Photosensitive resin composition, photosensitive film, and method for formation of pattern

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of poor resin storage stability, toxicity of acrylate, inability to be precise in addition reaction, etc., and achieve excellent thermal decomposition property and less shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

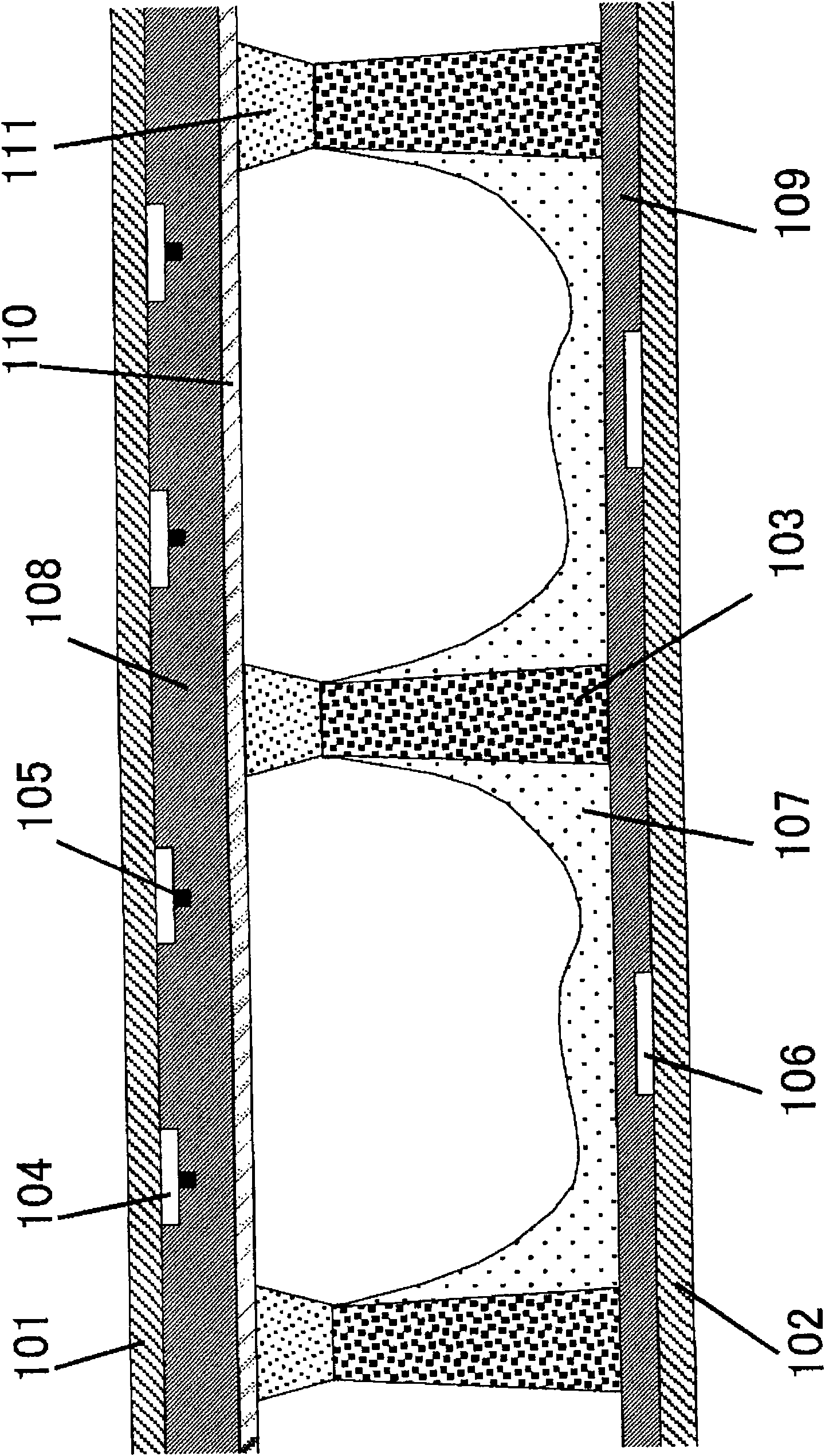

[0204] [Evaluation method of pattern after development (Examples 1-12, Comparative Examples 1-7)]

