Brazing method of aluminum electromagnetic wire and brass

A technology of aluminum magnet wire and brazing method, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of low tensile strength, difficult bending and forming, unfavorable winding of transformer coils, etc., to achieve Good high temperature resistance and good temperature change resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

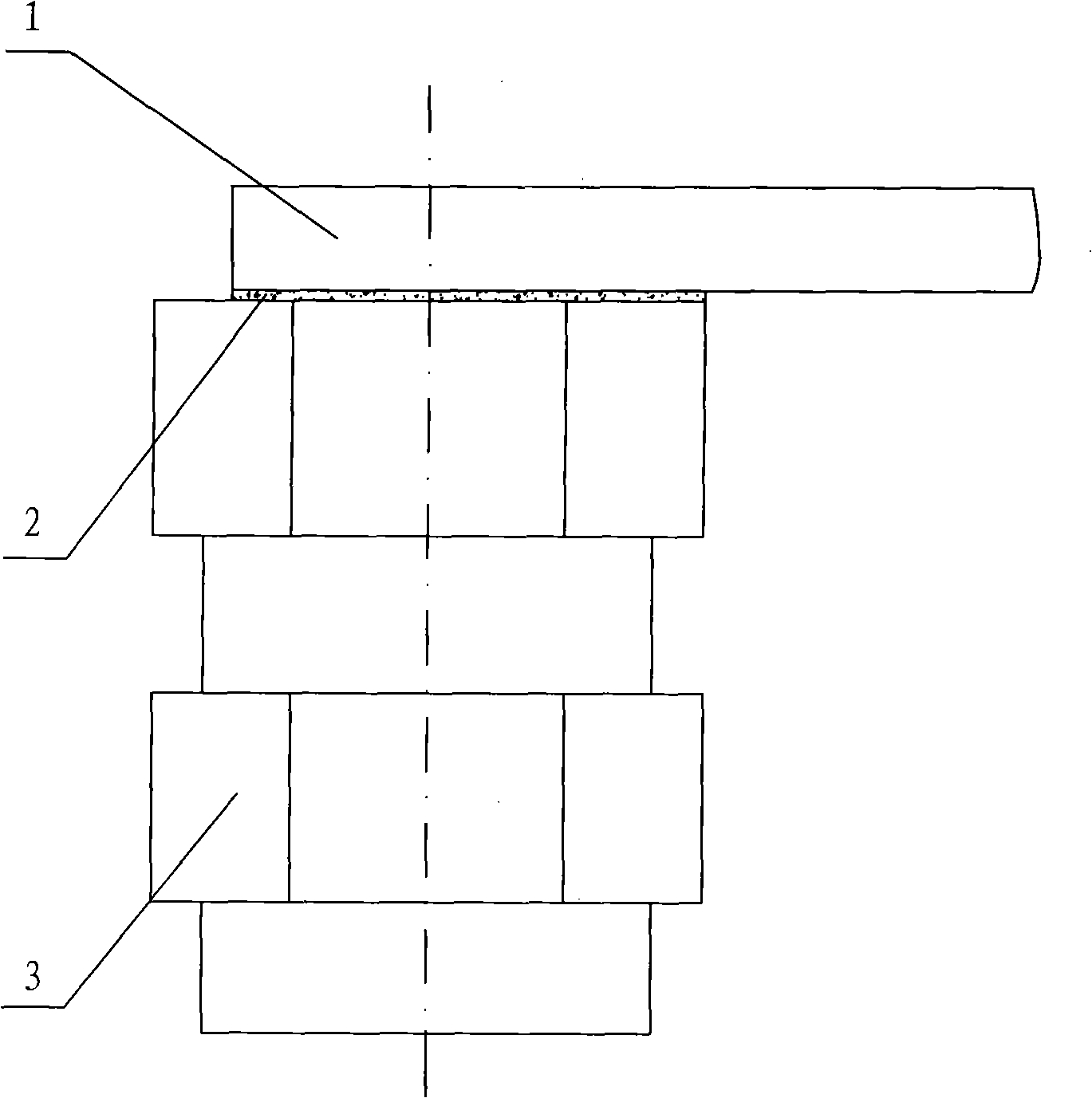

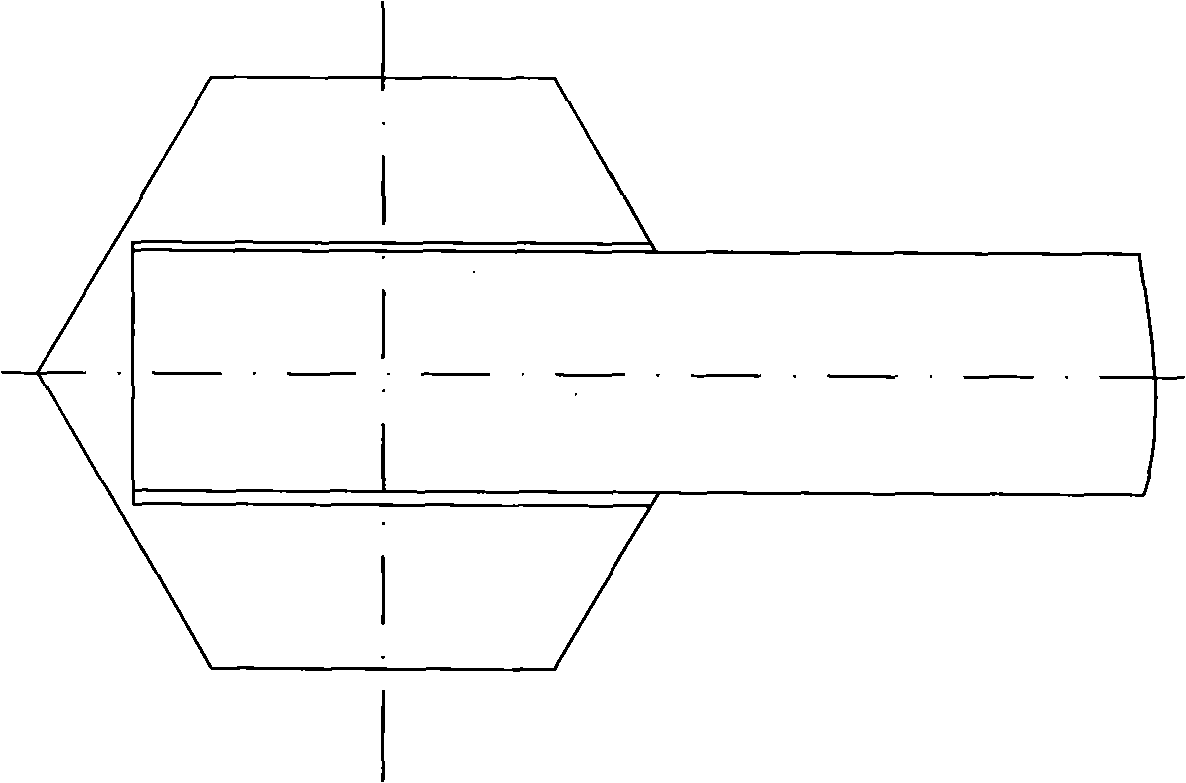

[0015] In the figure, 1 is an aluminum magnet wire, 2 is a welding seam, and 3 is a brass brass connector.

[0016] see Figure 1-2 , the brazing method of aluminum magnet wire and brass, before welding, the surface of the brass connector is electroplated or electroless nickel-plated to enhance the connection strength of the solder and the brass connector and to strengthen the aluminum-copper To improve the corrosion resistance of joints, use flux-cored Al-Si hard solder, the flux core is non-corrosive potassium fluoroaluminate flux, and use flame brazing to bond the aluminum magnet wire and the nickel-plated surface of the brass connector. Brazing.

[0017] The brass connectors go through the following processes in turn: neutral degreasing - ultrasonic degreasing - water washing - pickling - water washing - alkaline copper plating - water washing - a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com