Method for realizing evenly cooling of strip steel

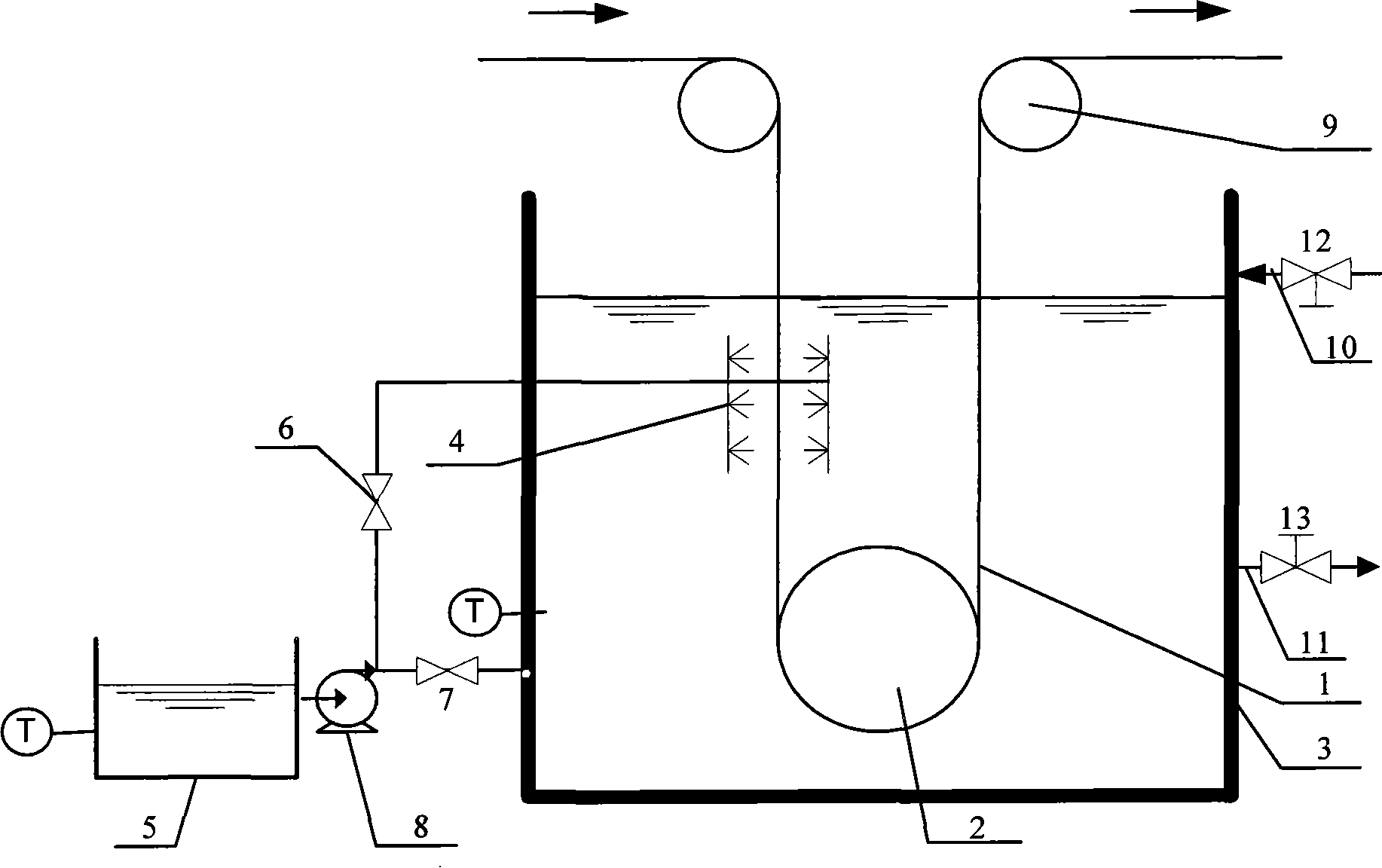

A uniform cooling and strip steel technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of uneven surface cooling, complex technical devices, lack of versatility, etc., achieve good stability and speed, increase cooling speed, The effect of reducing the formation of oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Parameter determination in the jet:

[0030] Concentration 0.02-0.5% and molecular weight 2 million:

