Acidic chemical wastewater pretreating agent and preparation method thereof

A pretreatment agent, acid wastewater technology, applied in the direction of neutralization water/sewage treatment, etc., can solve the problems of high concentration of toxic and refractory organics, deterioration of pretreatment effect, and impact of biochemical treatment, to increase the absolute value of BOD, improve biochemical treatment, etc. Biochemical, low treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

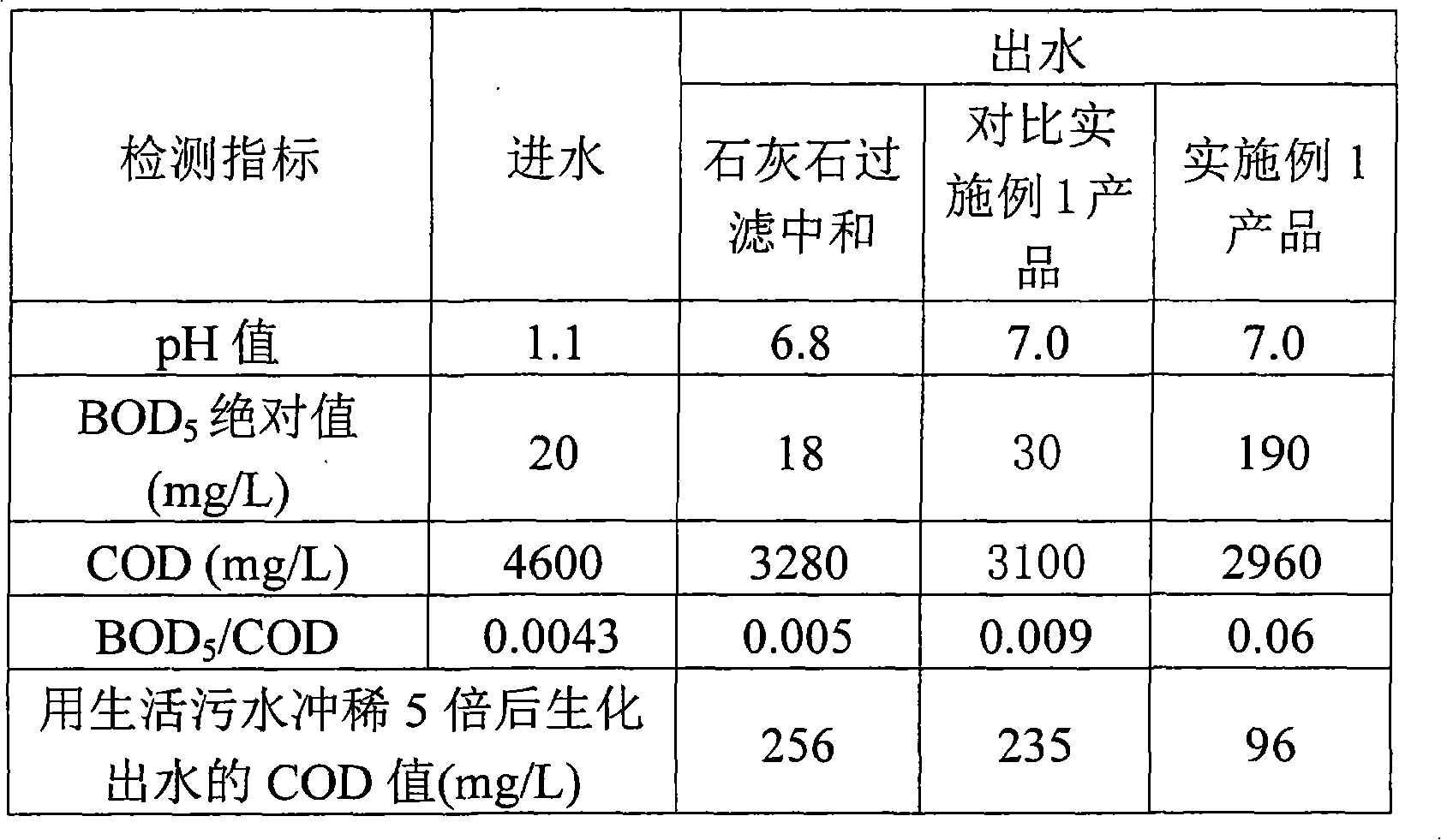

Embodiment 1

[0030] A 500 ml reaction container was placed on a magnetic stirrer, 50 parts by weight of water was put in, and the magnetic stirrer was started, and the temperature of the container was raised to 50°C-60°C. Dissolve 30 parts by weight of sodium hydroxide in the 50 parts by weight of water, slowly add 2 parts by weight of sodium metaaluminate and 3 parts by weight of sodium nitrite while stirring, and add 5 parts by weight of Hangzhou The production waste of Jisheng Seed Breeding Co., Ltd., wherein the starch content in the waste is 12%, the cellulose content is 10%, and the stirring is continued for 30-50 minutes to obtain the described pretreatment agent. The appearance of the product is light yellow liquid, the pH range is 13.5-13.8, and the viscosity range is 1.0-1.5.

