Aquaculture water purifying agent and preparation method thereof

A technology of aquaculture and purification agent, which is applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc. It can solve the problems of algae cell death, loss of algae purification effect, water quality deterioration, etc., and achieve the promotion of micro-ecology balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

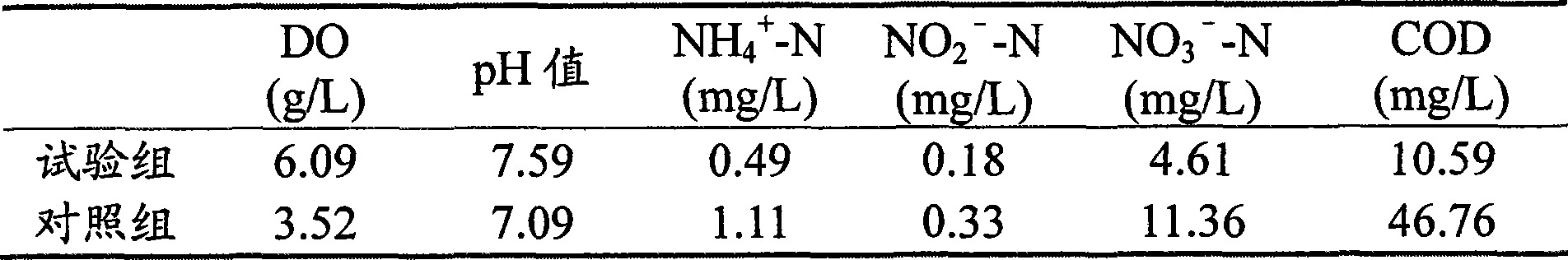

Embodiment 1

[0039] (1) Zeolite modification

[0040] Pour the natural zeolite block into a jaw crusher for crushing, then further grind it with a disc mill, and sieve it with a vibrating sieve to obtain zeolite with different particle sizes, and finally pass it through an 80-mesh sieve for later use. Weigh a certain amount of zeolite passing through an 80-mesh sieve, put it into an oven, and calcine it at a temperature of 250° C. After 5 hours, take it out and put it in a desiccator to cool to room temperature, and seal it for future use.

[0041] (2) Calcination of dolomite

[0042] Pour the natural dolomite minerals into the jaw crusher for crushing, then calcinate at 1600°C for 5 hours to form calcined dolomite, then further grind it with a disc mill, and sieve it with a vibrating sieve to obtain dolomite with different particle sizes, passing through 80 mesh Sift for later use.

[0043] (3) Preparation of tourmaline particles

[0044] Pour the natural magnesium tourmaline mineral i...

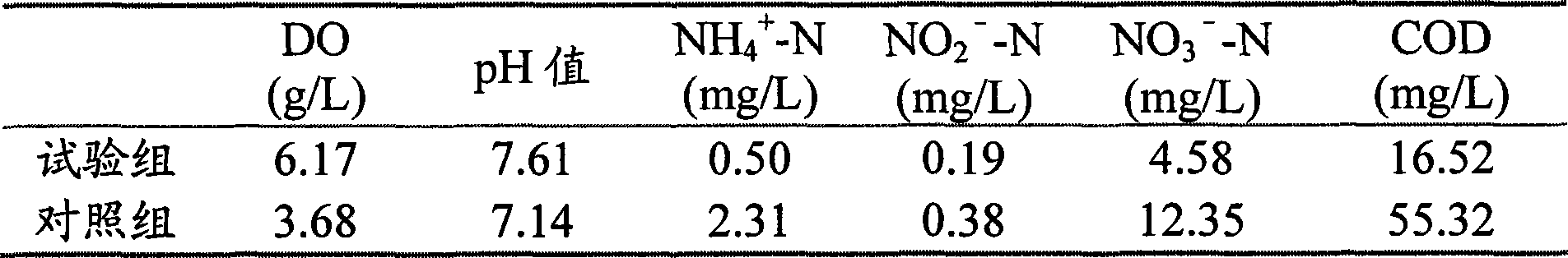

Embodiment 2

[0048] (1) Zeolite modification

[0049] Pour the natural zeolite block into a jaw crusher for crushing, then further grind it with a disc mill, and sieve it with a vibrating sieve to obtain zeolite with different particle sizes, and finally pass through a 2000-mesh sieve for later use. Weigh a certain amount of zeolite passing through a 2000-mesh sieve, put it into an oven, and calcine it at a temperature of 800 ° C. After 2 hours, take it out and put it in a desiccator to cool to room temperature, and seal it for future use.

[0050] (2) Calcination of dolomite

[0051] Pour natural dolomite minerals into a jaw crusher for crushing, then calcinate at 700°C for 1.5 hours to form calcined dolomite, then use a disc mill to further grind it, and sieve it with a vibrating sieve to obtain dolomite with different particle sizes. After the mesh sieve, it is ready for use.

[0052] (3) Preparation of tourmaline particles

[0053] Pour natural magnesium tourmaline particulate miner...

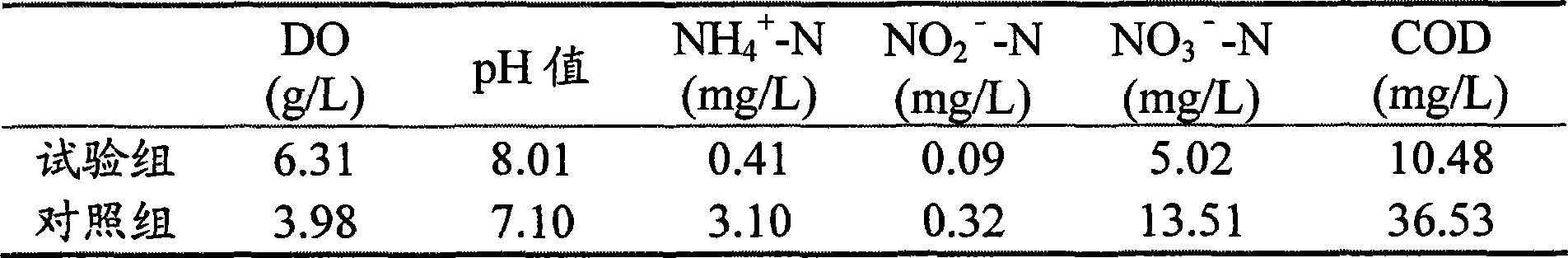

Embodiment 3

[0057] (1) Zeolite modification

[0058] Pour the natural zeolite block into a jaw crusher for crushing, then further grind it with a disc mill, and sieve it with a vibrating sieve to obtain zeolite with different particle sizes, and finally pass it through a 1800-mesh sieve for later use. Prepare a hydrochloric acid solution with a concentration of 20 mol / L at room temperature, weigh a certain quality of 1800 mesh zeolite with a liquid-solid ratio of 3:1, soak it in the prepared 20 mol / L hydrochloric acid solution and stir for 1 hour at a constant speed. After standing for 5 hours, filter, wash, dry, and place in a desiccator for later use.

[0059] (2) Calcination of dolomite

[0060] Pour natural dolomite minerals into a jaw crusher for crushing, then calcinate at 800°C for 4.5 hours to form calcined dolomite, then use a disc mill to further grind, sieve with a vibrating sieve to obtain dolomite with different particle sizes, pass 1800 After the mesh sieve, it is ready fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com