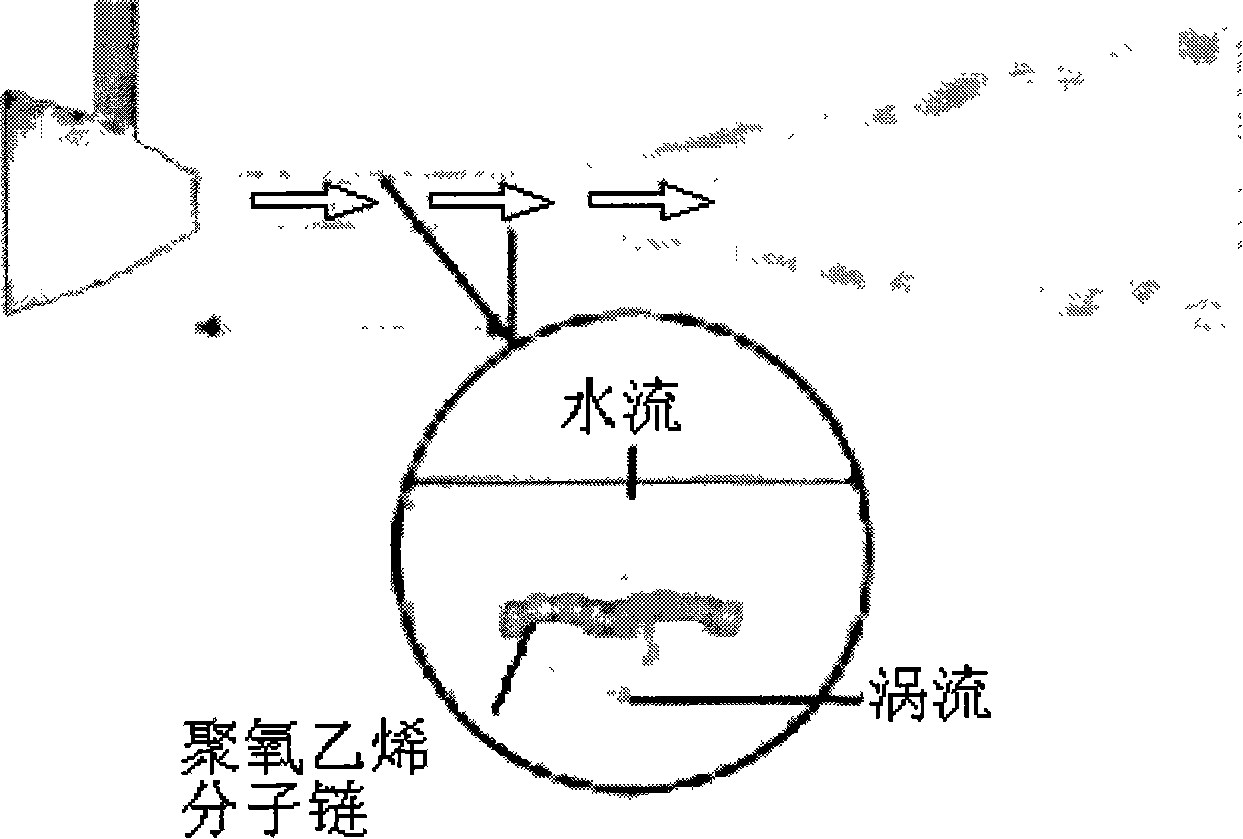

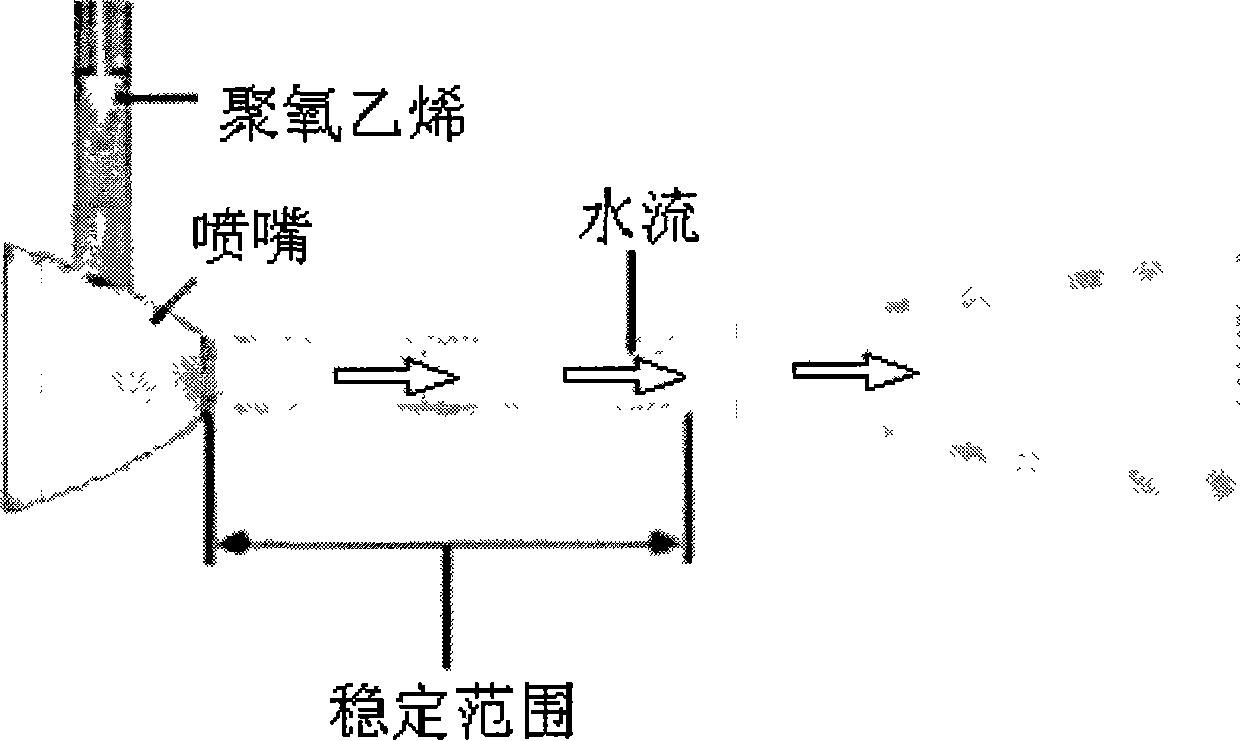

[0031] Based on the known empirical formula, it can be known that polyoxyethylene is added to the jet, and its stable range L is: L=(1+αc)L 0 . α is an empirical constant 2.5×10 2 , c is the relative mass concentration c of polyoxyethylene in water, which must satisfy c≤0.5%. L 0 is the stable range of the water jet in the initial state. The larger the molecular weight, the longer the molecular chain, and the polymer with a molecular weight lower than 2 million cannot effectively eliminate the effect of stabilizing the jet at the boundary of the vortex. figure 2 It shows the vortex phenomenon at the water boundary when no polyoxyethylene is added, and illustrates the role of polyoxyethylene molecular chains in eliminating eddy currents; image 3 Shown is the steady-state jet flow after adding polyoxyethylene to ensure jet velocity and pressure, thereby improving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com