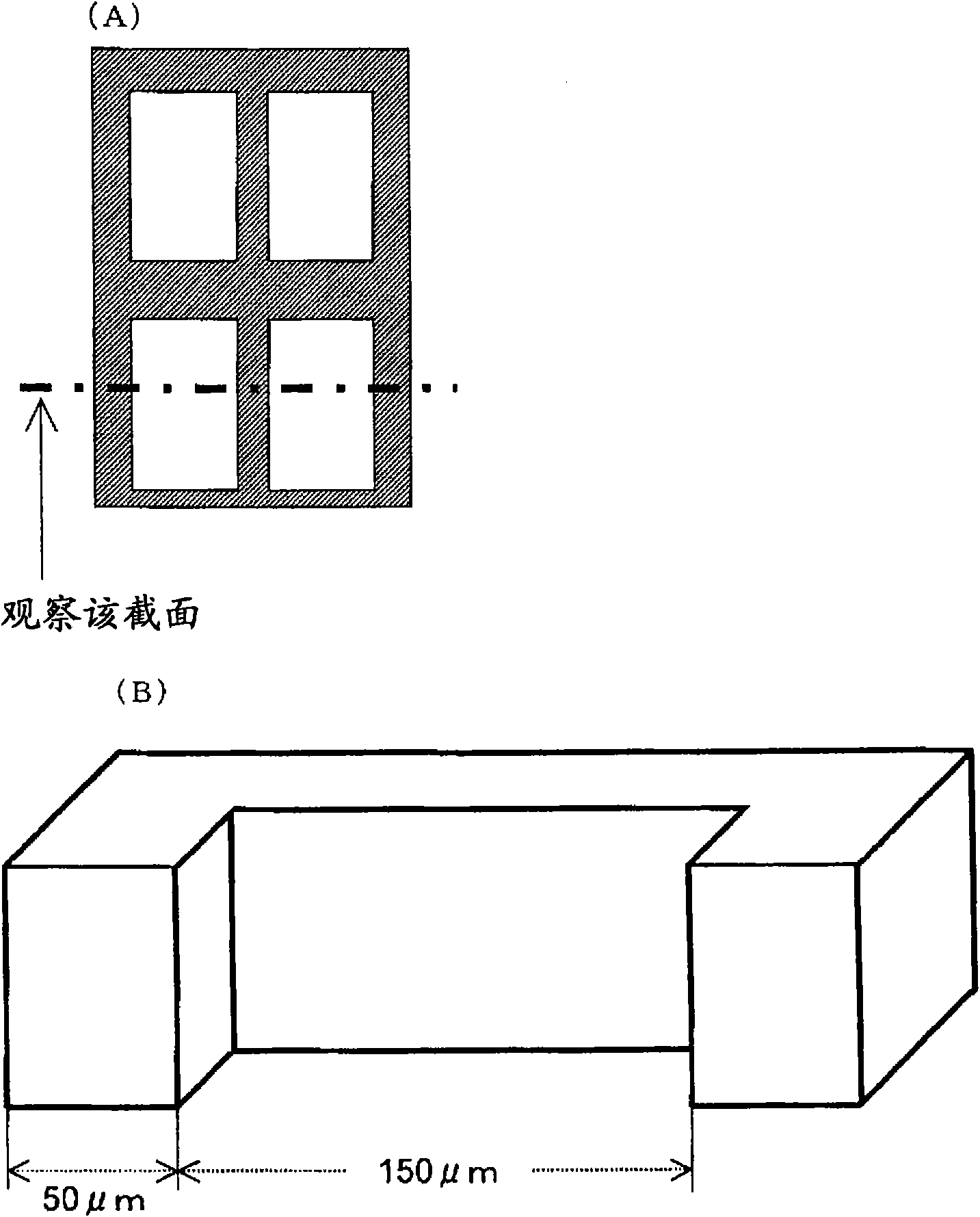

[0205] The developed panel test piece (150 mm x 150 mm x 2.8 mm) was cut and observed with a scanning electron microscope (manufactured by Hitachi, Ltd. "S4200") figure 2 The cross-section of the pattern at the indicated position was measured, and the width and height of the pattern were measured, and evaluated according to the following criteria, respectively. Required specifications are a pattern width of 50 μm, a height of 180 μm, and a spacing of 200 μm.

[0206] A: Within ±3 μm of the required specification.

[0207] B: Exceeding the required specification by ±3 μm and within ±5 μm.

[0208] C: Exceeds the required specification by ±5 μm and is within ±10 μm.

[0209] D: Exceeds the required specification by ±10 µm.

[0210] [Evaluation method of pattern after sintering (Examples 1-12, Comparative Examples 1-7)]

[0211] The sintered panel test piece (150mm×150mm×2.8m...

