Preparation method of perovskite-like La*NiO* and applications

A technology of perovskite and species, applied in chemical instruments and methods, catalyst activation/preparation, inorganic chemistry, etc., can solve the non-uniform composition and structure, adjust the uniformity and fineness of the calcined precursor mixture, and affect the performance of calcined products. and other problems, to achieve the effect of uniform particle size and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: raw material is La (AC) 3 ·5H 2 O, Ni(AC) 2 4H 2 O, the prepared soluble salt concentration is 0.10mol / L, according to La(NO 3 ) 3 ·6H 2 O:Ni(NO 3 ) 2 ·6H 2 The molar ratio of O is 2:1 and the two salt solutions are mixed. Take citric acid as complexing agent, concentration is 0.10mol / L, get 500ml complexing agent, according to La(NO 3 ) 3 ·6H 2 O:Ni(NO 3 ) 2 ·6H 2 The molar ratio of O: citric acid is 2:1:3. Add the metal salt solution dropwise to the complexing agent, and perform ultrasonic vibration treatment to form a sol; heat in a water bath at 60°C, stir the sol until it gels; dry at 90°C The product precursor was formed in 10 hours, the product precursor was placed in a microwave synthesis furnace, and treated at 600 ° C for 120 minutes, and the obtained perovskite-like oxide was reduced with hydrogen at 500 ° C for 3 hours to obtain a perovskite-like oxide. Perovskite catalyst La 2 NiO 4 .

Embodiment 2

[0027]Embodiment 2: raw material is La (Cl) 2 ·6H 2 O, Ni(Cl) 2 ·6H 2 O, the prepared soluble salt concentration is 0.10mol / L, according to La(NO 3 ) 3 ·6H 2 O:Ni(NO 3 ) 2 ·6H 2 The molar ratio of O is 2:1 and the two salt solutions are mixed. Take citric acid as complexing agent, concentration is 0.10mol / L, get 500ml complexing agent, according to La(NO 3 ) 3 ·6H 2 O:Ni(NO 3 ) 2 ·6H 2 The molar ratio of O: citric acid is 2:1:3. Add the metal salt solution dropwise to the complexing agent, and perform ultrasonic vibration treatment to form a sol; heat in a water bath at 60°C, stir the sol until it gels; dry at 90°C The product precursor was formed in 10 hours, the product precursor was placed in a microwave synthesis furnace, and treated at 600 ° C for 120 minutes, and the obtained perovskite-like oxide was reduced with hydrogen at 500 ° C for 3 hours to obtain a perovskite-like oxide. Perovskite catalyst La 2 NiO 4 .

Embodiment 3

[0028] Embodiment 3: raw material is La (NO 3 ) 3 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O, the prepared soluble salt concentration is 0.10mol / L, according to La(NO 3 ) 3 ·6H 2 O:Ni(NO 3 ) 2 ·6H 2 The molar ratio of O is 2:1 and the two salt solutions are mixed. Take citric acid as complexing agent, concentration is 0.10mol / L, get 500ml complexing agent, according to La(NO 3 ) 3 ·6H 2 O:Ni(NO 3 ) 2 ·6H 2 The molar ratio of O: citric acid is 2:1:3. Add the metal salt solution dropwise to the complexing agent, and perform ultrasonic vibration treatment to form a sol; heat in a water bath at 60°C, stir the sol until it gels; dry at 90°C The product precursor was formed in 10 hours, the product precursor was placed in a microwave synthesis furnace, and treated at 600 ° C for 120 minutes, and the obtained perovskite-like oxide was reduced with hydrogen at 500 ° C for 3 hours to obtain a perovskite-like oxide. Perovskite catalyst La 2 NiO 4 .

