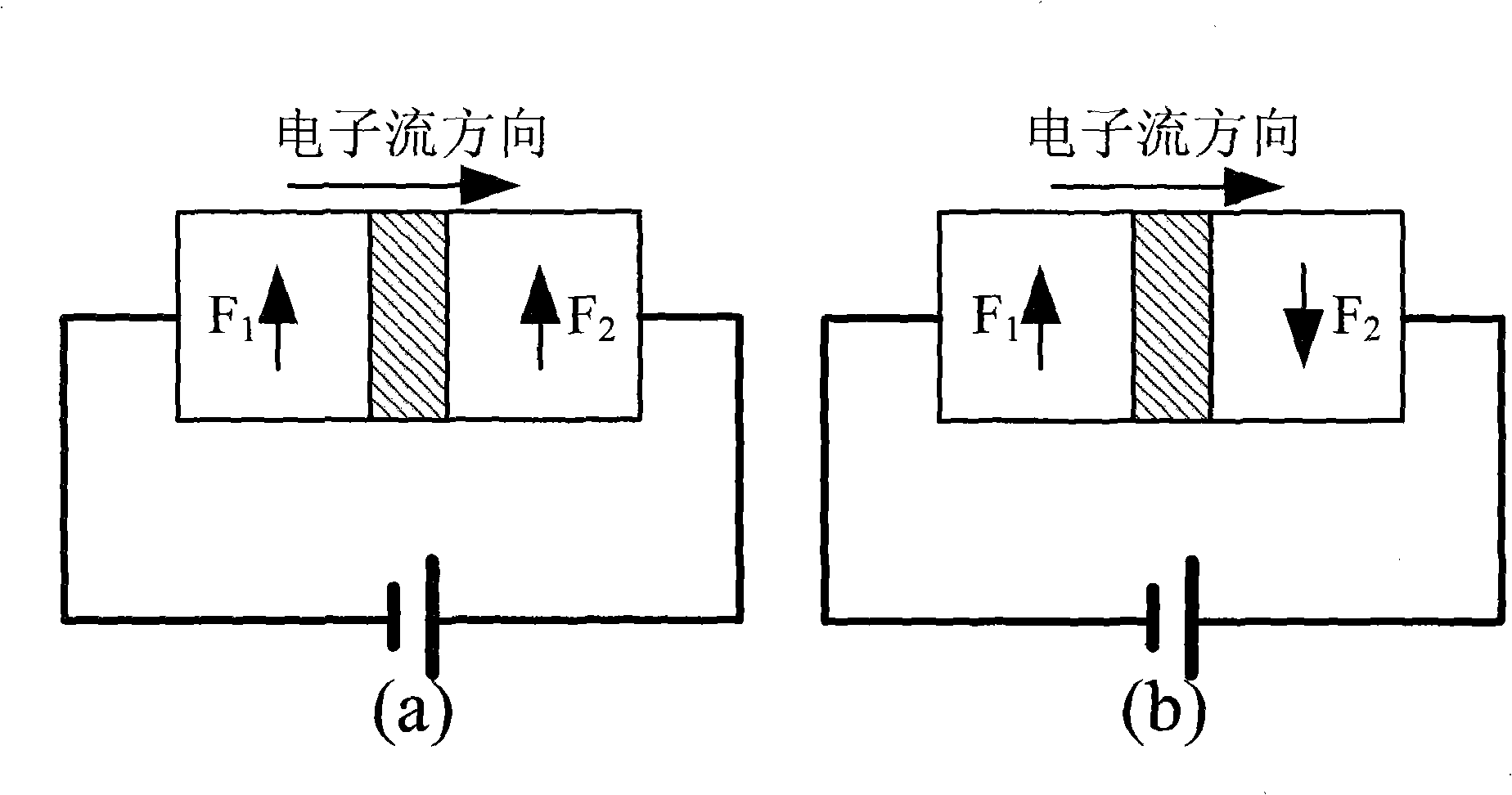

[0020] figure 1 Shown is a schematic diagram of the structure of a current-driven symmetrical magnetic multilayer structure microwave oscillator. The structure is that the bottom electrode layer 2 is deposited on the silicon oxide substrate 1 first. Magnetron sputtering is then used to grow sequentially: a seed layer 3 , a first ferromagnetic layer 4 , an isolation layer 5 , a second ferromagnetic layer 6 , and a protective layer 7 . During the growth process, the induced magnetic fields applied to the first ferromagnetic layer 4 and the second ferromagnetic layer 6 are parallel to each other, and the two layers have the same thickness. The bottom electrode pattern is made by photolithography and etching technology, and then the multi-layer film structure is processed into a columnar structure with a lateral size of about 100 nanometers by electron beam exposure and ion beam etching, and the photoresist is retained. An insulating layer 8 is grown around the nanocolumns by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com