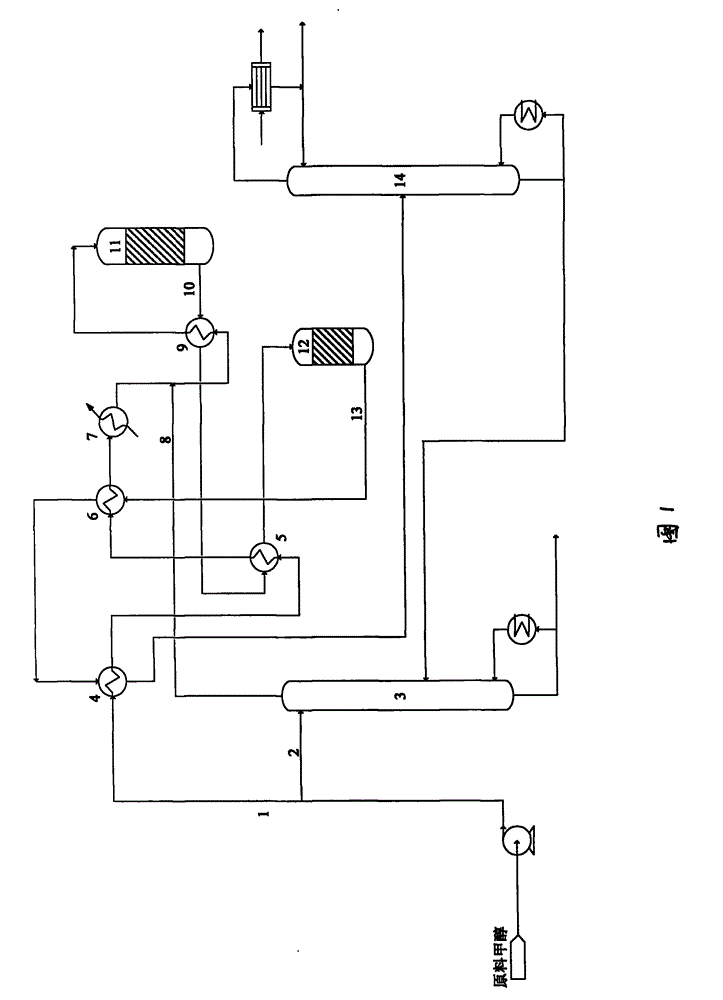

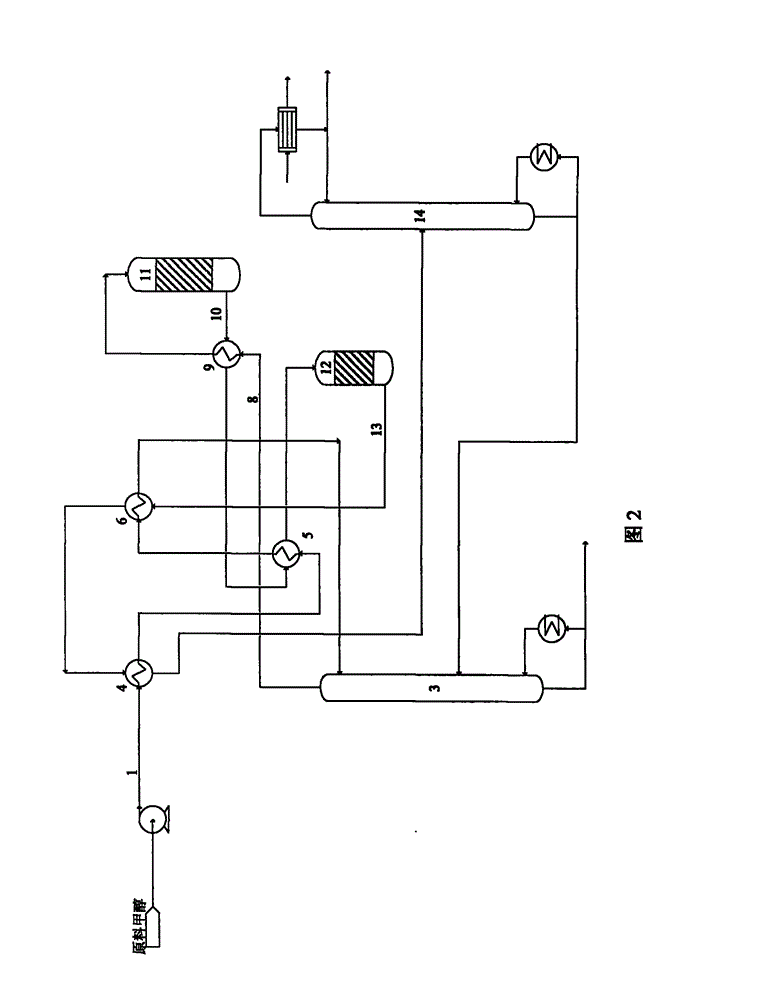

Method for producing two-stage dimethyl ether

A production method and technology of dimethyl ether, applied in the field of ether production technology, can solve the problems of low utilization rate of reaction heat distribution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Two-stage methanol dehydration catalyst and preparation method thereof

[0041] Get 1000g of aluminum chloride solution containing 3% (wt) of aluminum as solution A, use 20g each of lanthanum nitrate and cerium nitrate solutions containing 5% (wt) of La and Ce, and stir to prepare mixed solution B. First add 200ml of deionized water into the reactor, neutralize with 8% (wt) ammonia solution D, control the neutralization temperature at 60-70°C, and the stirring speed at 120r / min. Stop feeding when the pH value reaches 7.5~8.5 (feeding time is about 30 minutes). Then add 200 g of water glass solution C containing 18% of silicon dioxide, the addition time is about 15 minutes, and the pH value is controlled at 8.5 to 9.5. After aging for 2 hours, wash with deionized water until the chloride ion content of the dry basis catalyst is less than 0.5%. After filtration, the filter cake was dried at 120°C for 24 hours and crushed to 250 mesh. Then it was kneaded w...

Embodiment 2

[0044] Embodiment 2: Two-stage methanol dehydration catalyst and preparation method thereof

[0045] Get 1200g of aluminum chloride solution containing 3% (wt) of aluminum as solution A, use 20g each of lanthanum nitrate and cerium nitrate solutions containing La and Ce 5% (wt), and stir to prepare mixed solution B. First add 200ml of deionized water