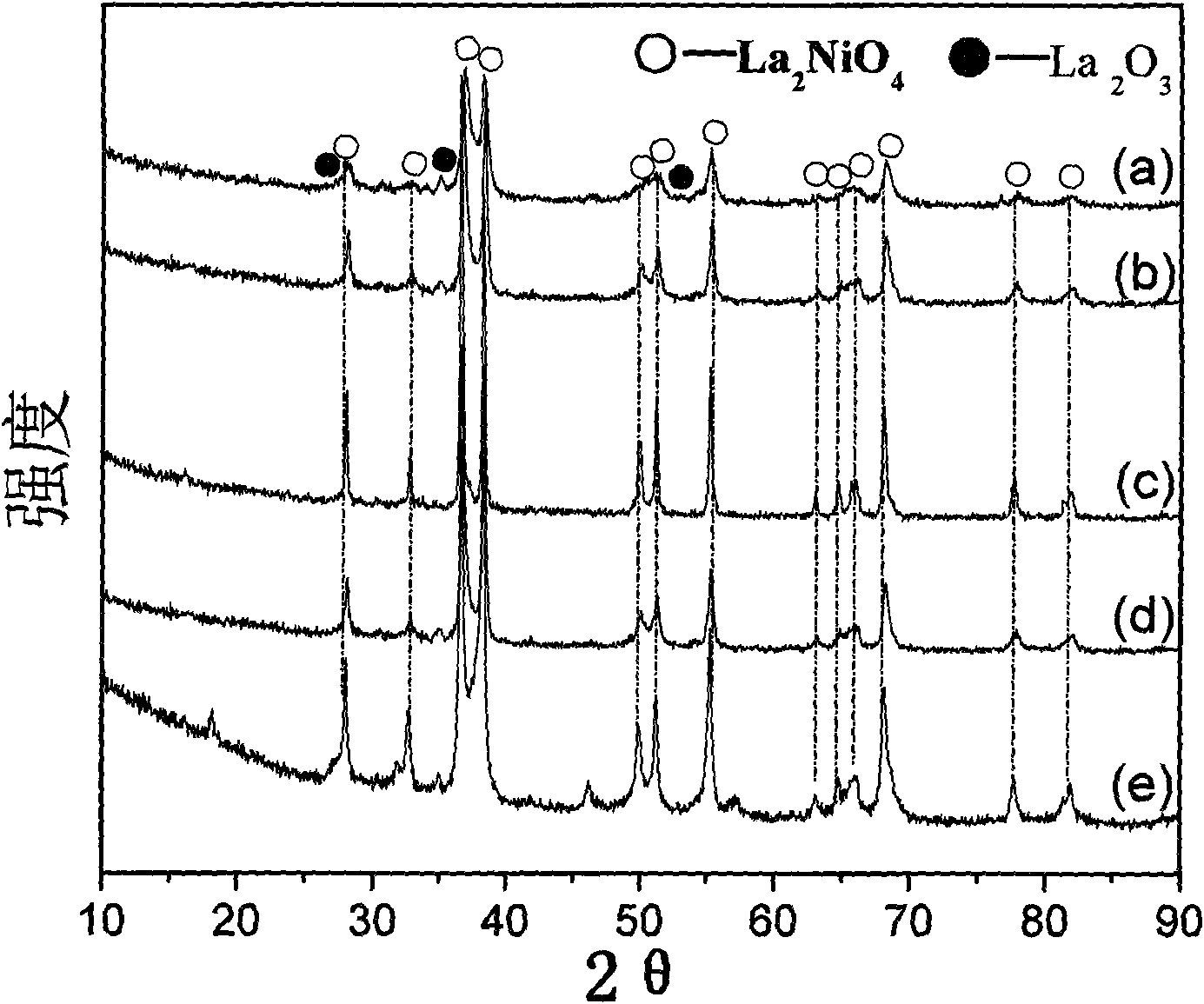

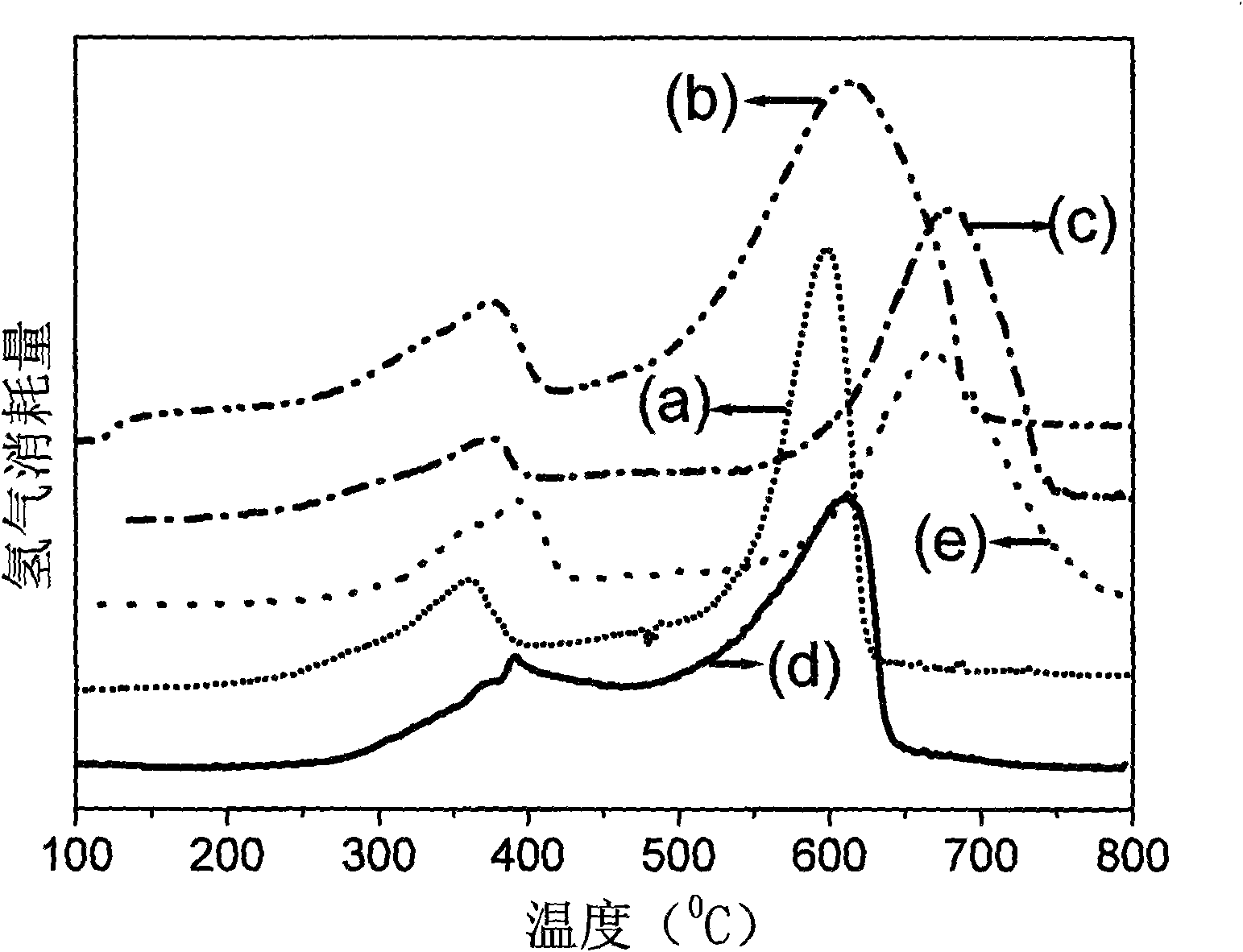

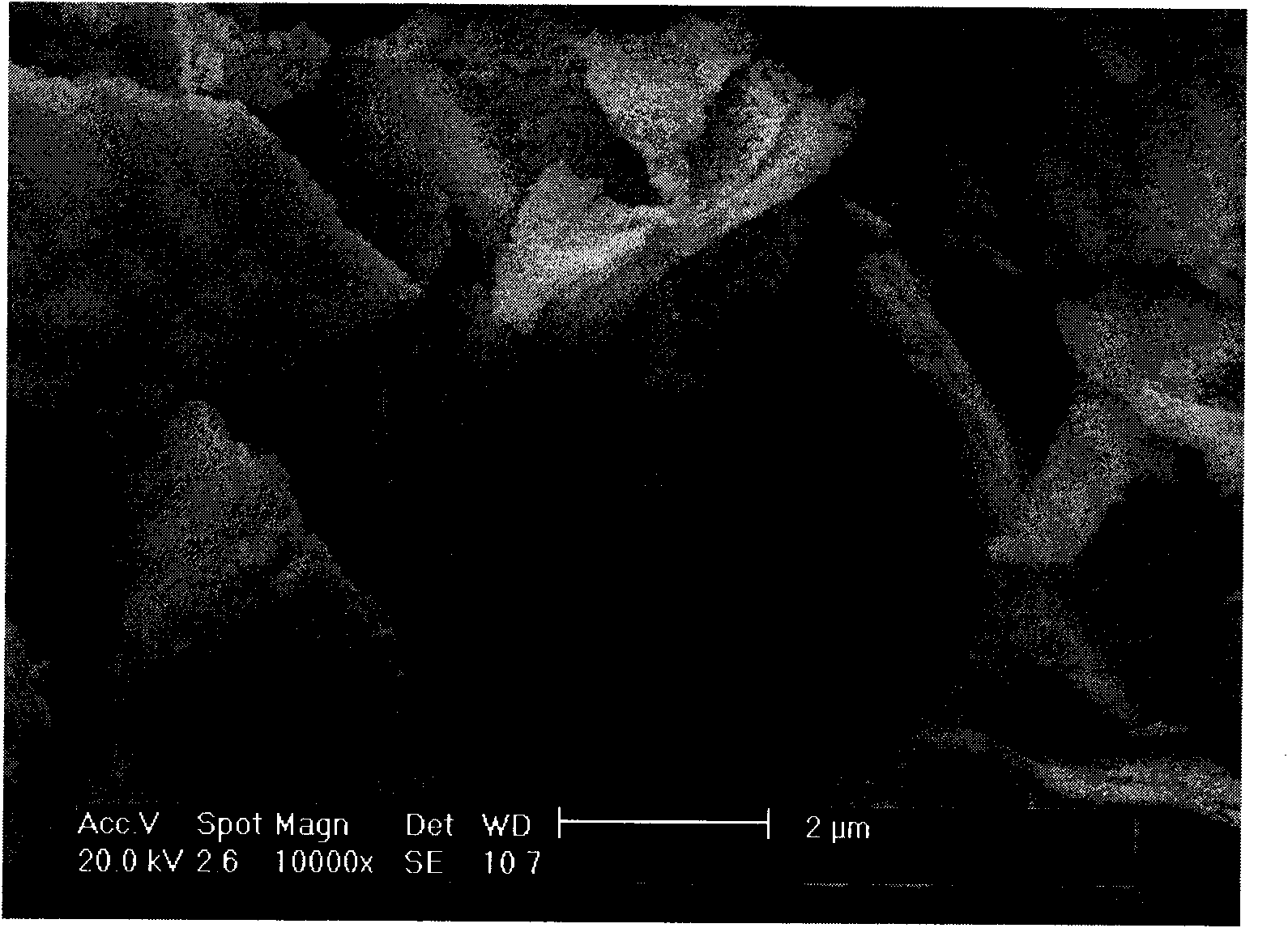

[0029] From figure 1 (a) XRD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com