Method for preparing polymer-coated nano-cluster core-shell microsphere

A technology of nanoclusters and polymers, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as unstable applications and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1: Synthesis of toluene-phase gold nanoparticles

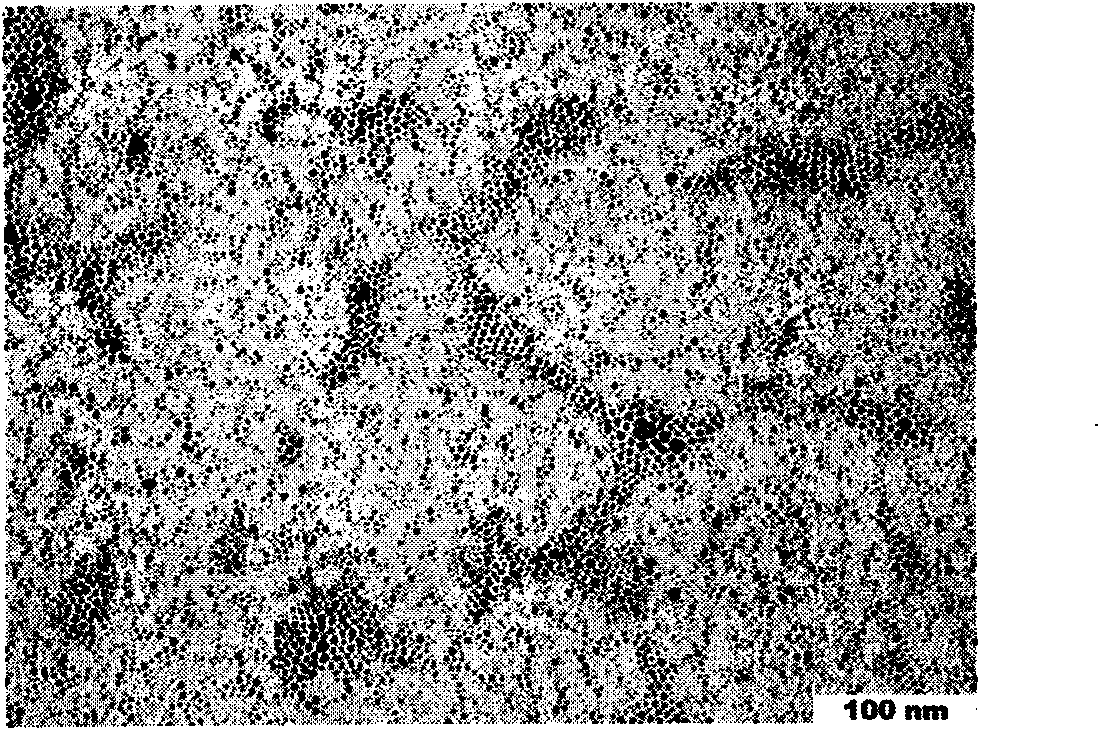

[0032] Gold nanoparticles stabilized by octadecyl p-vinylbenzyl-dimethylammonium chloride (OVDAC) were prepared in chloroform by a two-phase method: first, 105 mg of OVDAC was fully dissolved in 15 ml of chloroform, and mixed with 30mmol / L of HAuCl 4 Mix 5ml of the aqueous solution, stir vigorously for 30min, add 4ml of the aqueous solution containing 64mg of sodium borohydride dropwise, and continue to stir. After the reaction is finished, separate the organic phase with a separatory funnel, remove the chloroform in the system by volatilization and add 15ml of toluene to obtain Gold nanoparticles stabilized by OVDAC in the toluene phase. As shown in Fig. 1(a), we successfully synthesized spherical gold nanoparticles with a diameter of 6 nm in the toluene phase.

[0033] 2: Synthesis of gold nanoclusters

[0034] Get the OVDAC stable concentration of 5ml of the toluene phase prepared by the above steps to be 13mg / ml ...

Embodiment 2

[0038] 1: The method for the synthesis of toluene-phase gold nanoparticles is as described in Example 1

[0039]2: The synthesis of gold nanoclusters is as described in Example 1

[0040] 3: Preparation of polymer-coated gold nanocluster core-shell microspheres

[0041] Using the in-situ polymerization method, mix 0.5ml of the synthesized gold nanocluster aqueous solution with 5ml of 1.14mmol / L pyrrole monomer, stir for 30min, then add 1ml of FeCl-containing 3 80.01g of aqueous solution, the solution turned black at this time, and the solution was stirred for 24 hours. After the reaction was completed, the product was separated from the system by centrifugation under the condition of 30080 rpm. From the scanning electron micrographs and transmission electron micrographs shown in Figure 4(b), we can see that the outer surface of the gold nanoclusters with a size of 100nm-200nm is covered with a polymer shell layer with a thickness of 10nm. The thickness of the polymer shell ...

Embodiment 3

[0043] 1: The method for the synthesis of toluene-phase gold nanoparticles is as described in Example 1

[0044] 2: The synthesis of gold nanoclusters is as described in Example 1

[0045] 3: Preparation of polymer-coated gold nanocluster core-shell microspheres

[0046] Using the method of in-situ polymerization, mix 0.5ml of the synthesized gold nanocluster aqueous solution with 5ml of 2.28mmol / L pyrrole monomer, stir for 30min, then add 1ml of FeCl-containing 3 0.01 g of aqueous solution, the solution turned black at this time, and the solution was continuously stirred for 24 hours. After the reaction was completed, the product was separated from the system by centrifugation under the condition of 3000 rpm. From the SEM and TEM photos shown in Figure 4(c), we can see that the outer surface of the gold nanoclusters with a size of 100nm-200nm is covered with a polymer shell with a thickness of 16nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com