Anti-crocking rubber sole

A rubber sole and anti-blowout technology, which is applied to shoe soles, footwear, material inspection products, etc., can solve the problems of manufacturing process differences, raw material quality fluctuations, rubber aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation method of anti-blooming rubber sole of the present invention comprises the following steps:

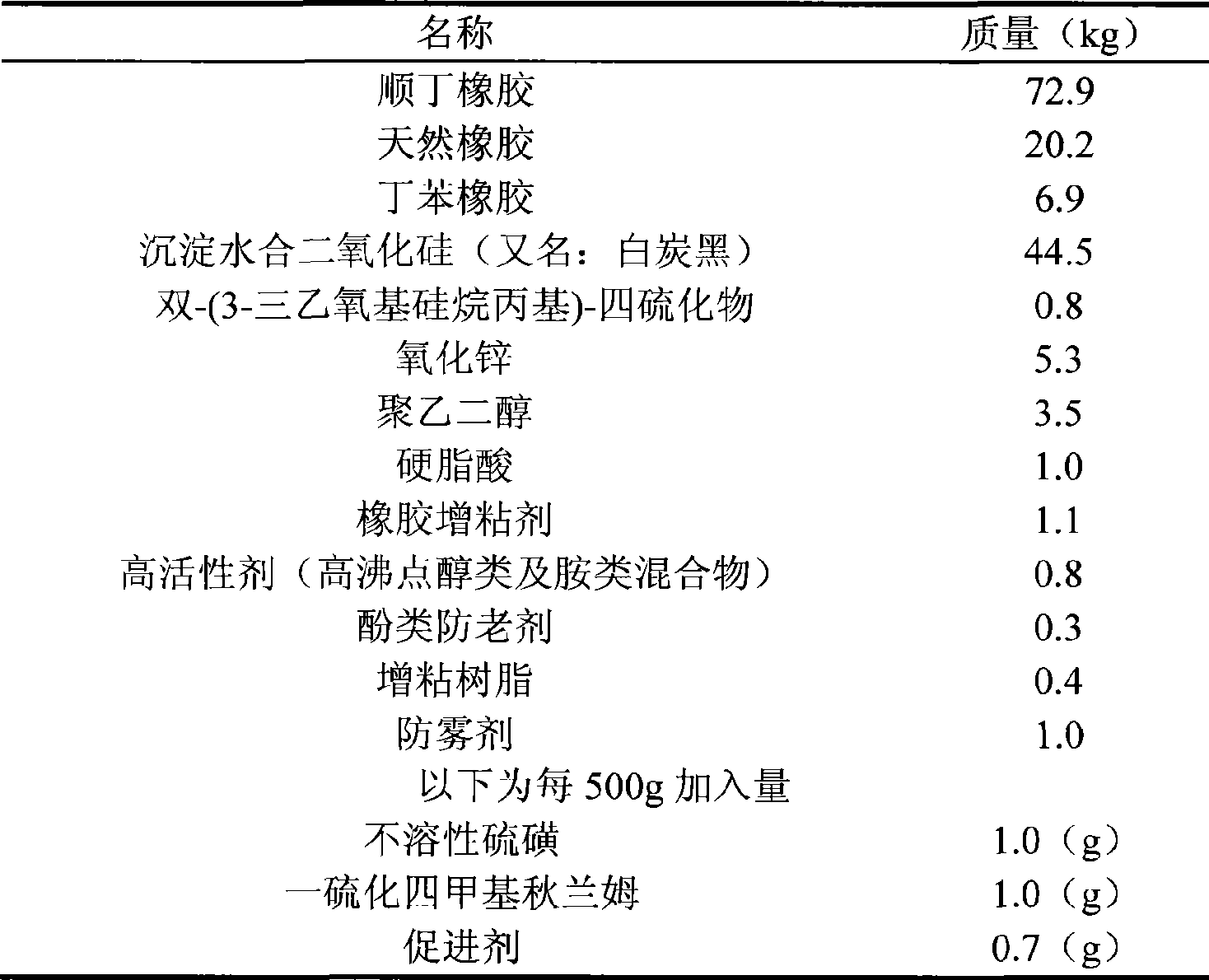

[0042] 1) Material weighing

[0043] Raw material formula is shown in Table 1, wherein, the addition of insoluble sulfur, tetramethylthiuram monosulfide and promotor is according to A part (the raw material composition of A part comprises butadiene rubber, natural rubber, styrene-butadiene rubber, precipitated hydrated two Silicon oxide, bis-(3-triethoxysilylpropyl)-tetrasulfide, zinc oxide, polyethylene glycol, stearic acid, rubber tackifier, active agent, phenolic antioxidant, tackifying resin and Antifogging agent) is calculated as the total mass of 500g.

