Wood-plastic microcellular foamed anion ecological floor and process for producing same

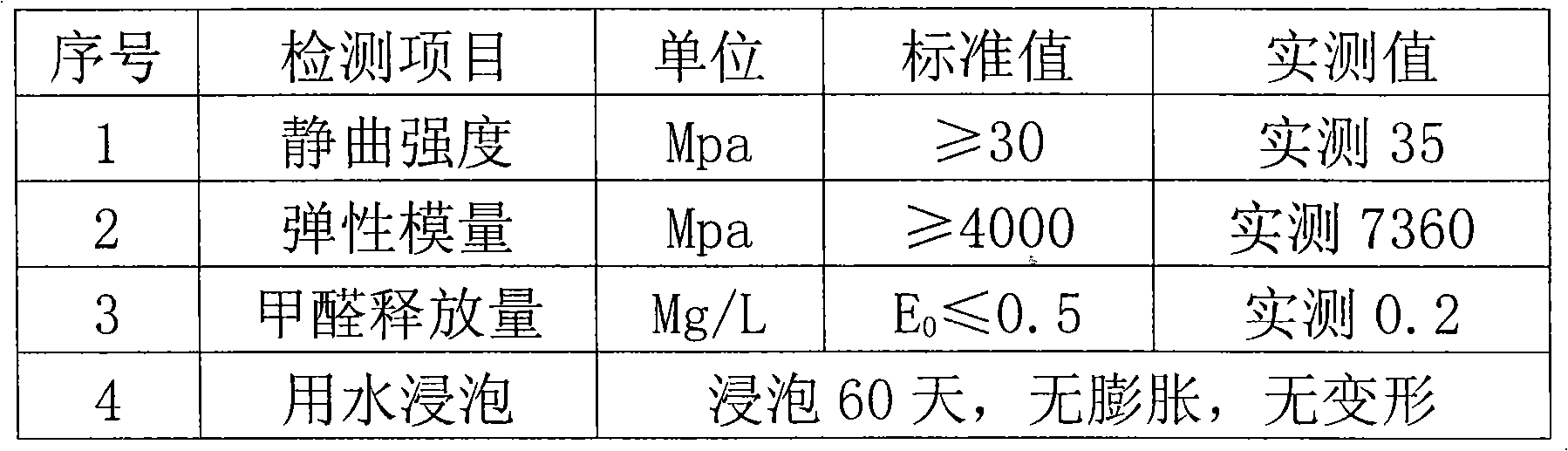

A micro-foaming and negative ion technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of high cost, difficult to popularize and apply, low hardness of the substrate, etc., and achieves strong waterproof performance, enhanced lung function, good Texture and texture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with embodiment.

[0028] The microfoamed negative ion ecological floor provided in this embodiment is made of the following raw materials in parts by weight:

[0029] (1) waste PVC powder: 100 parts;

[0030] (2) Waste tailings: 60 parts;

[0031] (3) Wood flour: 20 parts;

[0032] (4) Auxiliaries: 13.3 parts, including: 1 part of plasticizer, 3.5 parts of heat stabilizer, 0.8 parts of lubricant, 4 parts of foaming agent, and 4 parts of foam regulator;

[0033] (5) Tourmaline tailings powder: 12 parts.

[0034] The chemical composition of the waste tailings sand, in parts by weight, contains: 50-65 parts of silicon dioxide, 2-3 parts of aluminum dioxide, 3.5-4 parts of manganese oxide, 3-3.5 parts of magnesium oxide, 5.5- 6 parts iron, traces of sulfur and phosphorus. During use, it is ground to 400-600 mesh powder with a micropowder mill, and the addition amount is controlled within the specified r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com