Supercritical water oxidation reactor

A supercritical water oxidation and reactor technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of structural corrosion of reaction vessels and other equipment, reactor clogging, corrosion intensification, etc., to prevent inorganic salt deposition, complete reaction, and easy operation stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

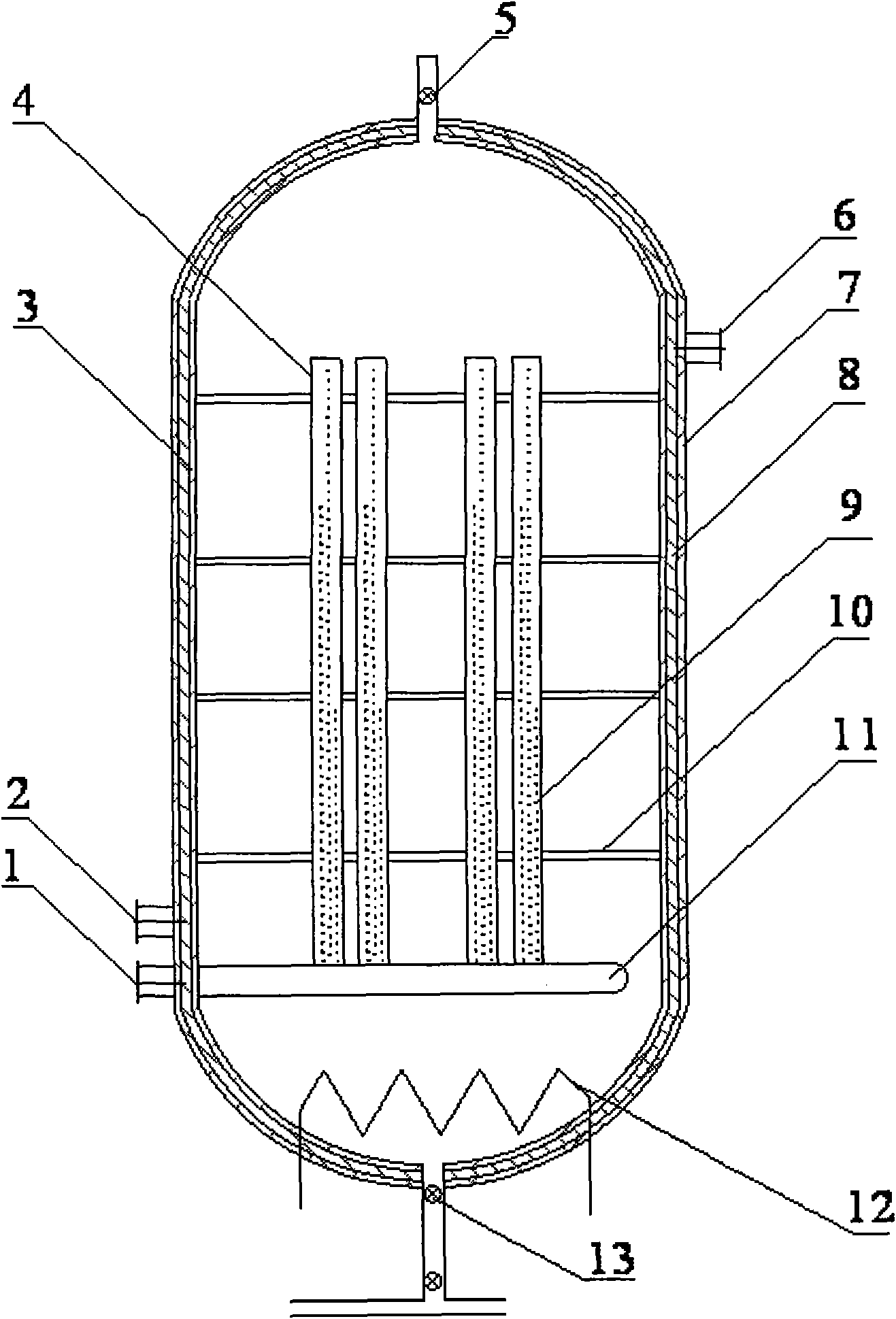

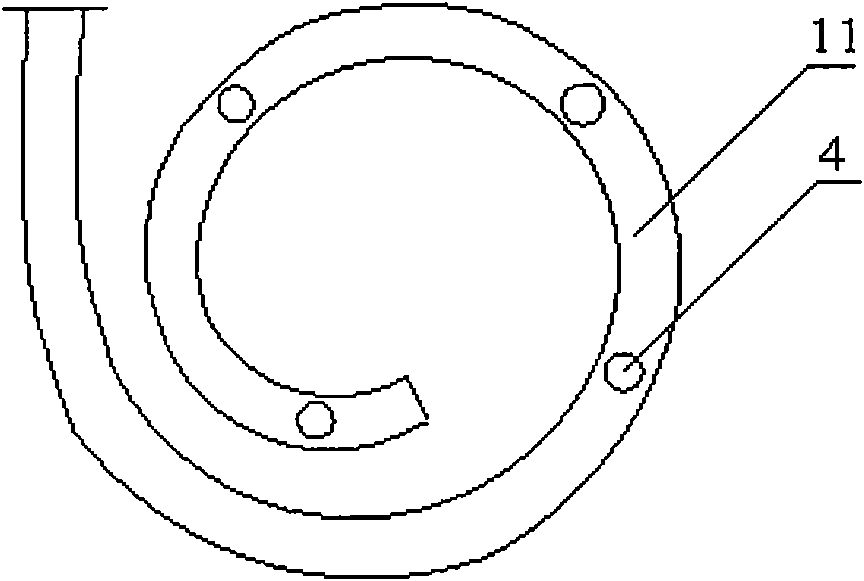

[0028] Such as figure 1 As shown, the supercritical water oxidation reactor consists of a reactor cylinder (3), an oxidant distribution coil (11) and an electric heating device (12); wherein the material of the reactor cylinder is 316L, the height is 6m, and the inner diameter is 0.6 m; The lower part of the reactor cylinder (3) is provided with an oxidant distribution coil (11) made of 316L. The bottom of the reactor cylinder (3) is provided with an electric heating device (12); wherein the top of the reactor is provided with a pressure control valve (5), and the bottom of the reactor is provided with an inorganic salt discharge valve (13). (3) The lower part is provided with the oxidant inlet connection (1) and the waste water inlet connection (2), and the upper part is provided with the clean water outlet connection (6), wherein the oxidant inlet connection (1) and the oxidant distribution coil (11) are connected; the oxidant coil (11) is provided with 4 high 5.8m oxidizer...

Embodiment 2

[0030]When starting, inject a certain amount of ordinary clean water into the reactor with a high-pressure pump, then turn off the high-pressure pump, adjust the pressure control valve (5) to make the pressure in the reactor reach the pressure (30MPa) required by the process, and use the