Micropore structure of microplate strip

A microporous structure and microporous technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increasing the surface area to volume ratio or solution depth, not suitable for luminescent immunodetection, increasing the reaction rate and light absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment one (enzyme-linked immunoassay test is used):

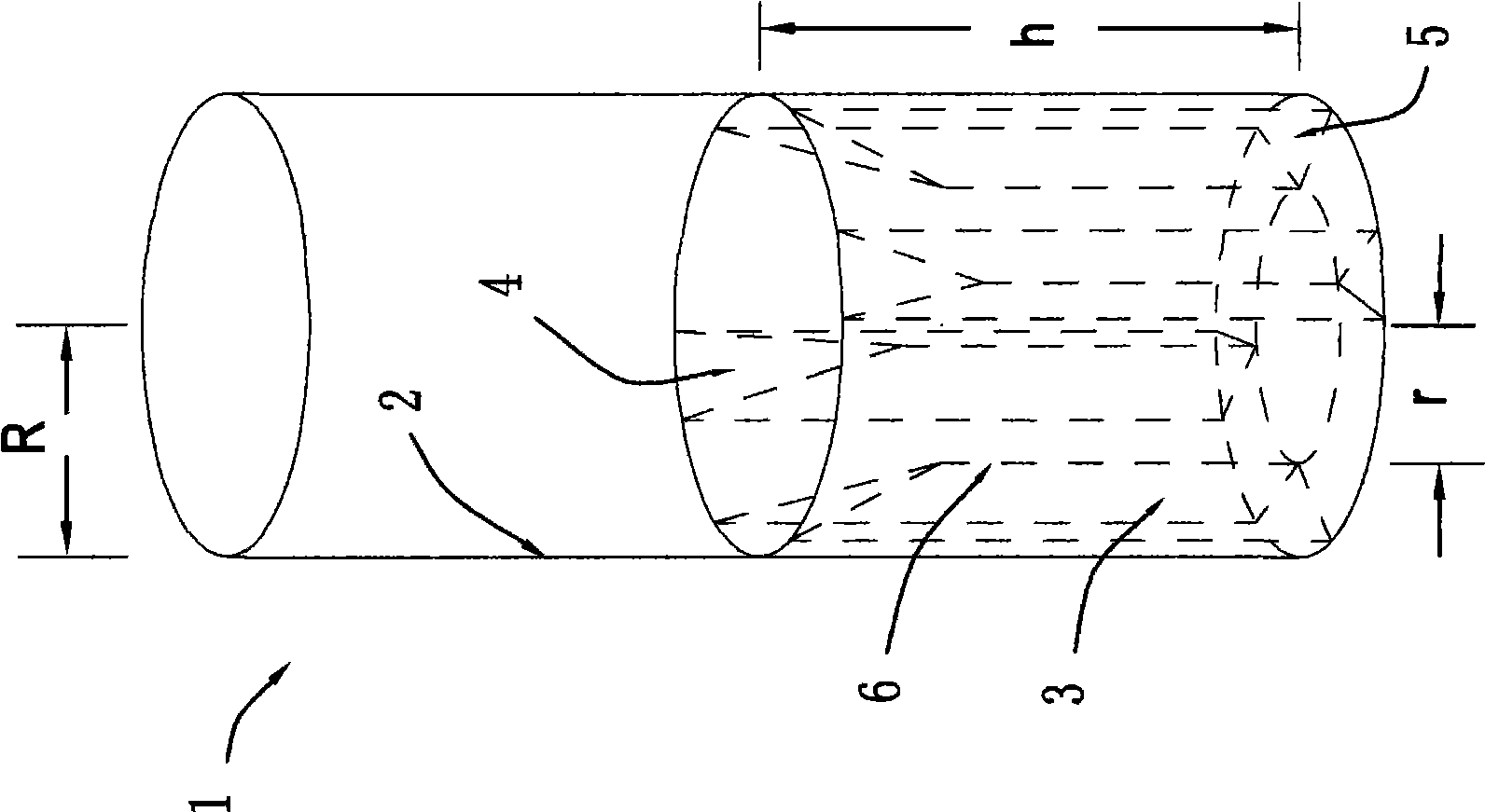

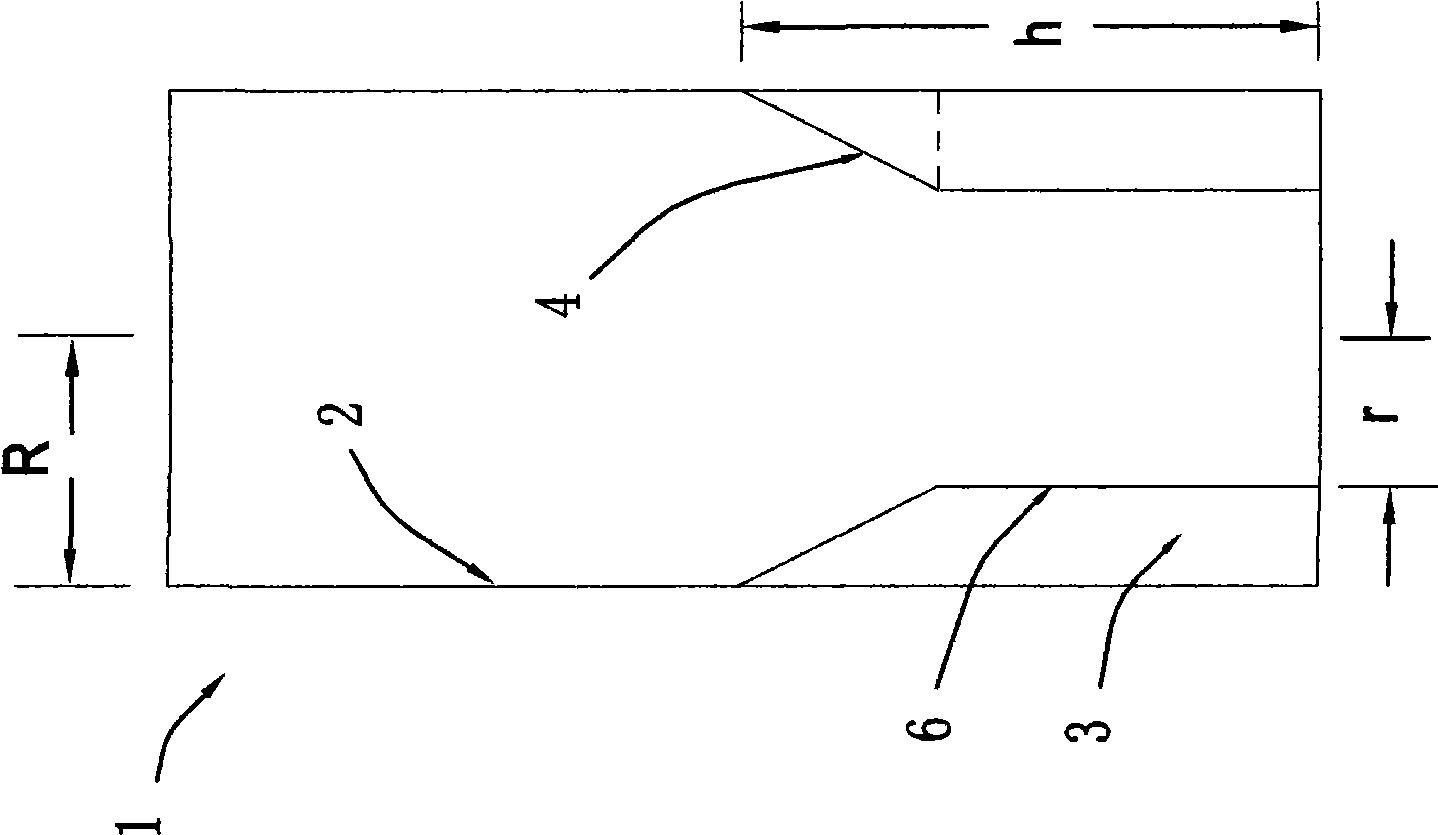

[0024] like figure 1 , figure 2 and Figure 5 The microporous structure of the microporous strip shown contains a circular microhole 1 with a standard height of 12mm and an inner diameter 2R of 6.8mm, on the ring wall 2 of the lower half (ie 6mm height) of the microwell 1 16 convex racks 3 with the same shape and proportion are arranged in equal parts. The convex rack 3 is a triangular prism with an arc surface on one side. The ring wall 2 of 1; the convex rack 3 is integrally formed with the microhole 1, the convex rack 3 is perpendicular to the bottom surface of the microhole 1, the height of the convex rib 6 of the convex rack 3 is 4mm, and the top of the convex rack 3 is an oblique sector 4. The projection formed by the convex rack 3 on the bottom of the microhole 1 is fan-shaped 5, and the distance between the convex rib 6 and the center of the microhole 1 is r=2.2mm.

[0025] The convex rack 3 used i...

