A self-imaging double-sided overlay aligning method

A technology of self-imaging and double-sided lithography, which is applied in micro-lithography exposure equipment, photoplate-making process of pattern surface, optics, etc., can solve the problems of low overlay alignment accuracy and complex structure, and overcome the problems of link alignment Influence of accuracy, wide application range, effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

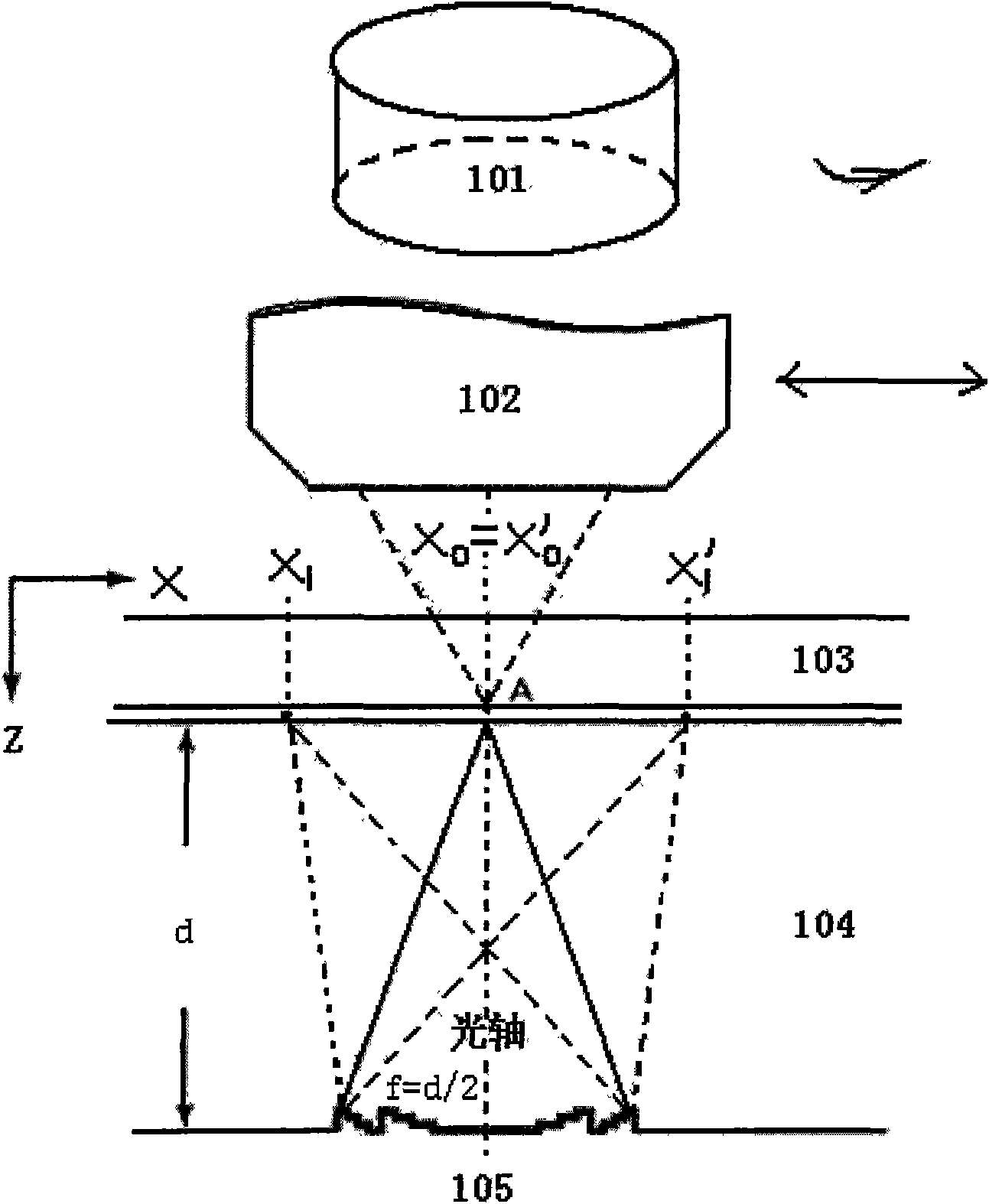

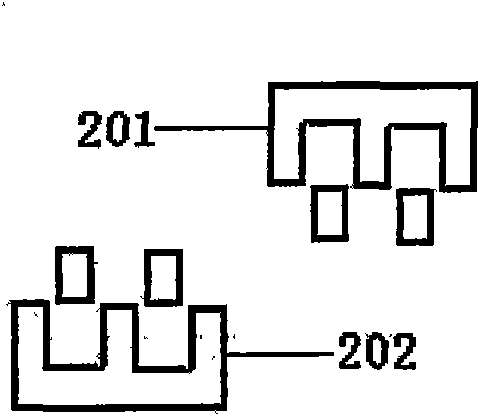

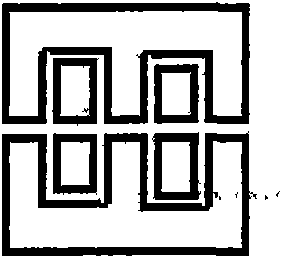

[0016] like figure 1 As shown, the exposure system 101 is located above the reticle 103 and the sample 104, and can be rotated by 180°. When exposure is required, the exposure system 101 is located directly above the reticle 103 and the sample 104. The template 103 and the sample 104 deviate by 90°; the microscope or CCD imaging device and its imaging optical system 102 are located between the exposure system 101, the reticle 103 and the sample 104, can move along the X-axis direction, and are positioned at the reticle 103 and the sample 104 during alignment Directly above, move out of the exposure field of view from the X direction during exposure. In this way, the microscope or CCD imaging device and its imaging optical system 102 can simultaneously capture the image 201 of the reticle alignment mark itself and the contour image 202 formed by the reflective zone plate, as shown in FIG. 2 , to achieve front-side overlay alignment.

[0017] The specific overlay alignment proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com