Method for generating silicon carbide coating on surface of carbon fiber

A technology of silicon carbide coating and carbon fiber, which is applied in the fields of carbon fiber, fiber treatment, textile and paper making, can solve the problems of cost increase and achieve the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

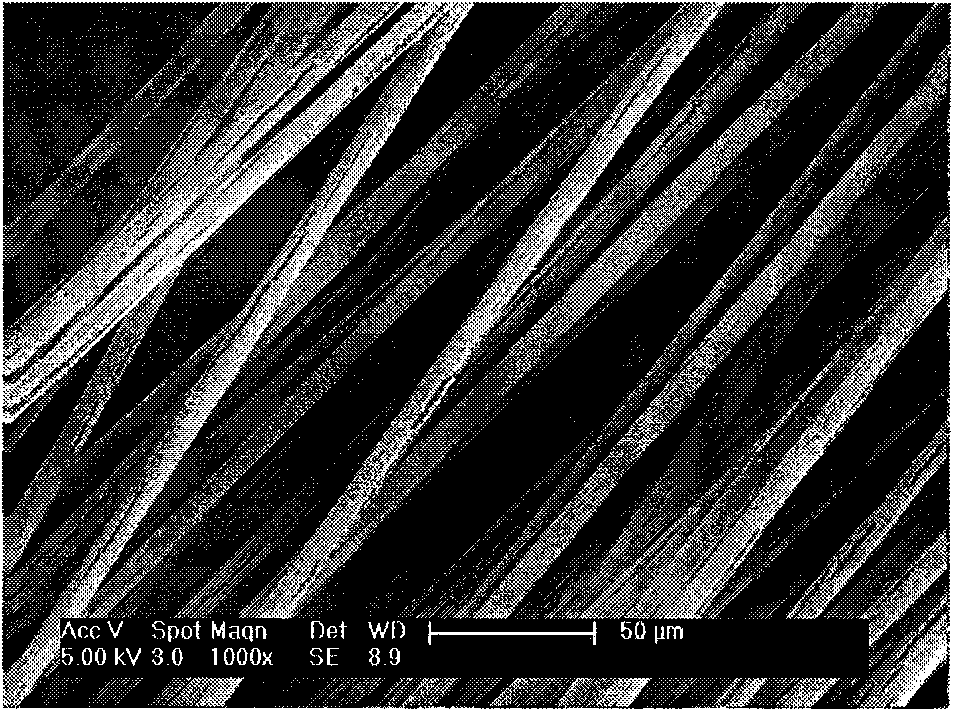

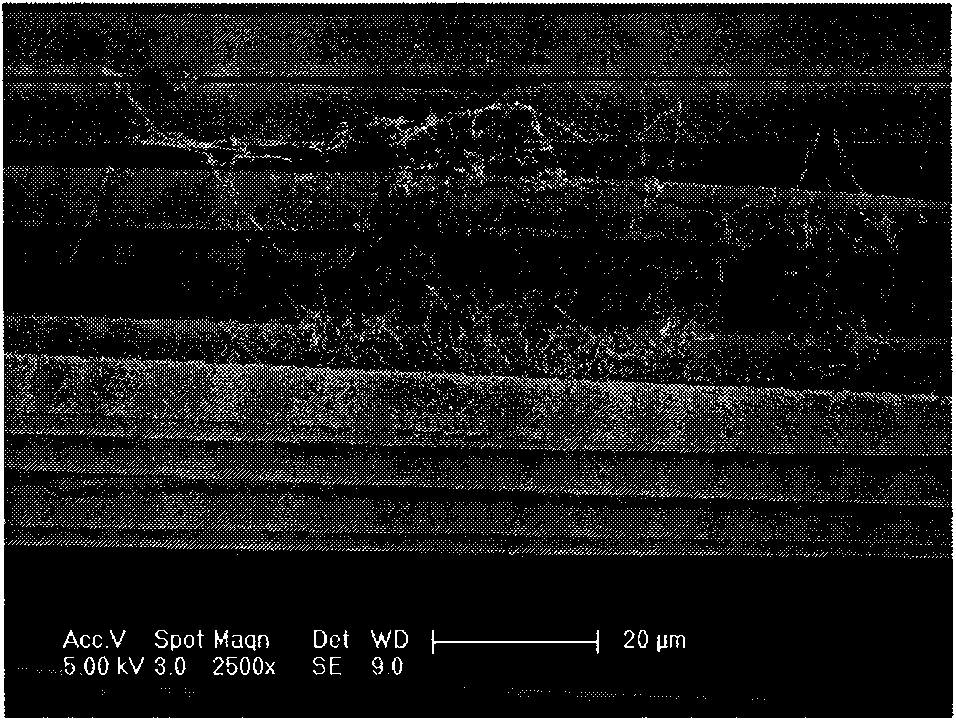

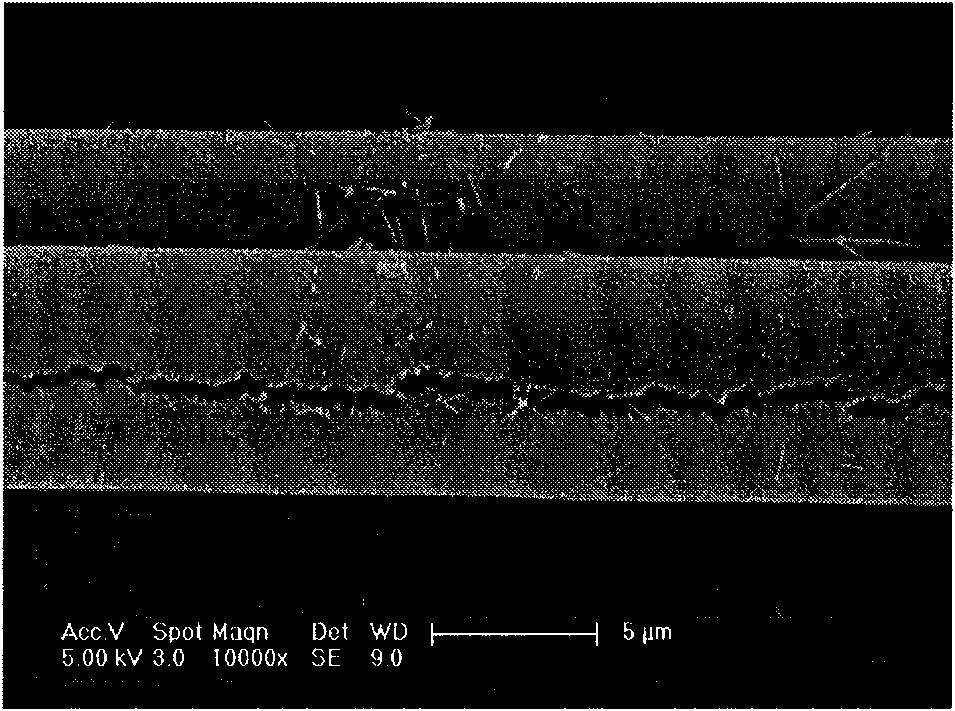

[0012] The invention adopts a simple method of thermally evaporating silicon melt to synthesize SiC coating on the surface of polyacrylonitrile carbon fiber. Put the silicon powder into the bottom of the graphite crucible, and place the polyacrylonitrile carbon fiber horizontally on the top of the crucible. In order to increase the contact between the polyacrylonitrile carbon fiber and the silicon vapor and fix the polyacrylonitrile carbon fiber as much as possible, turn the crucible of the same size upside down On the crucible of polyacrylonitrile carbon fiber, keep certain distance between silicon powder and polyacrylonitrile carbon fiber. Put this device into a high-temperature vacuum sintering furnace, pre-evacuate to 1Pa with a mechanical pump, then fill it with argon protective gas, and then use a mechanical pump and a diffusion pump to evacuate to a vacuum degree of 1×10 -4 Pa, then filled with argon protective gas again, and shut off the argon source. Then heat up to ...

Embodiment 2

[0014] The invention adopts a simple method of thermally evaporating silicon melt to synthesize SiC coating on the surface of polyacrylonitrile carbon fiber. Put the pieces of silicon block into the bottom of the graphite crucible, and place the polyacrylonitrile carbon fiber horizontally on