Method for preparing low-reflection glass

A low-reflection and glass technology, which is applied in the field of chemical composition and preparation of low-reflection glass, can solve the problems of inability to reduce light reflectivity, complicated process methods, and increased processing costs, and achieve good technical support, cost reduction, and technological process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

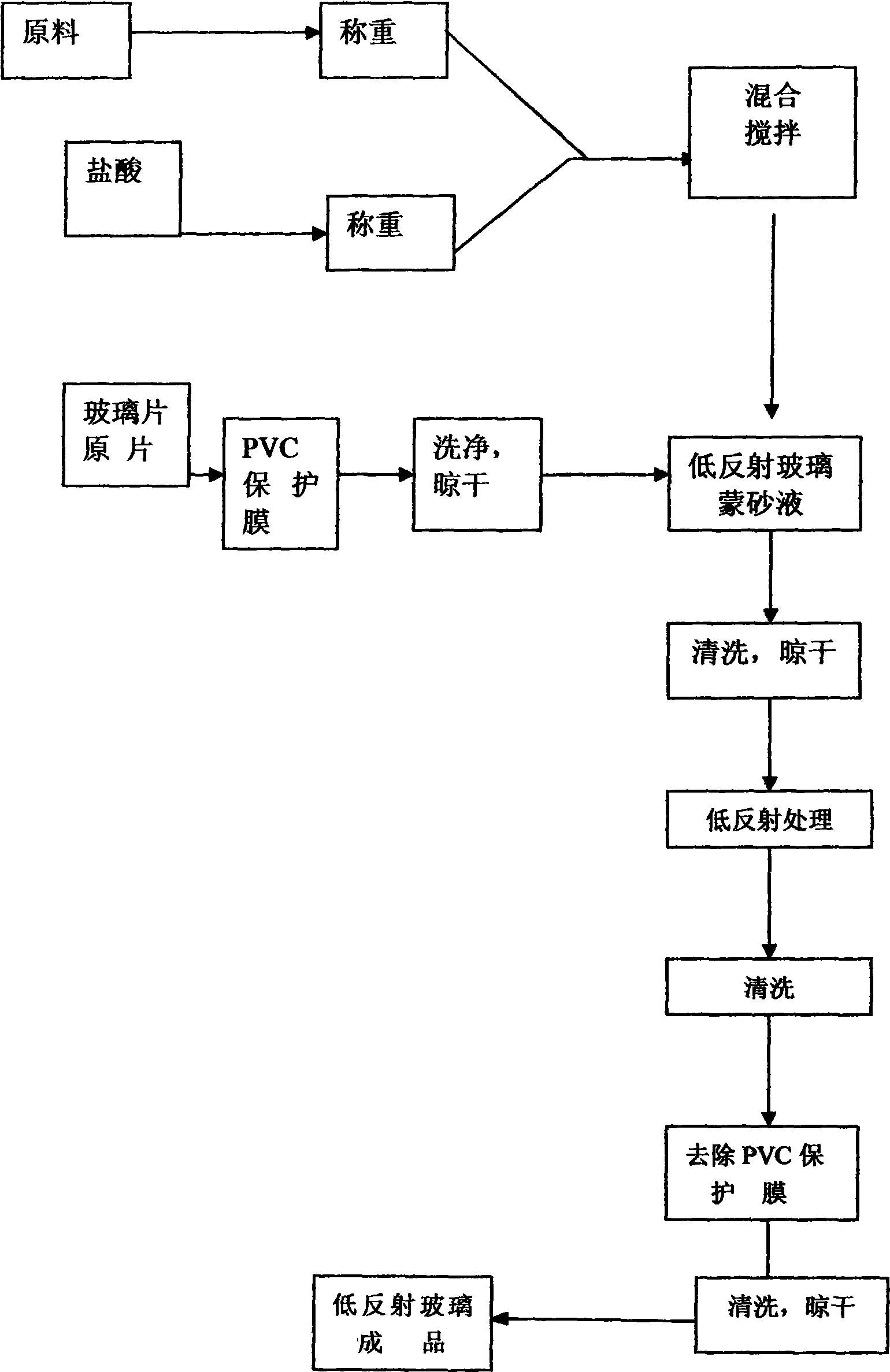

Method used

Image

Examples

Embodiment

[0017] 1. Preparation of materials

[0018] 1. Preparation of low reflection frosting powder (1) (by weight percentage)

[0019] Ammonium bifluoride 50%

[0020] Potassium bifluoride 10%

[0021] Potassium fluoroborate 10%

[0023] Barite Powder 8%

[0024] Kaolin 5%

[0026] Sodium polyacrylate 0.5%

[0027] Hydroxyethyl Cellulose 1.5%

[0028] The inorganic fluorides used in the above-mentioned frosting powder: ammonium hydrogen fluoride, potassium hydrogen fluoride, and potassium fluoroborate can also be used in other inorganic fluorides that can be dissolved in water and produce fluoride ions: ammonium fluoride, sodium hydrogen fluoride, and sodium fluoroborate One or a mixture of several materials can be used instead; similarly, besides calcium fluoride, barite powder, kaolin and barium sulfate, sodium fluorosilicate, calcium fluorosilicate, fluorine One or more mixtures of magnesium silicate, bentonite, an...

example 1

[0060] Prepare 30kg of frosting powder according to the weight ratio of the above compounds: weigh each component and place it in a PVC or plastic container, stir at a constant speed for 10 minutes, and control the temperature in the container not to exceed 30°C. Take out 5kg of evenly stirred frosting powder and place it in a plastic container with a cover, and add 2.5kg of 31% industrial hydrochloric acid (the ratio of powder to hydrochloric acid is 1:0.50). When the hydrochloric acid was just added, the temperature of the mixed solution dropped to 2-3°C, stirred at 30 rpm for 20 hours, the temperature of the mixed solution returned to room temperature, and the aging reaction of the frosting solution was completed. Take a 300×300mm glass sheet with a thickness of 5mm, protect one side with PVC film, clean the other side with glass cleaning solution, rinse with water, and immerse in the above-mentioned mature frosting solution for 20 seconds. Take out the water and wash it, d...

example 2

[0062] The low-reflection glass frosting powder prepared by the chemical composition of Example 1. Take 5.0kg and place it in a plastic container with a cover, add 3.5kg of 36% analytically pure hydrochloric acid (the ratio of powder to hydrochloric acid is 1:0.70), stir for 5 minutes, cover the container, and let the mixed frosting solution react After 24 hours, a uniformly mixed low-reflection glass frosting solution was obtained. Take a 300×300mm flat glass with a thickness of 5mm, protect one side with PVC film, scrub the other side with glass cleaning solution, rinse with water, drip dry, and immerse in low-reflection glass frosting solution for 40 seconds. Take out the reacted glass piece and wash it with water, after dripping dry, immerse it in the glass low-reflection liquid to react for 10 minutes, take it out and wash it with water for 1 minute. After dripping and drying, remove the PVC protective film, wash with water, and dry to obtain a low-reflection glass with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap