Polyethylenimine nanoparticle-containing microbicidal electrospun polymer fibers for textile applications

A technology of polyethyleneimine and nanoparticles, which can be used in textiles and papermaking, chemical post-treatment of synthetic polymer artificial filaments, textiles, etc., and can solve problems such as non-inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

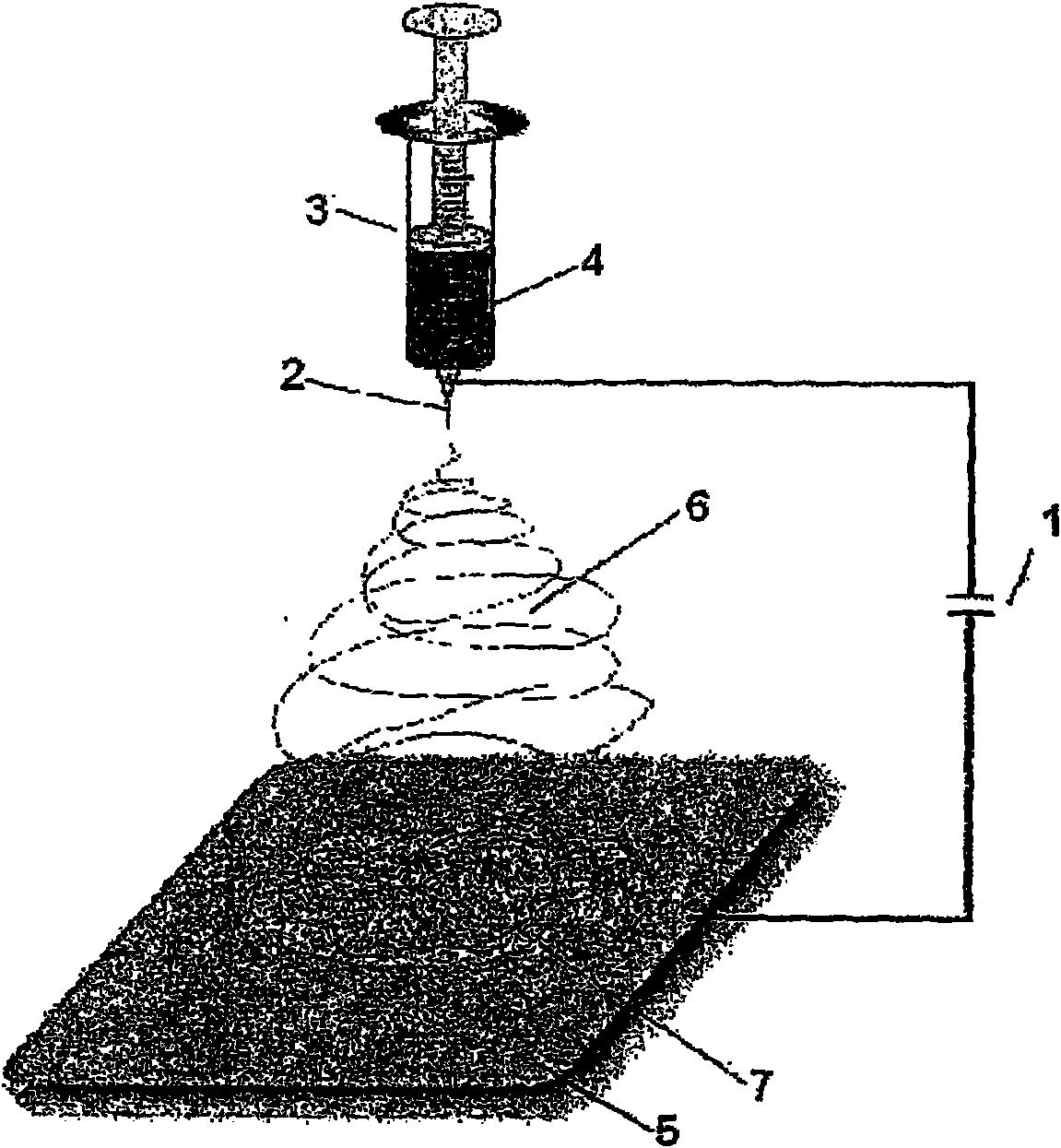

Method used

Image

Examples

Embodiment Construction

[0068] 1. Production of polyethyleneimine nanoparticles

[0069] According to "Mission Accomplished" polyethyleneimine nanoparticles were produced. In this case, 1,5-dibromopentane was used as crosslinker in the first reaction step. In the second reaction step, the alkylation of the crosslinked PEI, 2-bromooctane was used. In the third reaction step - quaternization of the second and third amino groups of PEI, methyl iodide in tetrahydrofuran was used.

