Environmental protection type inflammable barbecue charcoal and production method thereof

A barbecue charcoal and environmental protection technology, which is applied in the direction of fuel, solid fuel, petroleum industry, etc., can solve the problems of blocked product export, negative impact on environmental protection, large nitrogen emissions, etc., and achieves easy ignition, less waste, and less additives Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

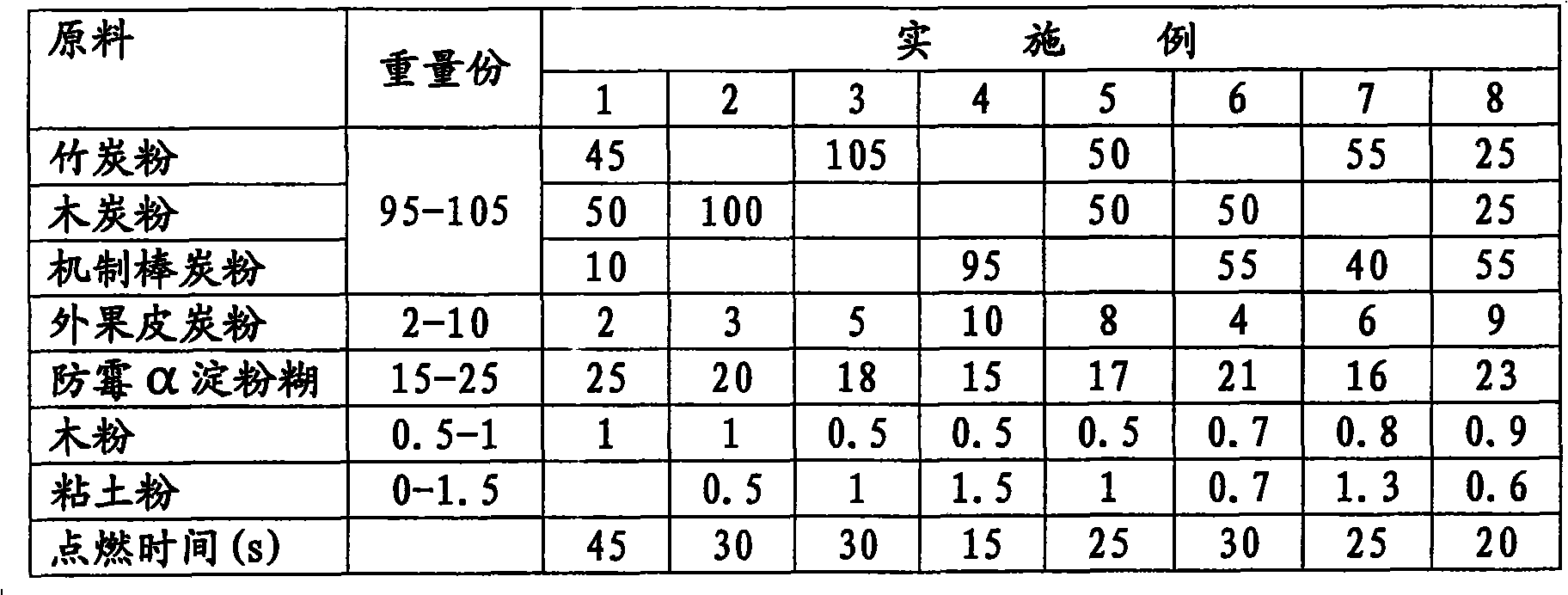

[0015] Embodiment 1 (the corresponding raw material of embodiment 1 and the proportioning value thereof by weight in the comparison table):

[0016] Each raw material should be pulverized according to the granularity required by step (1), and the anti-mold α-starch paste is prepared by the method described in the preparation E. First mix 45 parts of bamboo charcoal powder, 50 parts of charcoal powder, 10 parts of machine-made stick charcoal powder and 2 parts of dried fruit exocarp charcoal powder, then add 1 part of wood flour and mix well, and finally add 25 parts of anti-mold α-starch paste, After stirring evenly, leave it for 5-10 minutes, press it into a honeycomb cake-shaped barbecue charcoal in a machine-made honeycomb cake machine, dry it in the kiln until the moisture content is 3%, and ignite it for 45 seconds.

[0017] What needs to be explained here is that the machine-made stick charcoal is generally made of bamboo and wood chips, and from this expansion, the carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com