Soybean yogurt and preparation method thereof

The technology of soy yogurt and Lactobacillus acidophilus is applied in the directions of milk preparations, dairy products, food preparation, etc., which can solve the problems of low purity of probiotics, long fermentation time, abnormal fermentation, etc., and achieves shortened fermentation time, good effect, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Raw materials: 78.00% soybean milk, 14.898% milk, 6.30% sucrose, 0.10% fructooligosaccharide, 0.70% milk protein powder, 0.001% Bifidobacterium and 0.001% Lactobacillus acidophilus.

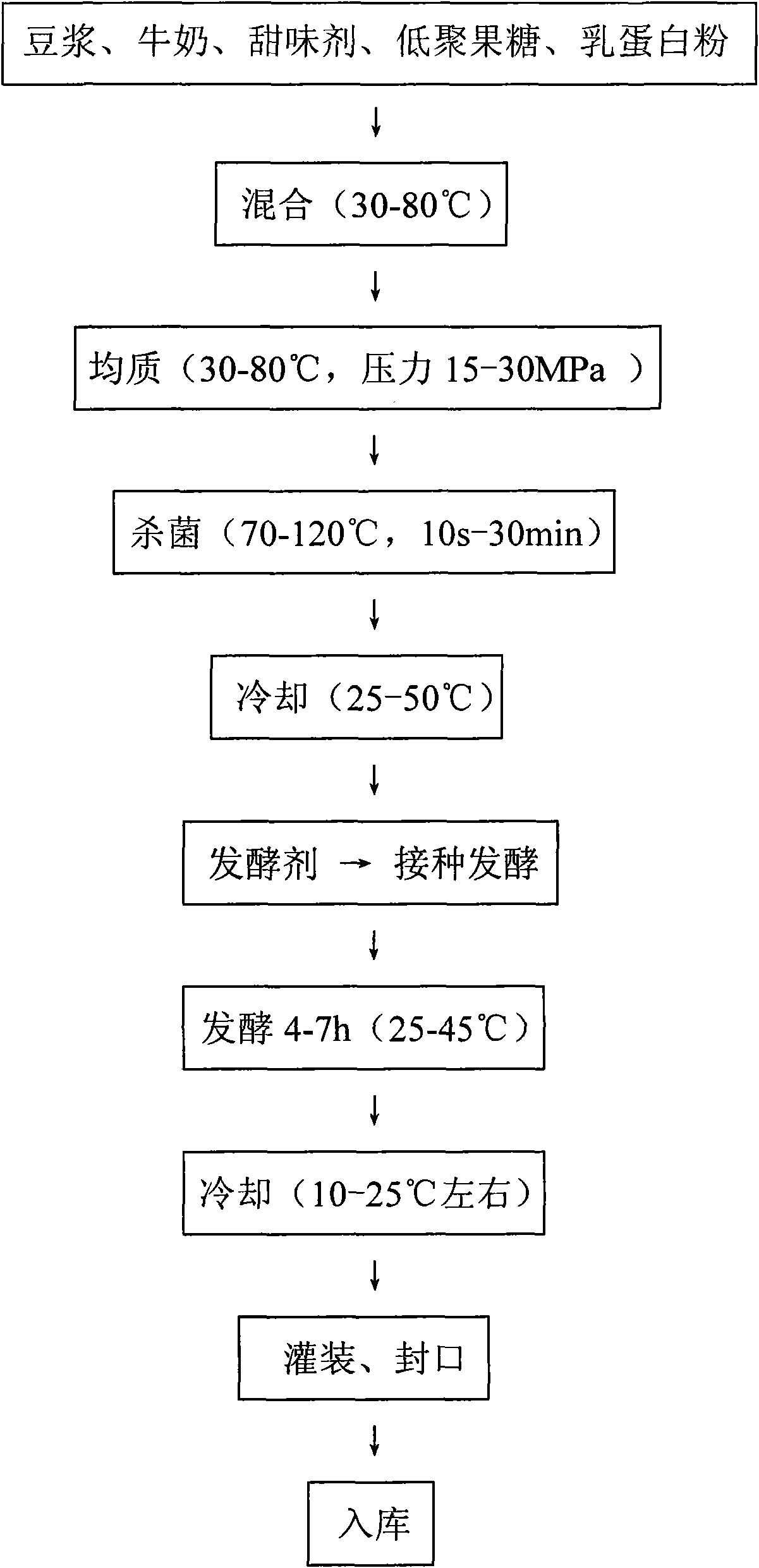

[0049] Preparation:

[0050] (1) Mix soybean milk, milk, sucrose, milk protein powder and fructo-oligosaccharide at 30°C and homogenize at 30°C and pressure of 30MPa;

[0051] (2) Sterilize at 70°C for 30 minutes and cool to 25°C;

[0052] (3) adding Bifidobacterium and Lactobacillus acidophilus, and fermenting at 25° C. for 7 hours;

[0053] (4) Cool to 12°C.

[0054] Soy yogurt indicators: total soluble solids 10.5%, fat 1.42%, protein 2.88%, bifidobacteria 10% 7 cfu / mL and Lactobacillus acidophilus 10 7 cfu / mL; pH=4.3.

Embodiment 2

[0056] Raw materials: 82.296% soybean milk, 12.50% milk, 4.00% sucrose, 0.20% fructooligosaccharide, 1.00% milk protein powder, 0.002% Bifidobacterium and 0.002% Lactobacillus acidophilus.

[0057] Preparation:

[0058] (1) Mix soymilk, milk, sucrose, milk protein powder and fructooligosaccharide at 40°C and homogenize at 40°C and pressure of 22MPa;

[0059] (2) Sterilize at 85°C for 10 minutes and cool to 28°C;

[0060] (3) adding Bifidobacterium and Lactobacillus acidophilus, fermenting at 30°C for 6.8h;

[0061] (4) Cool to 15°C.

[0062] Soy yogurt indicators: total soluble solids 11.0%, fat 1.36%, protein 2.91%, bifidobacteria 10% 7 cfu / mL and Lactobacillus acidophilus 10 7 cfu / mL; pH=4.5.

Embodiment 3

[0064] Raw materials: 91.368% soybean milk, 8.00% milk, 0.03% sucrose, 0.1% fructooligosaccharide, 0.50% milk protein powder, 0.001% Bifidobacterium and 0.001% Lactobacillus acidophilus.

[0065] Preparation:

[0066] (1) Soymilk, milk, sucrose, milk protein powder and fructooligosaccharides were mixed and homogenized at 50°C, the homogenization temperature was 50°C, and the pressure was 18MPa;

[0067] (2) Sterilize at 105°C for 4 minutes and cool to 35°C;

[0068] (3) adding Bifidobacterium and Lactobacillus acidophilus, fermenting at 35°C for 6.5h;

[0069] (4) Cool to 25°C.

[0070] Soy yogurt indicators: total soluble solids 12.5%, fat 1.34%, protein 3.15%, bifidobacteria 10% 7 cfu / mL and Lactobacillus acidophilus 10 7 cfu / mL; pH=4.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com