[0044] Table 1

[0045]

[0046] 2) Banbury

[0047] Mix the rubber and tackifier raw materials, start the banbury mixer to mix the materials evenly, add 2 / 3 of the precipitated hydrated silica, continue banburying, mix the rubber and the precipitated hydrated silica, and re-agglomerate...

Embodiment 2

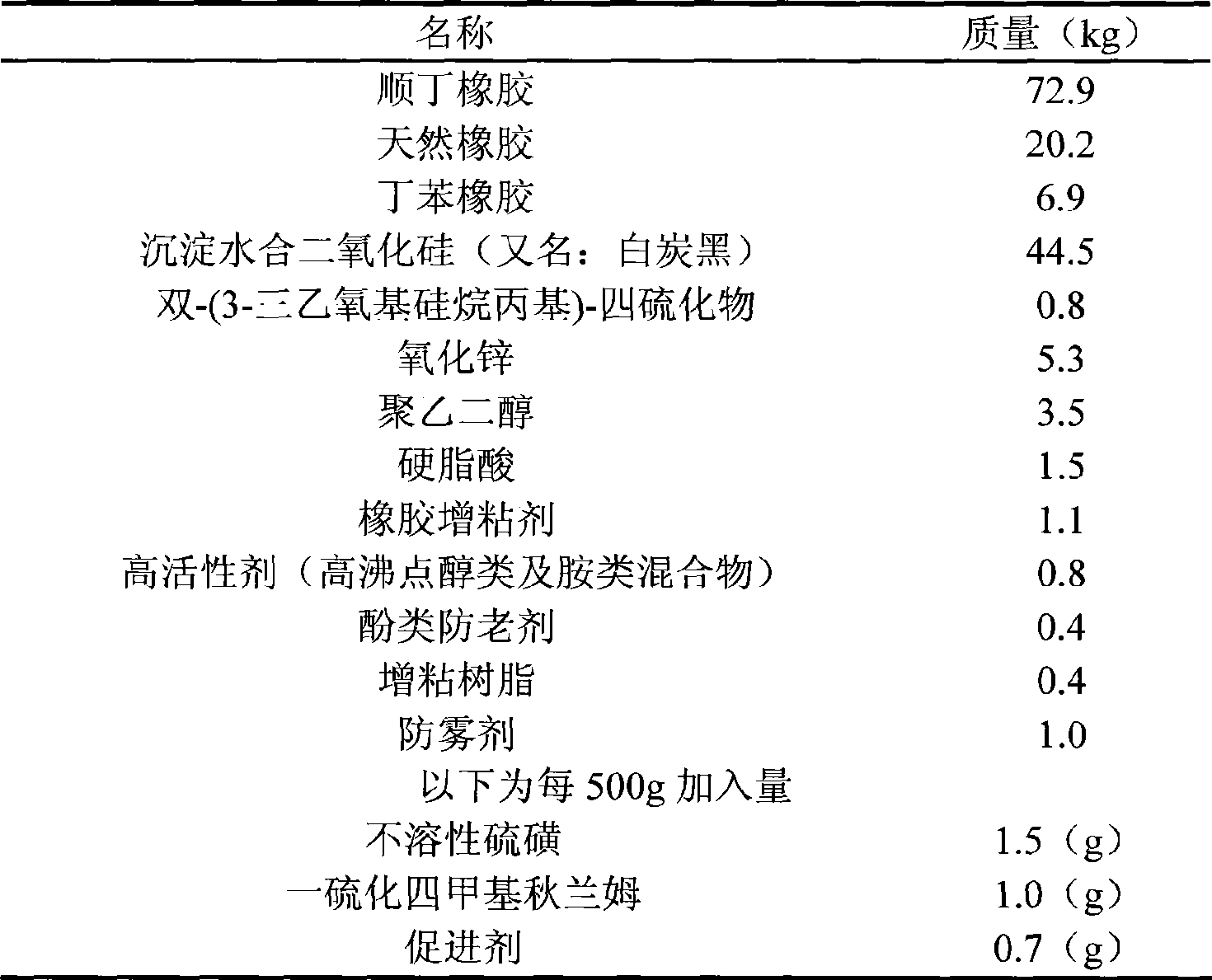

[0056] Embodiment 2: Similar to Embodiment 1, the difference is that the raw material formula is shown in Table 2, the start-up temperature of the internal mixer is 25° C., and the roll distance of the first and second triangular buns is 1 mm.