Embodiment 2

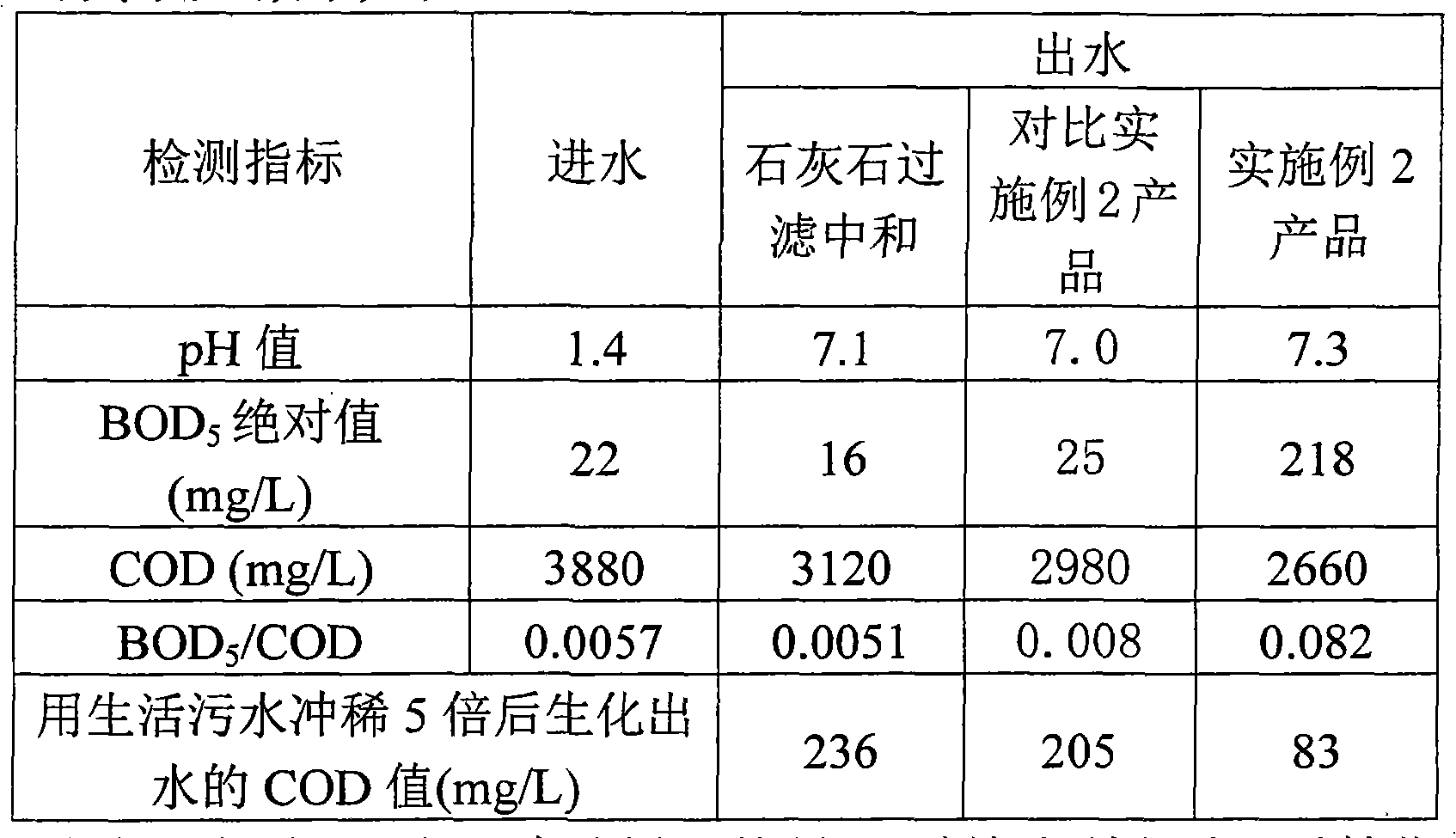

[0038] A 500 ml reaction vessel was placed on a magnetic stirrer, 57 parts by weight of water was put in, and the magnetic stirrer was started, and the temperature of the vessel was raised to 50°C-60°C. Dissolve 33 parts by weight of sodium hydroxide in the water, slowly add 2 parts by weight of sodium metaaluminate and 3 parts by weight of sodium nitrite while stirring, and add 5 parts by weight of winery production waste after completely dissolving , the starch content is 17-23%, and the stirring is continued for 30-50 minutes to obtain the pretreatment agent. The appearance of the pretreatment agent is a light yellow liquid with a viscosity of 1.0-1.5 and a stable time of more than half a year at room temperature and pressure.