the top of the crucible. In order to increase the contact between the polyacrylonitrile carbon fiber and the silicon vapor and fix the polyacrylonitrile carbon fiber as much as possible, turn the crucible of the same size upside down and place it on a shelf. On the crucible filled with polyacrylonitrile carbon fiber, a certain distance is always maintained between the silicon block fragments and the polyacrylonitrile carbon fiber. Put this device into a high-temperature vacuum sintering furnace, pre-evacuate the mechanical pump to 3Pa, then fill it with argon protective gas, and then use the mechanical pump and diffusion pump to evacuate to a different vacuum degree of 1×10 -2 Pa, then fil...

Embodiment 3

[0016] The invention adopts a simple method of thermally evaporating silicon melt to synthesize SiC coating on the surface of polyacrylonitrile carbon fiber. Put the silicon powder into the bottom of the graphite crucible, and place the polyacrylonitrile carbon fiber horizontally on the top of the crucible. In order to increase the contact between the polyacrylonitrile carbon fiber and the silicon vapor and fix the polyacrylonitrile carbon fiber as much as possible, turn the crucible of the same size upside down On the polyacrylonitrile carbon fiber crucible, a certain distance is always kept between the silicon powder and the polyacrylonitrile carbon fiber. Put this device into a high-temperature vacuum sintering furnace, pre-evacuate the mechanical pump to 5Pa, then fill it with argon protective gas, and then use the mechanical pump and diffusion pump to pump to a different vacuum degree of 1×10 -3 Pa, then filled with argon protective gas again, and shut off the argon sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com