Synthetic example A1

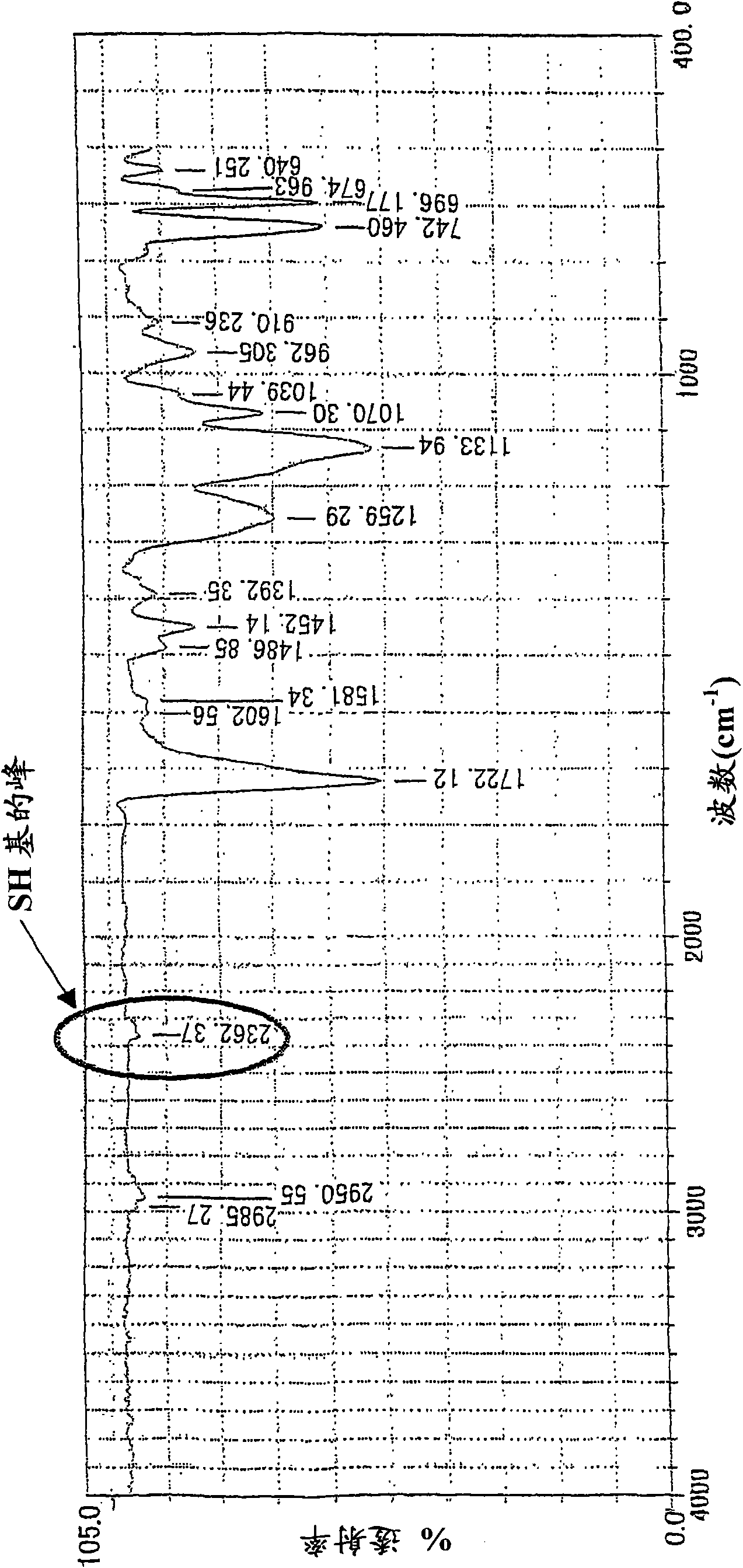

[0236] 55g of benzyl methacrylate, 45g of 2-methacryloxyethyl phthalate, 1g of azobisisobutyronitrile (AIBN), 5g of tetrakis(3-mercaptopropionic acid)pentaerythritol ester (Sakai Chemical Industry Co., Ltd. Co., Ltd.) was added into an autoclave with a stirrer, and stirred in 150 parts of propylene glycol monomethyl ether until uniform under a nitrogen atmosphere. Then polymerize at 80°C for 4 hours, then continue to carry out the polymerization reaction at 100°C for 1 hour, and then cool to room temperature to obtain a methacrylic resin (A1) with SH groups (hereinafter also referred to as "SH group-containing Methacrylic Resin (A1)"). The polymerization ratio of the SH group-containing methacrylic resin (A1) was 98%, and the weight average molecular weight of the SH group-containing methacrylic resin (A1) was 20000 (Mw / Mn: 1.8). The IR spectrum of the obtained resin is as image 3 shown.

Synthetic example A2

[0238] Using 5 g of bis(3-mercaptopropionate) tetraethylene glycol ester (manufactured by Sakai Chemical Industry Co., Ltd.) instead of tetrakis(3-mercaptopropionate) pentaerythritol ester, in the same manner as in Synthesis Example A1, a compound having an SH group was obtained. Methacrylic resin (A2) (hereinafter also referred to as "SH group-containing methacrylic resin (A2)"). The polymerization ratio of the SH group-containing methacrylic resin (A2) was 98%, and the weight average molecular weight of the SH group-containing methacrylic resin (A2) was 15000 (Mw / Mn: 1.7).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com