Embodiment 3

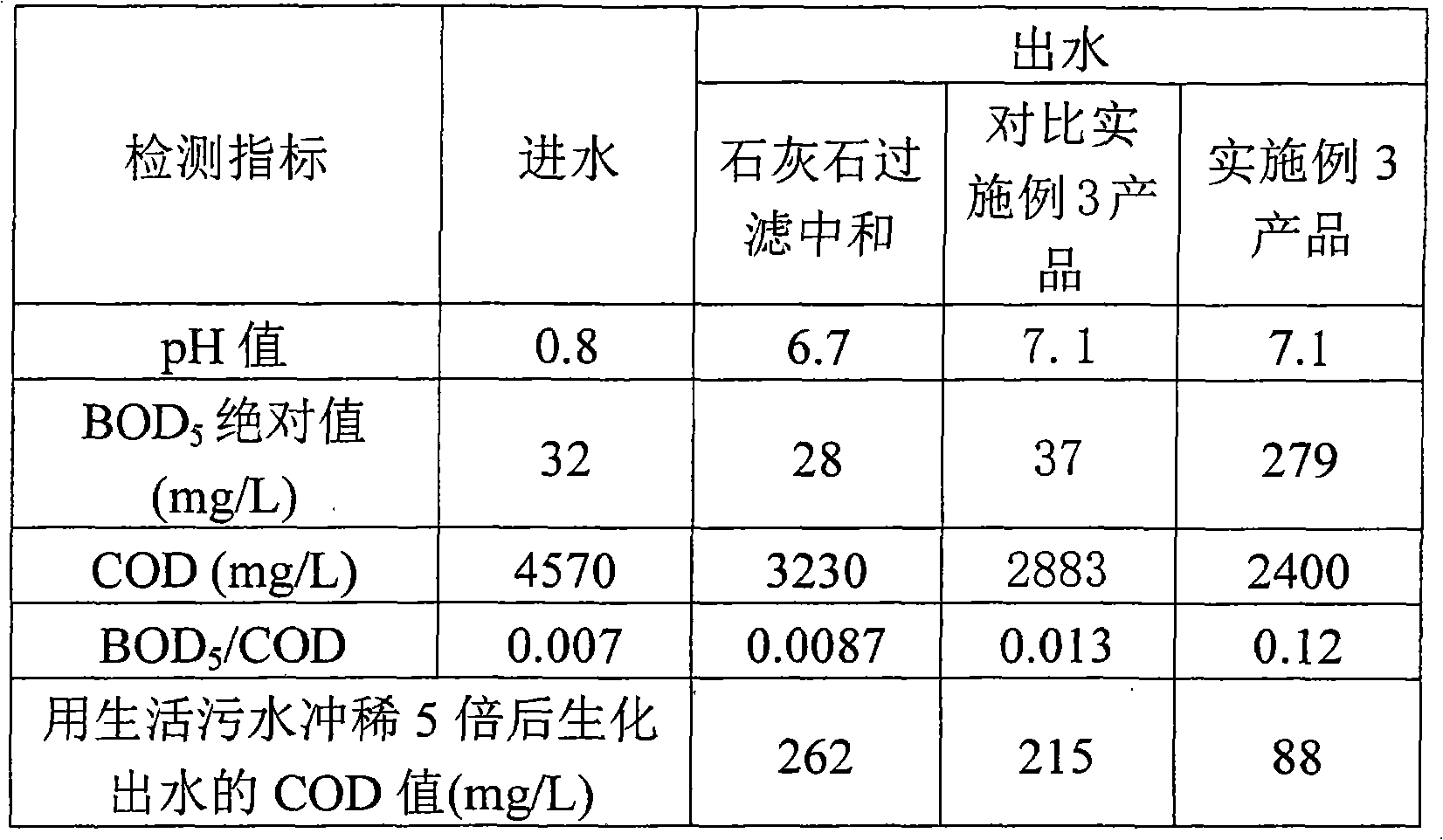

[0046] A 500 ml reaction vessel was placed on a magnetic stirrer, 57 parts by weight of water was put in, and the magnetic stirrer was started, and the temperature of the vessel was raised to 50°C-60°C. Dissolve 31 parts by weight of sodium hydroxide in water, slowly add 3 parts by weight of sodium metaaluminate and 4 parts by weight of sodium nitrite while stirring, and add 5 parts by weight of Xiao Distillery after completely dissolving The waste material, whose starch content is 17-23%, is stirred continuously for 30-50 minutes to obtain the pretreatment agent. The appearance of the pretreatment agent is a light yellow liquid with a viscosity of 1.0-1.5 and a stable time of more than half a year at room temperature and pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com