Method for preparing liquid fuel oil by catalyzing and cracking triglyceride

A triglyceride, catalytic cracking technology, applied in catalytic cracking, liquid hydrocarbon mixture preparation, cracking, etc., can solve the problems of easy solidification, non-solidification, and high acid value of cracked oil, so as to avoid carbon formation reaction and reduce the condensation point , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

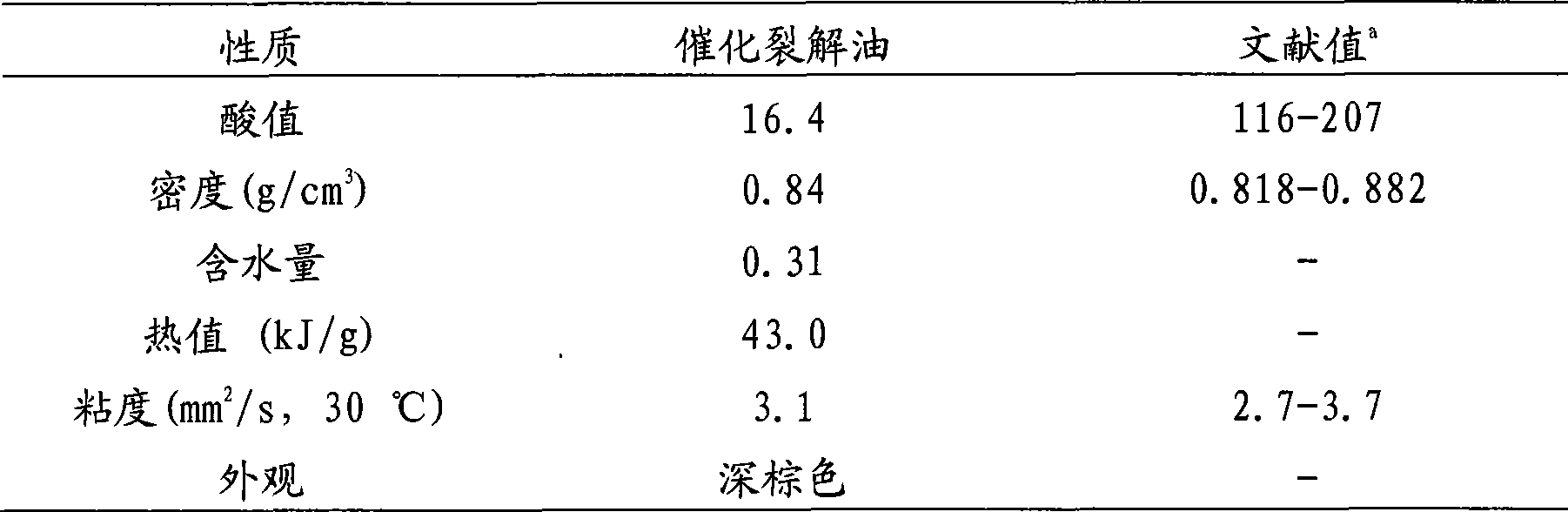

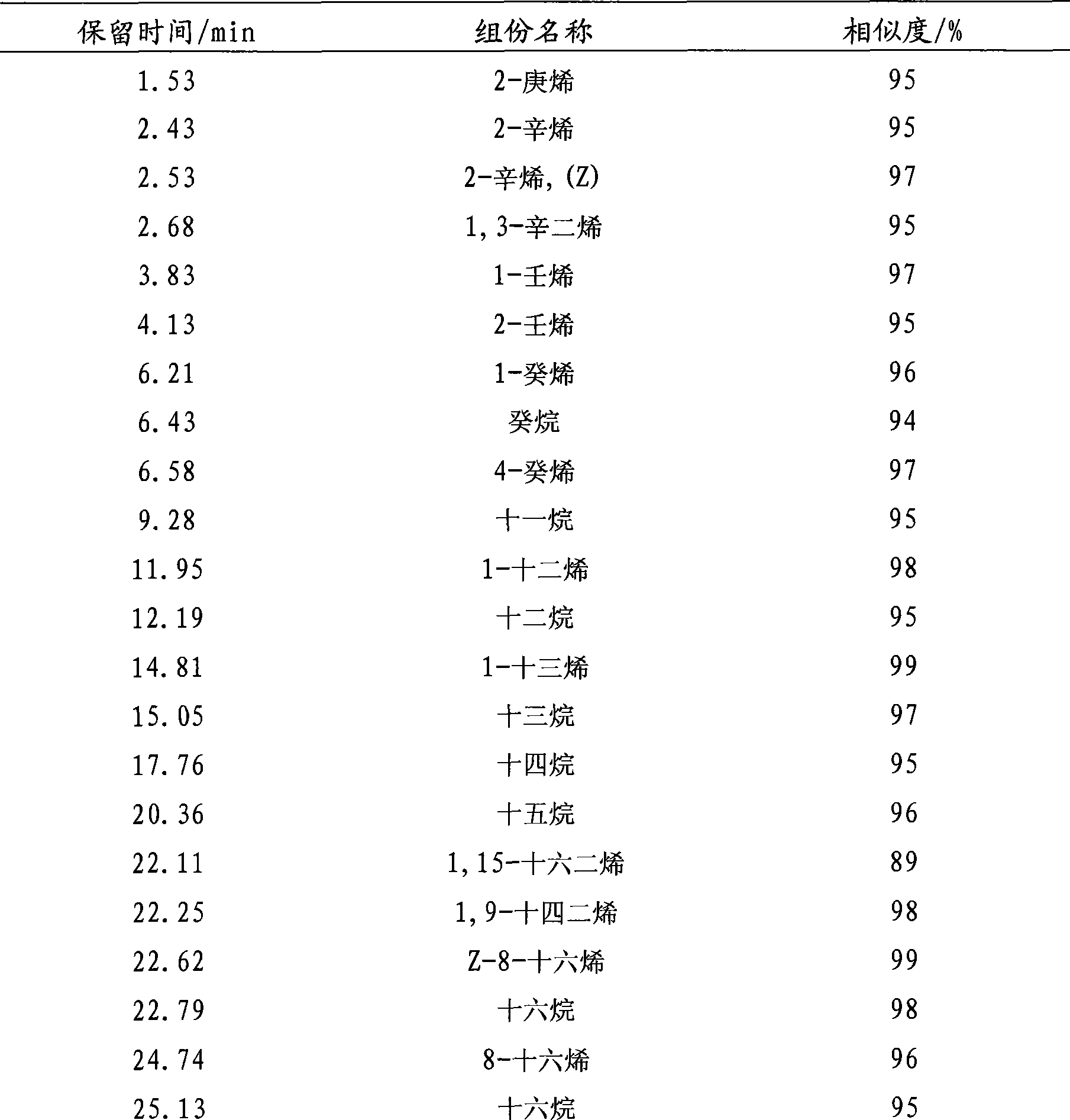

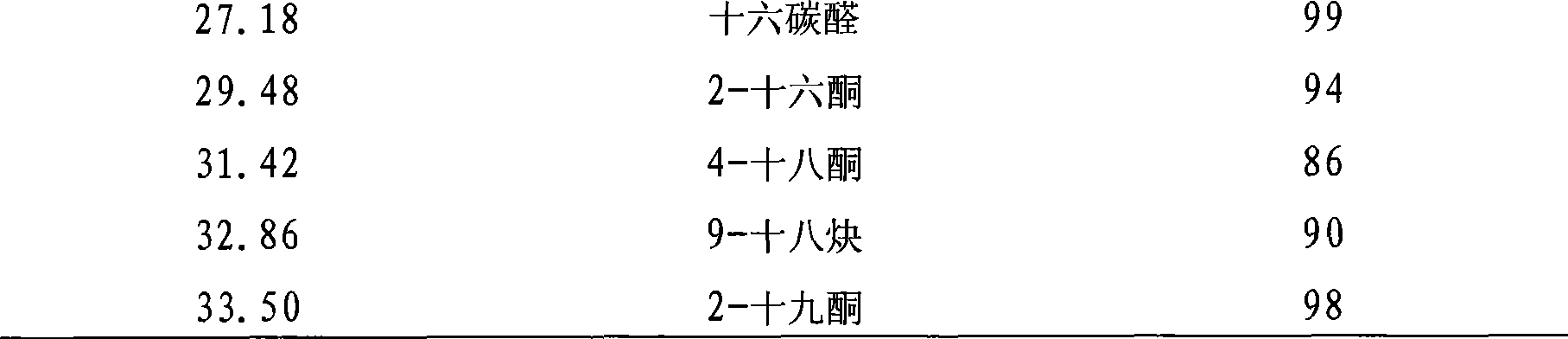

Embodiment 1

[0017] Add 20g of soybean oil and 5g of sodium oxide into a four-necked flask equipped with a mechanical stirrer, a condenser, and a thermometer. When the temperature was raised to 420°C, a condensed liquid appeared. Afterwards, the remaining 80 g of soybean oil was added dropwise, and the dripping was completed within 2 hours. Continue to maintain catalytic cracking at 420°C until no fraction is generated. Catalytic cracking to obtain liquid 71g, residual carbon 5g, non-condensable gas 24g.

Embodiment 2

[0019] Add 20g of rapeseed oil and 5g of sodium oxide into a four-necked flask equipped with a mechanical stirrer, a condenser, and a thermometer. When the temperature was raised to 420°C, a condensed liquid appeared. After that, the remaining 80 g of rapeseed oil was added dropwise, and the dripping was completed within 2 hours. Continue to maintain catalytic cracking at 420°C until no fraction is generated. Catalytic cracking to obtain liquid 73g, residual carbon 6g, non-condensable gas 21g.

Embodiment 3

[0021] Add 20g of gutter oil and 5g of sodium oxide into a four-necked flask equipped with mechanical stirring, a condenser, and a thermometer. When the temperature was raised to 420°C, a condensed liquid appeared. After that, the remaining 80 g of waste oil was added dropwise, and the dripping was completed within 2 hours. Continue to maintain catalytic cracking at 420°C until no fraction is generated. Catalytic cracking to obtain liquid 70g, residual carbon 8g, non-condensable gas 22g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com