into the reactor, neutralize with 8% (wt) ammonia solution D, control the neutralization temperature at 60-70°C, and the stirring speed at 120r / min. Stop feeding when the pH value reaches 7.5~8.5 (feeding time is about 30 minutes). Then add 170 g of solution C containing water glass 18% of silicon dioxide, the addition time is about 15 minutes, and the pH value is controlled at 8.5 to 9.5. After aging for 2 hours, wash with deionized water until the chloride ion content of the dry basis catalyst is less than 0.5%. After filtration, the filter cake was dried at 120°C for 24 hours and crushed to 250 mesh. Then it was kneaded with...

Embodiment 3

[0046] Embodiment 3: Two-stage methanol dehydration catalyst and preparation method thereof

[0047] Get 1400g of aluminum chloride solution containing 3% (wt) of aluminum as solution A, use 20g of lanthanum nitrate and cerium nitrate solutions containing La and Ce 5% (wt), stir and prepare mixed solution B. First add 200ml of deionized water into the reactor, neutralize with 8% (wt) ammonia solution D, control the neutralization temperature at 60-70°C, and the stirring speed at 120r / min. Stop feeding when the pH value reaches 7.5~8.5 (feeding time is about 30 minutes). Then add 120 g of solution C containing water glass 18% of silicon dioxide, the addition time is about 15 minutes, and the pH value is controlled at 8.5 to 9.5. After aging for 2 hours, wash with deionized water until the chloride ion content of the dry basis catalyst is less than 0.5%. After filtration, the filter cake was dried at 120°C for 24 hours and crushed to 250 mesh. Then it was kneaded with 2% (wt)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com