[0057] Table 2

[0058]

Embodiment 3

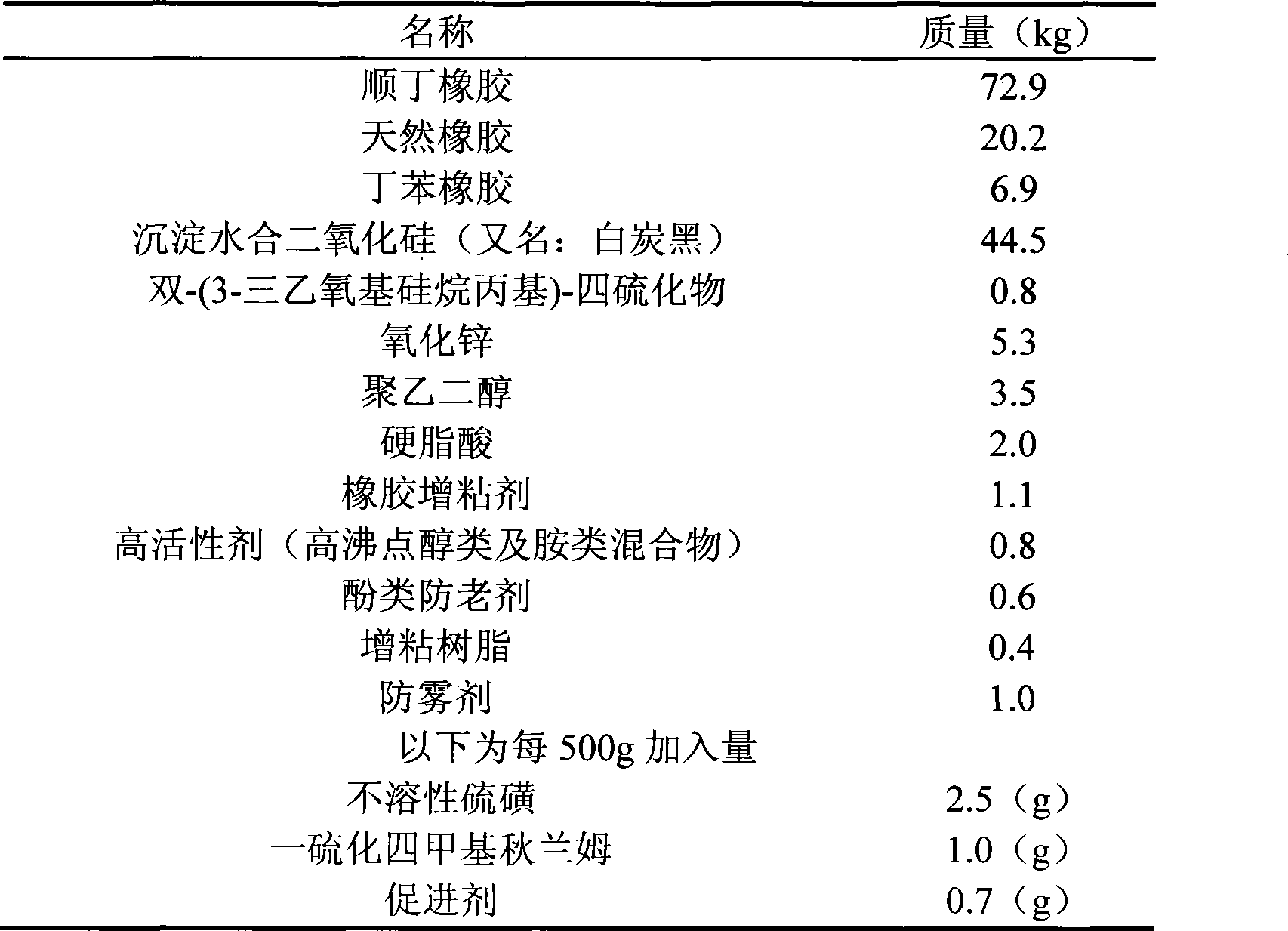

[0059] Embodiment 3: Similar to Embodiment 1, the difference is that the raw material formula is shown in Table 3, and the starting temperature of the internal mixer is 30°C.

[0060] table 3

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com