heater (12) to heat. When the pressure reaches 30MPa and the temperature reaches 400°C, turn on the high-pressure liquid oxygen pump, and send the liquid oxygen through the connecting pipe (1), distribute it through the distribution coil (11), and send it into the Reactor, while turning on the waste water pump to inject waste water. Catalytic wastewater with a COD value of 36000mg / L is added to 30MPa by the wastewater pump, then enters the reactor through the connecting pipe (2) at a flow rate of 0.25t / h, and is heated to 400°C by the heater (12). With a flow rate of 50kg / h, the pump enters the reactor from the connecting pipe (1) through the distribution coil (11) and enters the reactor from ...

Embodiment 3

[0032] When starting, first inject a certain amount of ordinary clean water into the reactor with the sludge pump, then close the sludge pump, adjust the pressure control valve (5) to make the pressure in the reactor reach the pressure (30MPa) required by the process, and use the heater (12) to heat . When the pressure reaches 30MPa and the temperature reaches 400°C, turn on the hydrogen peroxide high-pressure pump, pass the hydrogen peroxide through the connecting pipe (1), distribute it through the distribution coil (11), and send it into the reactor from the small hole (9) on the tube (4) , while opening the sludge to inject the sludge. Chemical sludge with a COD value of 80000mg / L is added to 35MPa by a sludge pump, then enters the reactor through the connecting pipe (2) at a flow rate of 0.5t / h, and is heated to 460°C by the heater (12). With a flow rate of 140kg / h, the plug pump enters the reactor from the connecting pipe (1) through the distribution coil (11) and enter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com