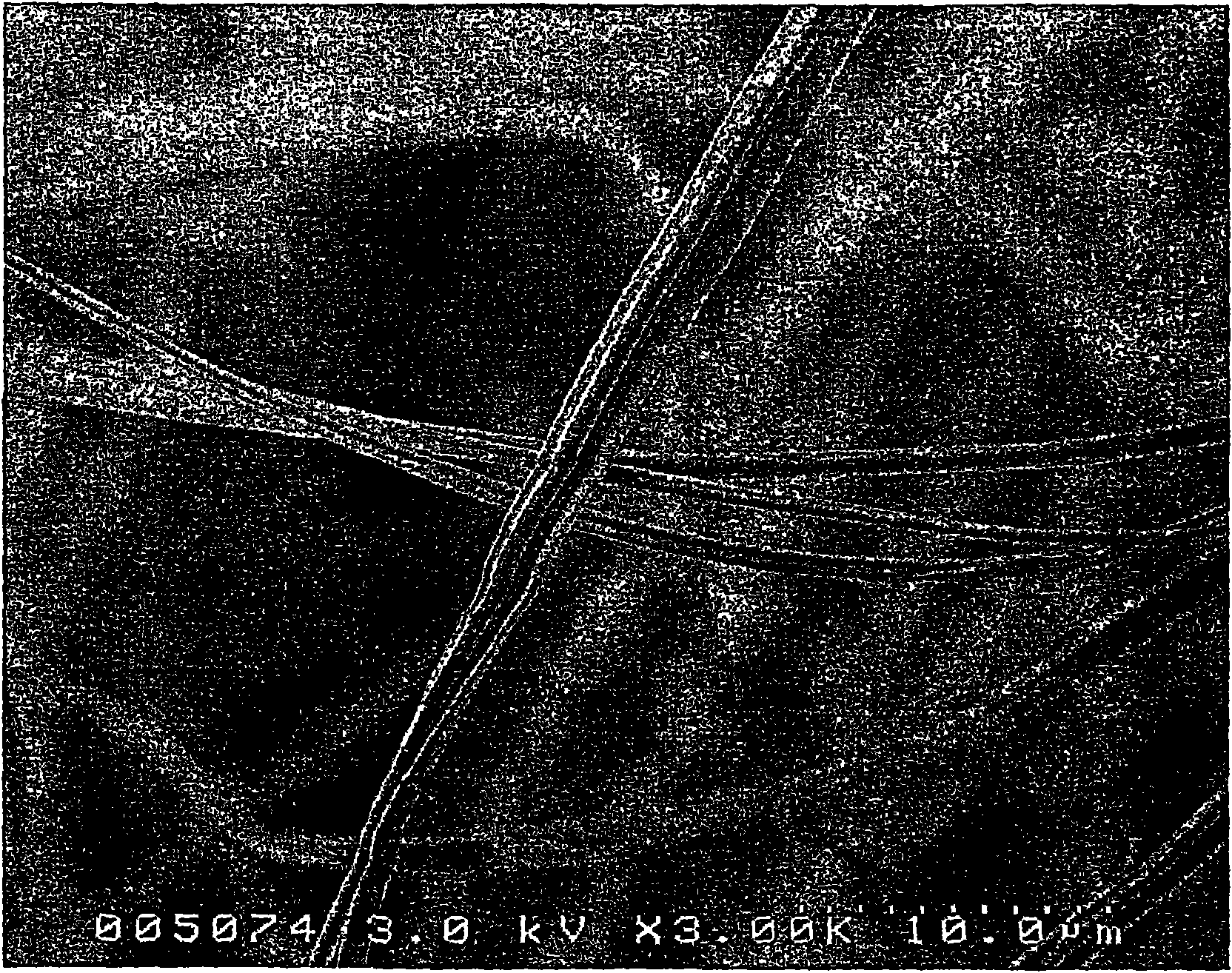

[0070] 2. Production of PVB-based antibacterial nanofibers

[0071] Polyvinyl butyral (PVB, trade name Mowital), a polymer soluble in ethanol, was used.

[0072] Repeating unit of polyvinyl butyral:

[0073]

[0074] First, polyvinyl butyral (Mw=19640, Mn=159000, Mw / Mn=1.23) was dissolved in ethanol by stirring at room temperature. The concentrations of the prepared solutions were 10% by weight and 15% by weight. In order to provide the fibers with an antimicrobial coating, in each case 2% by weight of quaternized PEI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com