Embodiment 2

[0045] Embodiment 2 (for luminescence immunoassay):

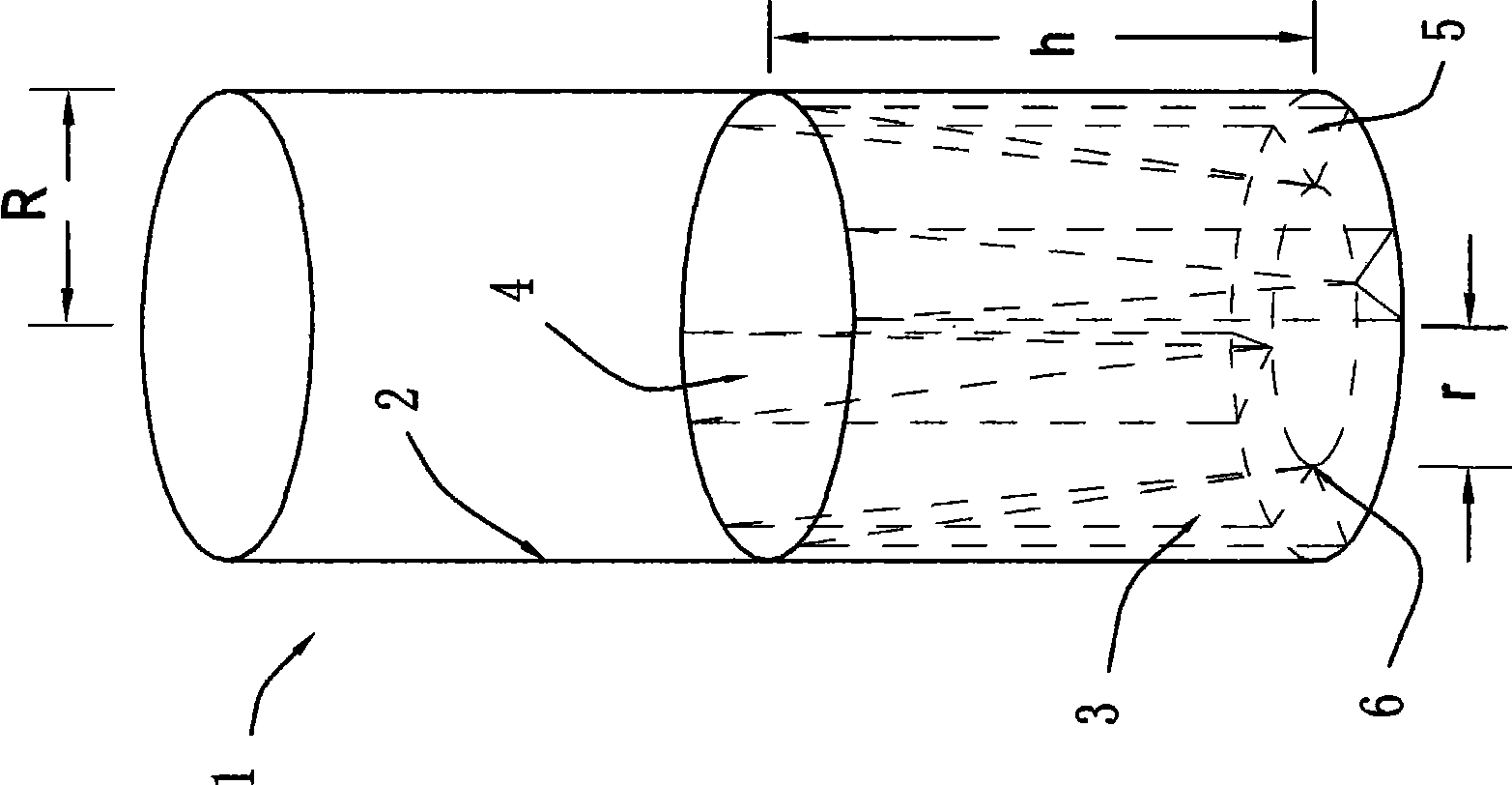

[0046] like image 3 , Figure 4 and Figure 5The microwell structure of the microwell strip shown, the microwell 1 of the microwell strip with convex racks protruding inward for luminescent immunoassay, and the ring wall 2 in the lower half (ie 6mm height) of the microwell 1 16 convex racks 3 with the same shape and proportion are arranged on the upper part. The convex rack 3 is a quadrangular prism with an arc surface. The bottom of the convex rack 3 is connected to the bottom of the microhole 1. The ring wall 2 of the hole 1; the convex rack 3 is integrally formed with the microhole 1, the convex rack 3 is perpendicular to the bottom surface of the microhole 1, the rib of the convex rack 3 is a point, and the distance between the convex rib 6 and the center of the microhole 1 is r =1.5mm, the rib height in this embodiment is 0mm, at this time the convex rack 3 is a quadrangular prism, with an area-to-volume ratio.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com